Special additive for underwater undispersed shrinking-free grouting material

A technology of grouting materials and admixtures, which is applied in the field of building materials, can solve the problems of affecting the quality of grouting, loss of cement slurry, and difficulty in achieving the effect of large fluidity and micro-expansion of grouting materials, and achieves simple construction operations, high strength, Effect of good flow and pourability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

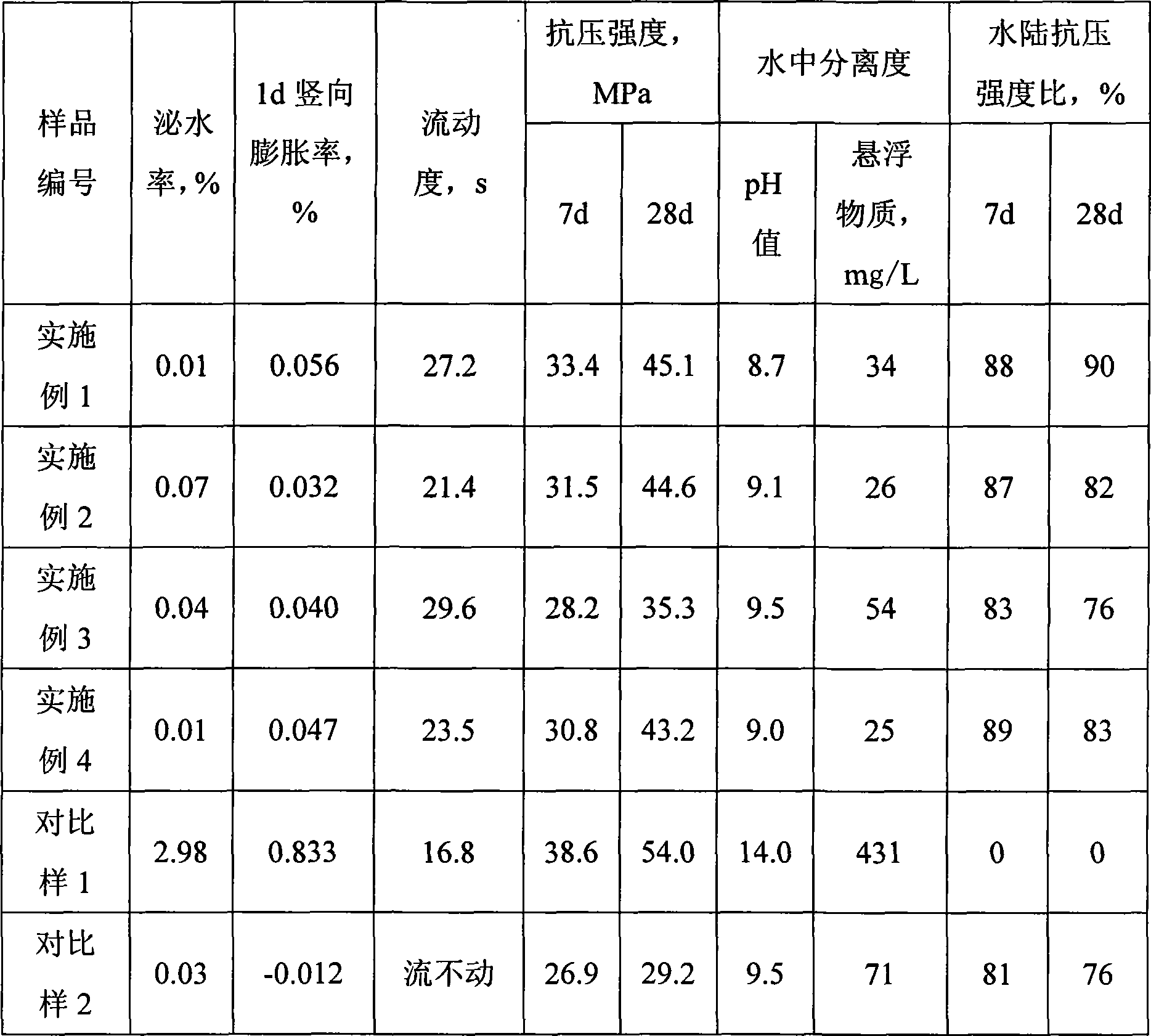

Examples

Embodiment 1

[0042] The special admixtures for underwater non-dispersing and non-shrinking grouting materials are 4% of hydroxypropyl methylcellulose, 3% of polyacrylamide, 15% of polycarboxylate superplasticizer, 24% of UEA expansion agent, 4% of calcium formate, Potassium carbonate 18%, triterpene saponin air-entraining agent 0.06%, zeolite powder 31.94% are prepared by stirring.

Embodiment 2

[0044] Special admixture for underwater non-dispersible and non-shrinking grouting materials, 4% Wenlun glue, 18% sulfamic acid superplasticizer, 4% calcium lignosulfonate superplasticizer, 25% calcium oxide, 28% sodium sulfate, Sodium dodecylbenzene sulfonate 0.25%, silicon powder 10%, fly ash 10.75% and prepared by stirring.

Embodiment 3

[0046] The special admixture for underwater non-dispersing and non-shrinking grouting materials consists of 9% hydroxyethyl methylcellulose, 32% naphthalene superplasticizer, 8% magnesium oxide, 4% UEA expansion agent, 8% calcium formate, and 0.04 aluminum powder %, 15% zeolite powder, and 23.96% fly ash are prepared by stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com