Underwater releaser

A releaser, seawater technology, applied in underwater operation equipment, transportation and packaging, ships, etc., can solve the safety problems of operators and equipment to be recovered, it is difficult to ensure long-term high reliability, watertightness, and consumables costs. Achieve the effect of avoiding normal and timely release, large bearing capacity, and high watertight reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

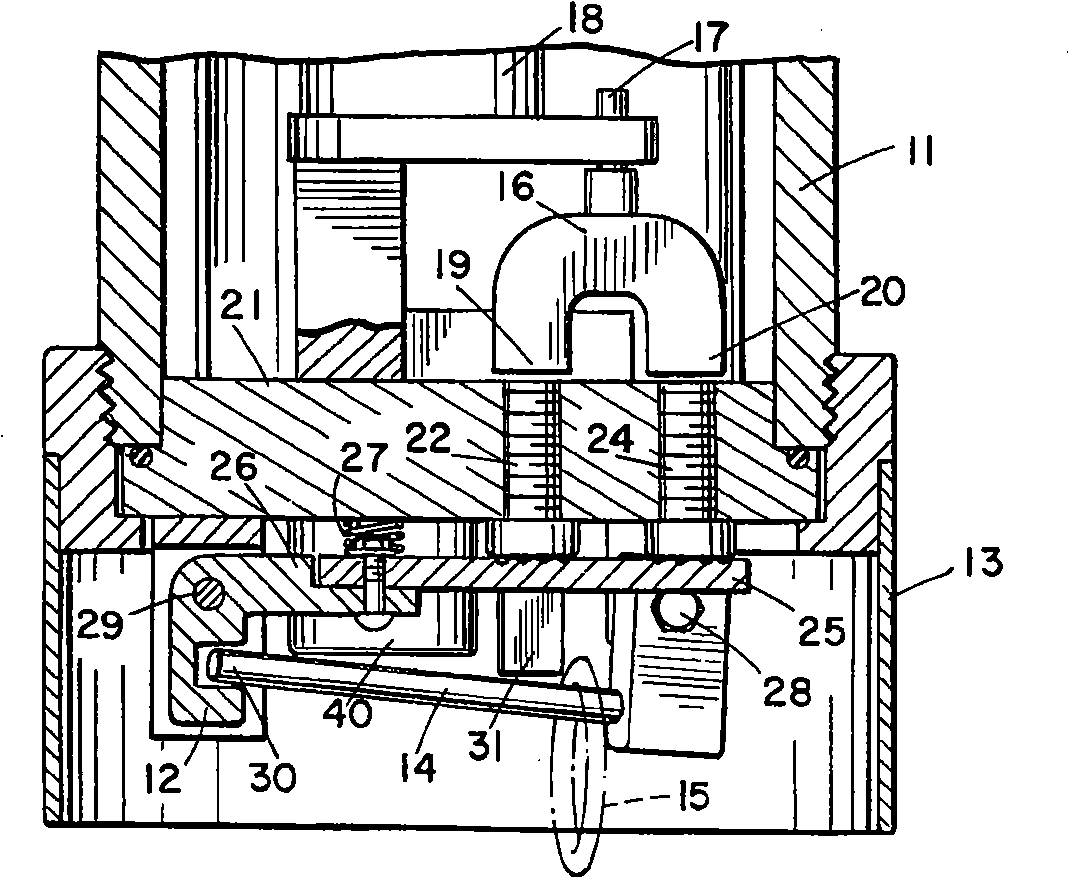

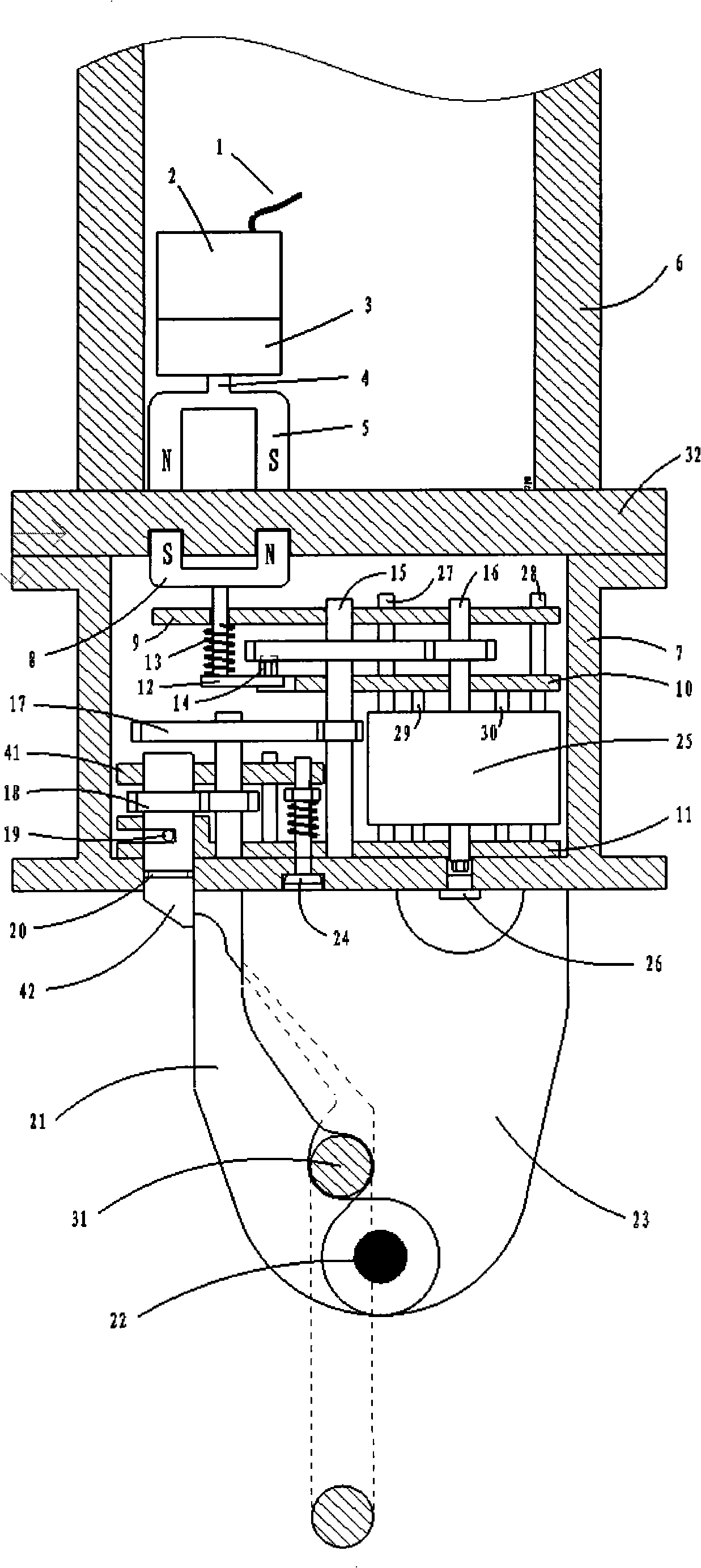

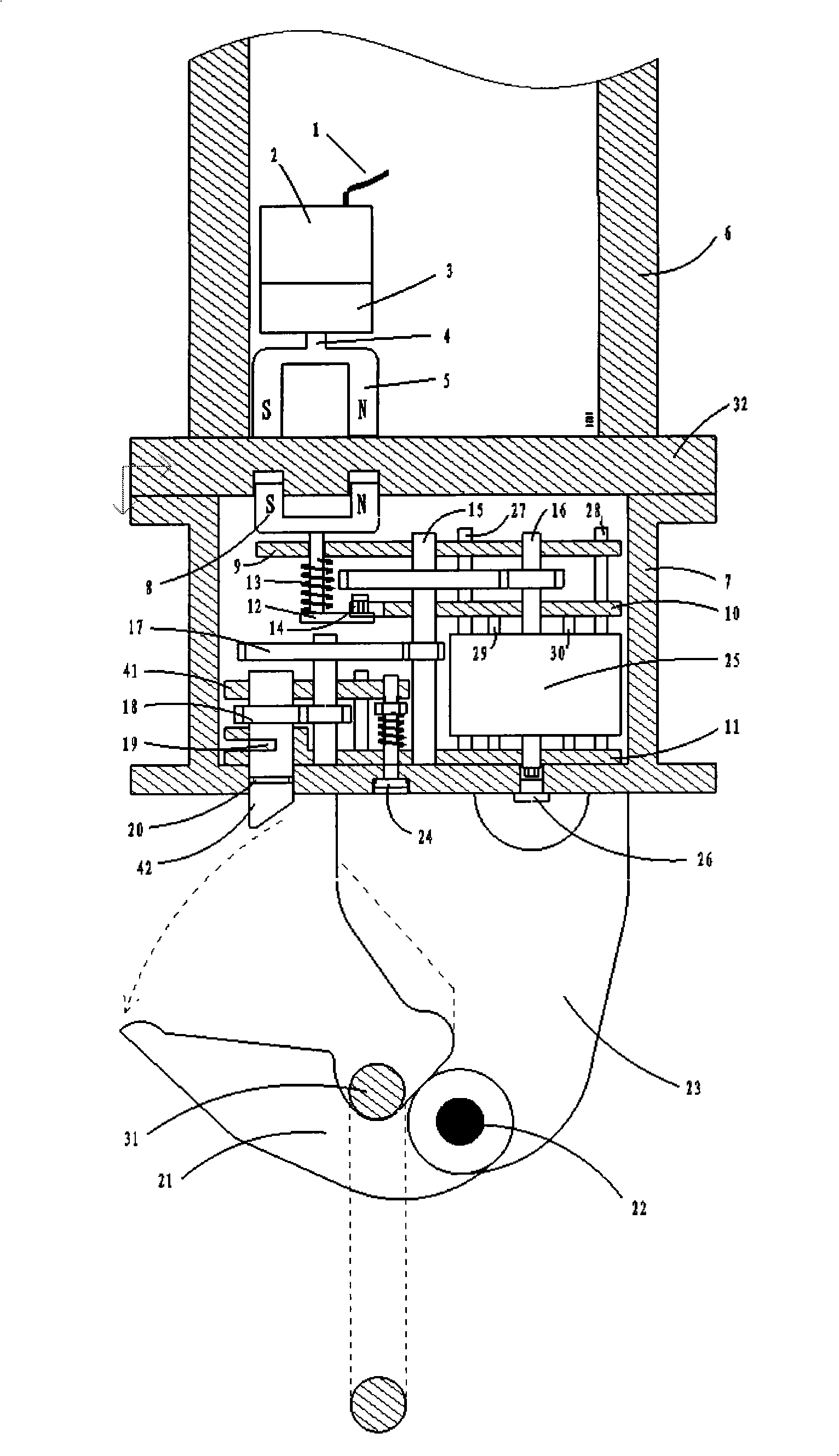

[0035] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0036] The underwater release device of the present invention is composed of eight parts: an electric part, a trigger mechanism, an energy storage mechanism, a deceleration mechanism, a two-way overflow mechanism, a dynamic sealing transmission mechanism and a release arm.

[0037] combine figure 2 . The electric part is located in the pressure chamber, and consists of control wires and cables 1, a DC motor 2, a reducer 3, a connecting shaft 4 and a first "U"-shaped magnetic steel 5. The axis of the connecting shaft 4 is perpendicular to the lower bottom plate 32 of the pressure chamber. The isolation cabin 7 and the lower bottom plate 32 jointly form a seawater isolation cabin section. The seawater isolation compartment is equipped with a two-way overflow mechanism 24, combined with Figure 4 , 33 is a threaded stainless steel bolt, and 34 is a watertight wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com