Optical measurement method for strain rate field inside object with parallel front and back surfaces

A technology of front and rear surface and optical measurement, which is applied in the direction of measuring devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

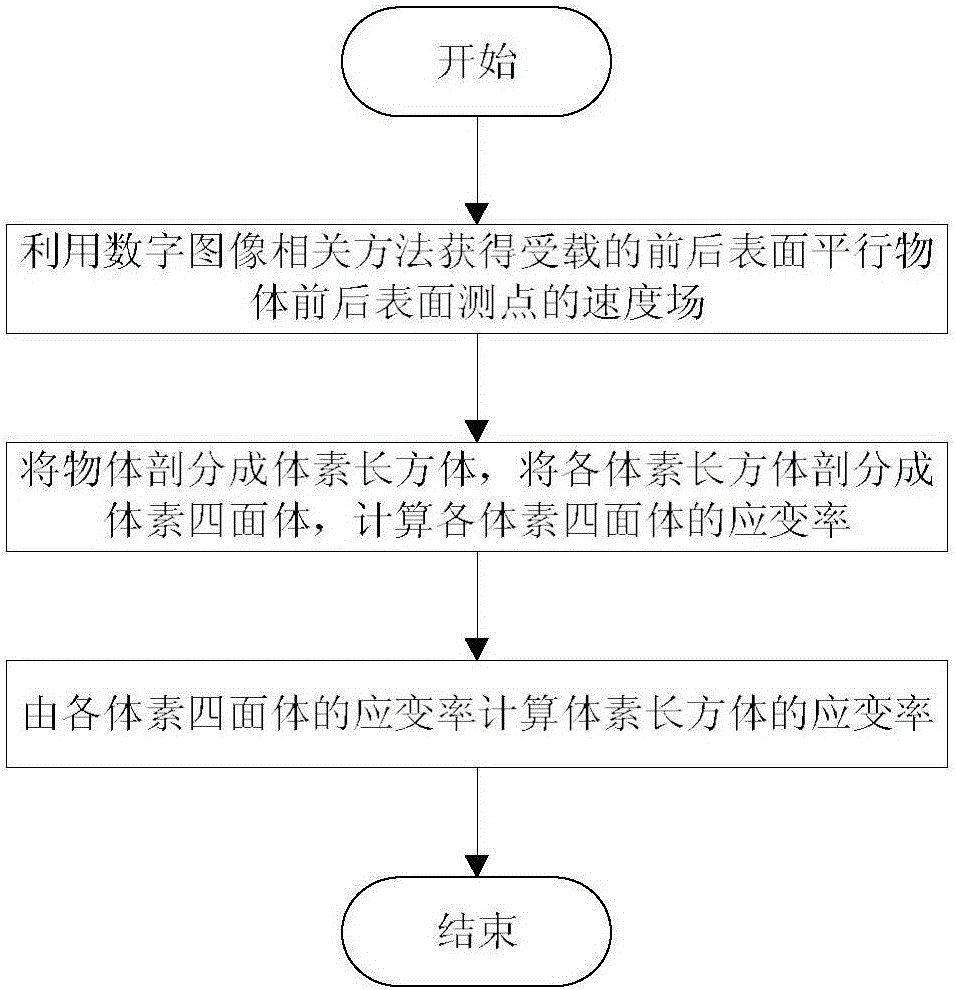

[0035] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An optical measurement method for the internal strain rate field of an object whose front and rear surfaces are parallel. The roadway surrounding rock structure with the front and rear surfaces parallel under the action of compressive stress is selected as an example. The specific steps are as follows, as follows: figure 1 Shown:

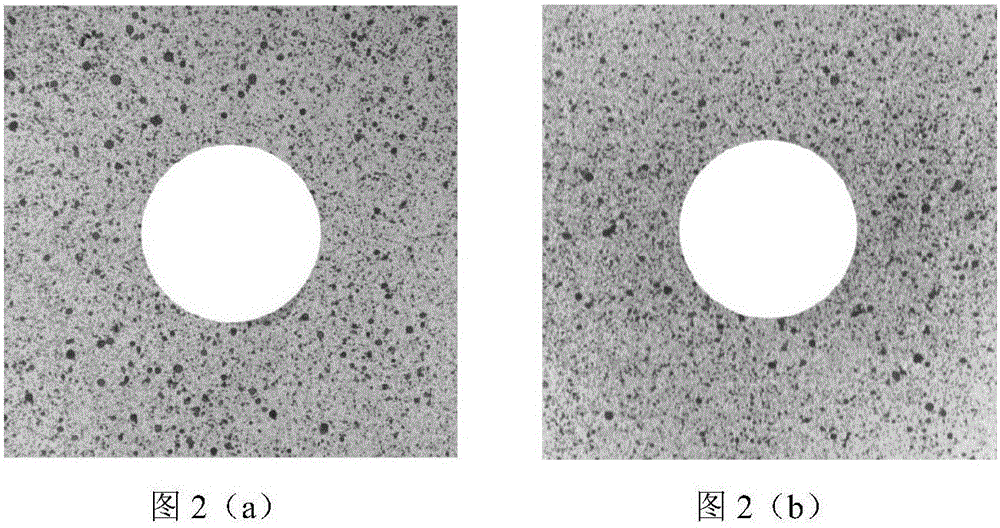

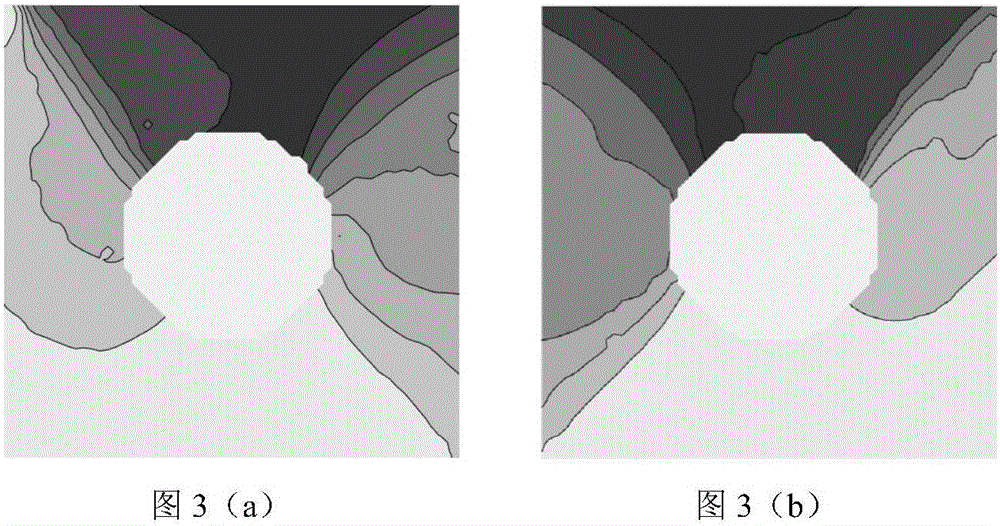

[0036] Step 1, using digital image correlation method to obtain the velocity field of the front and rear surface measuring points of the loaded roadway surrounding rock structure with front and rear surfaces parallel, the present invention is applicable to objects with parallel front and rear surfaces, and the present embodiment selects the roadway surrounding rock structure with parallel front and rear surfaces;

[0037] Step 1.1. If the front and rear surfaces of the surrounding rock structure of the roadway wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com