Shale gas horizontal-well refracturing temporary-plugging critical pressure testing method

A critical pressure, re-fracturing technology, applied in earth-moving drilling, wellbore/well components, production fluids, etc., can solve the problem of not establishing the critical pressure simulation of temporary plugging, the judgment of the critical pressure that cannot be temporarily plugged, and the inability to fully simulate the formation conditions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further specifically described below through examples and in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

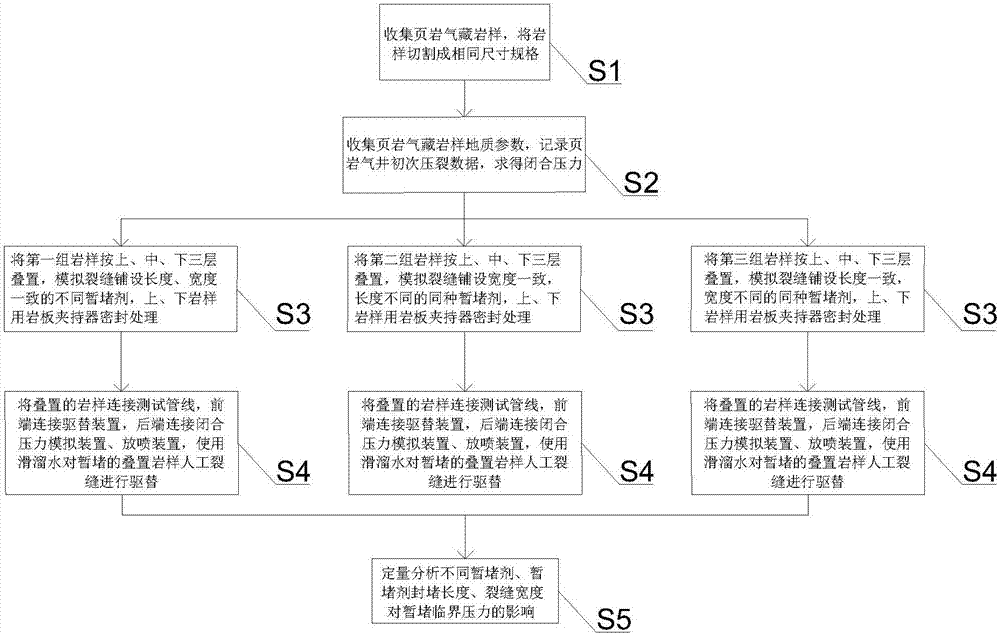

[0030] Such as figure 1 As shown, the present invention relates to an experimental testing method for the temporary plugging critical pressure of repeated fracturing of a shale gas horizontal well, which mainly includes the following steps:

[0031] S1. Collect rock samples from shale gas reservoirs, cut the rock samples into the same size and specifications, and prepare for the next experimental test;

[0032] S2. Collect geological parameters of rock samples in shale gas reservoirs, record initial fracturing data of shale gas wells, and obtain fracture closure pressure;

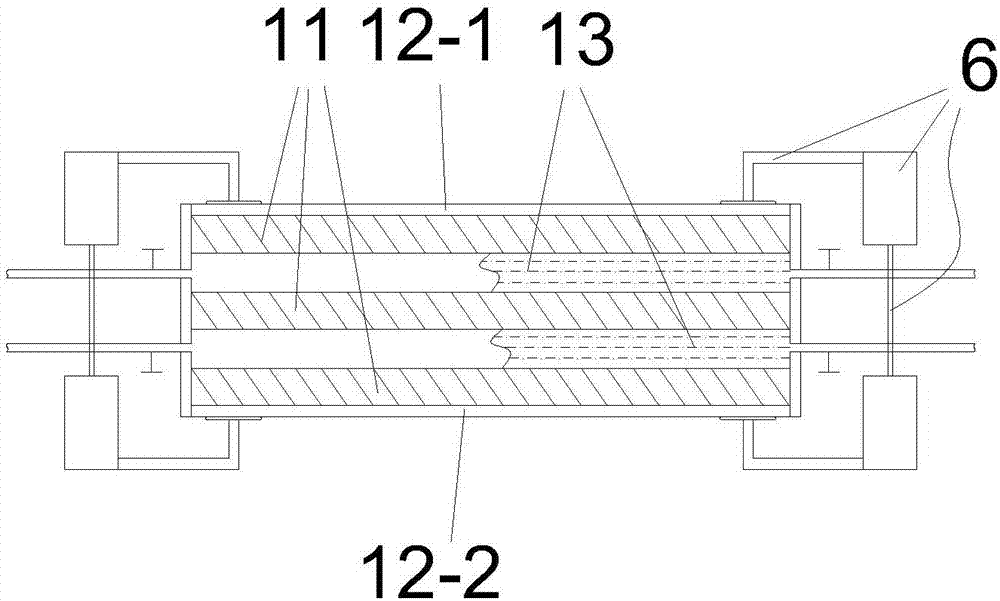

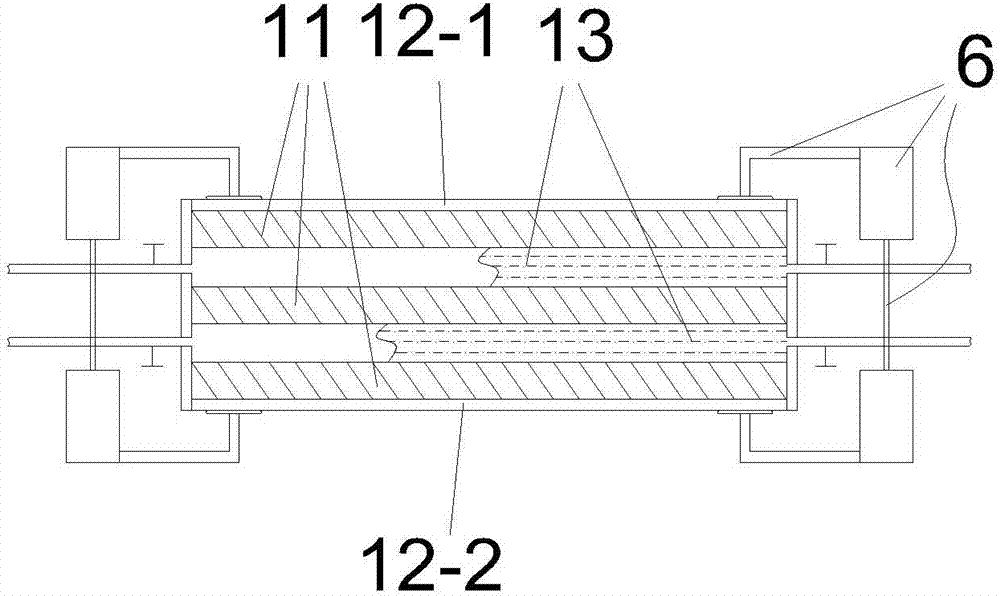

[0033] S3. Divide the rock samples into three groups. Each group of shale gas reservoir rock samples is stacked according to the upper, middle and lower layers. Board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com