Digital control system of superconducting strip material insulation wrapping device

A technology of superconducting tape and numerical control system, applied in the direction of digital control, electrical program control, electrical components, etc., can solve the problems of low thermal conductivity, unsuitable insulating tape, low wettability of polyimide epoxy resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

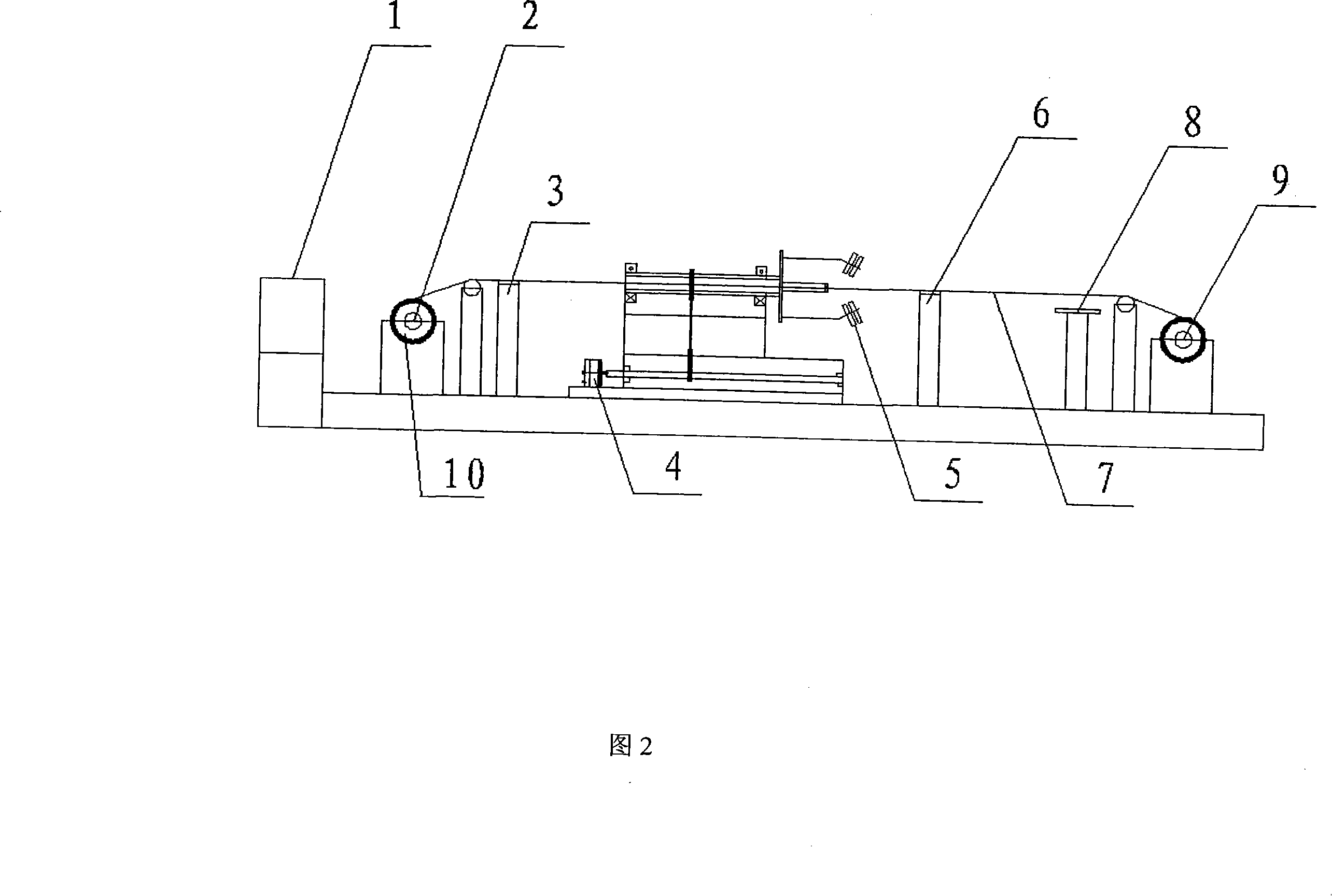

[0024] The insulation wrapping device for superconducting tape consists of two parts: mechanical device and numerical control system. As shown in Figure 2, the superconducting tape winding reel is installed on the main shaft of the torque motor 9, and the superconducting tape 7 is fixed on the winding reel on the main shaft of the AC servo motor 2 through a traction belt, controlled by the numerical control system, The insulating tape winding reel 5 rotates around the superconducting tape 7 , and the glass fiber cloth on the insulating tape winding reel 5 is wrapped on the superconducting tape 7 . Adjust the rotation speed of the insulating tape winding reel 5 of the superconducting tape insulation wrapping device and the linear displacement motion speed of the superconducting tape 7 to control the pulling force and the glass fiber cloth on the superconducting tape 7 during the wrapping process. The tension on the surface makes the up and down vibration of the superconducting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com