Method for qualifying liquid loading of gas well

A technology for effusion and gas wells, applied in data processing applications, instruments, calculations, etc., to achieve the effects of simple testing, avoiding misjudgment, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

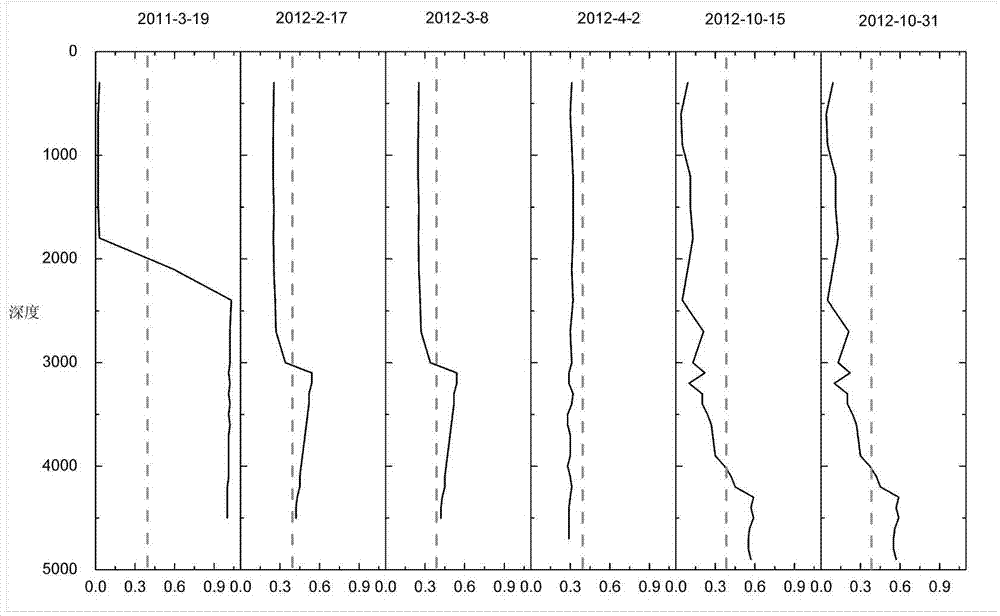

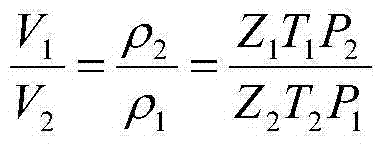

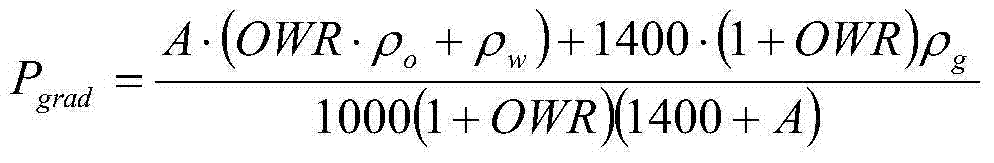

[0038] Example 1: The vertical depth from the bottom of the well to the wellhead is 5000m, the bottomhole pressure is 35MPa, the bottomhole temperature is 414.15K, and the gas deviation coefficient is 0.78; the wellhead pressure is 3.3MPa, the wellhead temperature is 284.2K, the corresponding gas deviation coefficient is 0.8965, and the gas density at the wellhead condition is 30.3745kg / m 3 , the density of condensate oil is 793kg / m 3 , the formation water density is taken as 1078kg / m 3 . Substitute the above parameters into the material balance (equation of state) model to obtain the gas density at the bottom hole condition.

[0039] Table 1

[0040]

pressure, MPa

temperature, K

Volume Variation Coefficient

Gas density, kg / m 3

known conditions

3.3

284.2

0.8965

30.3745

Bottomhole condition

35

414.15

0.78

254.0887

[0041] In Table 1, the known gas density is the gas density at the wellhead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com