Gripping device for testing pull-power property of low intensity hydrogel

A clamping device, hydrogel technology, applied in the direction of measuring device, strength characteristics, using repeated force/pulsation force to test the strength of materials, etc., can solve the problem of affecting the authenticity of mechanical properties test results, difficult to predict and control penetration depth, Problems such as local stress concentration at the bonding place, to achieve the effect of easy production and promotion, wide application range, and avoidance of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

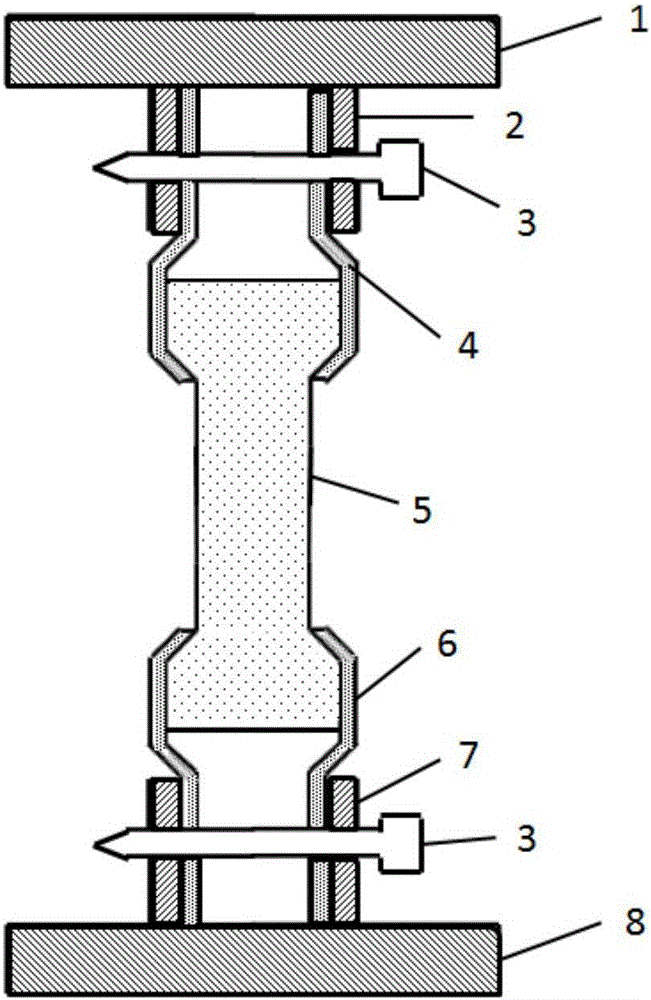

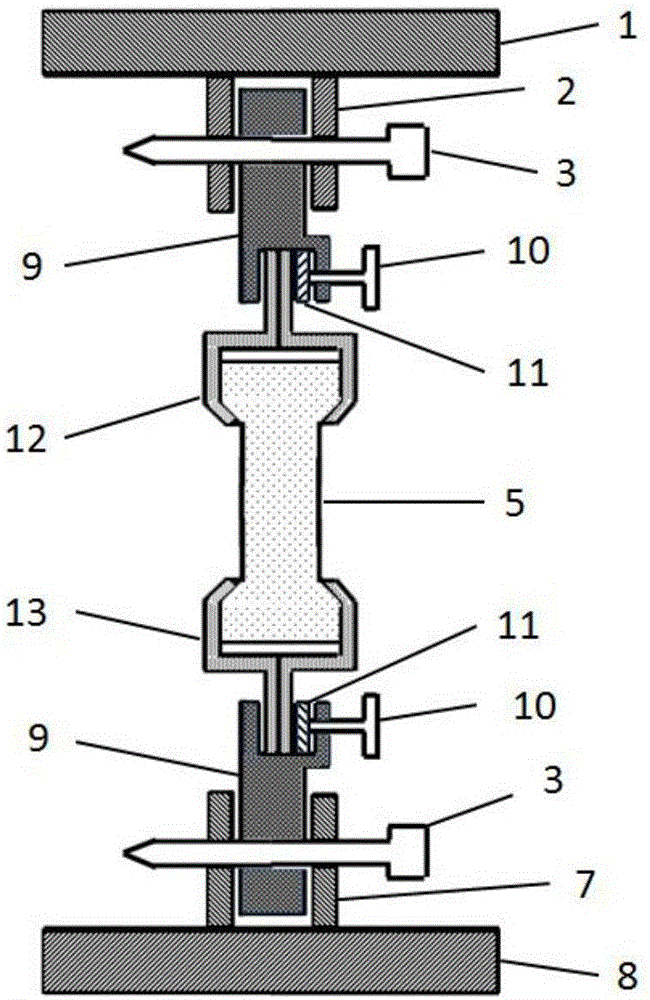

[0034] A clamping device for testing low-strength hydrogel tensile mechanical properties, the clamping device includes a self-made dumbbell-shaped mold, fixture A and accessory parts, or includes a dumbbell-shaped mold, fixture B and accessory parts; considering cost factors , the dumbbell-shaped mold, fixture A and fixture B are all made of aluminum alloy.

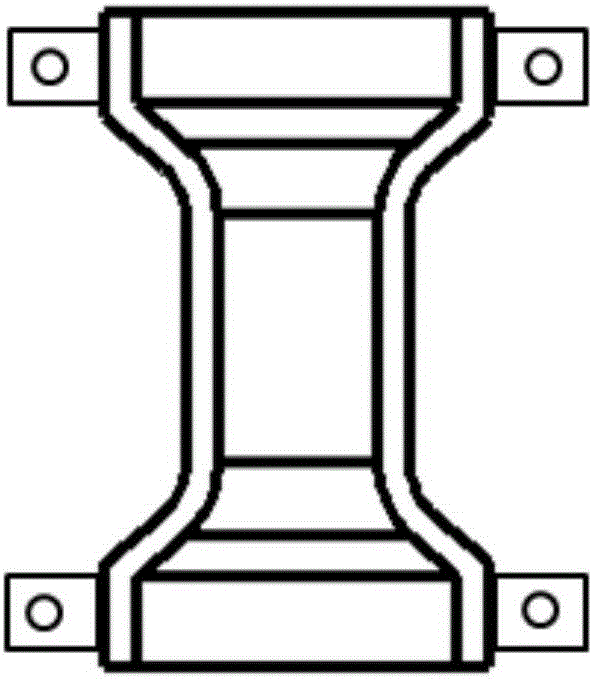

[0035] The two halves of the dumbbell-shaped mold are symmetrically snapped together, such as image 3 As shown in the cross-sectional view of the dumbbell-shaped mold, both sides of the upper and lower parts of the two halves of the dumbbell-shaped mold have flat plates with holes in the middle. After the two halves of the mold are symmetrically fastened, insert bolts into the holes to tighten , to fix the mold. The middle part of the dumbbell-shaped mold is a hollow cylinder, and its length is 6 times of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com