Method for determining bending fracture in metal plate, program, and storage medium

一种弯曲断裂、判定方法的技术,应用在使用施加稳定的弯曲力测试材料强度、仪器、电数字数据处理等方向,能够解决危险性高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings.

[0040] (basic idea)

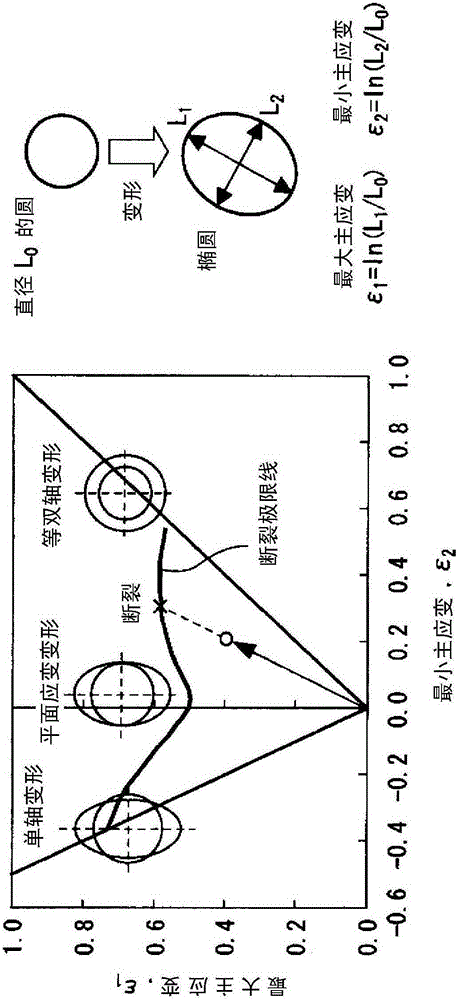

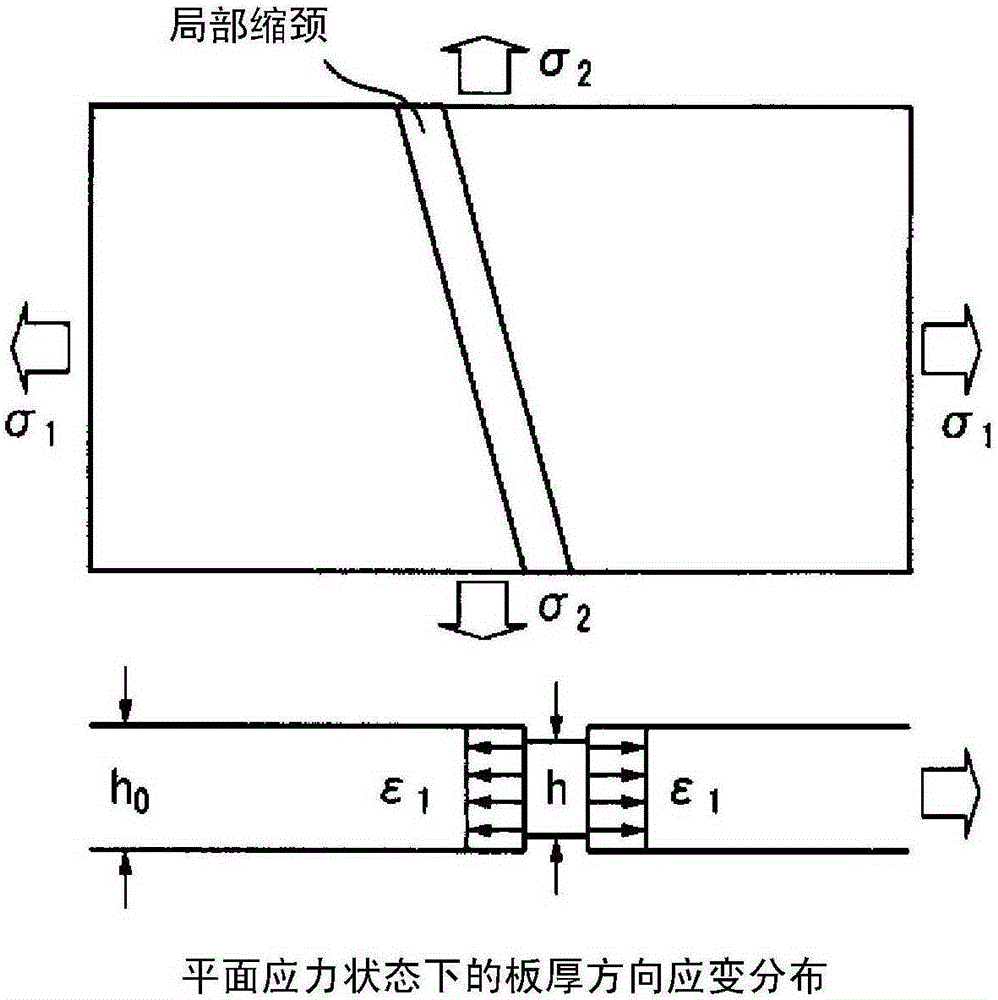

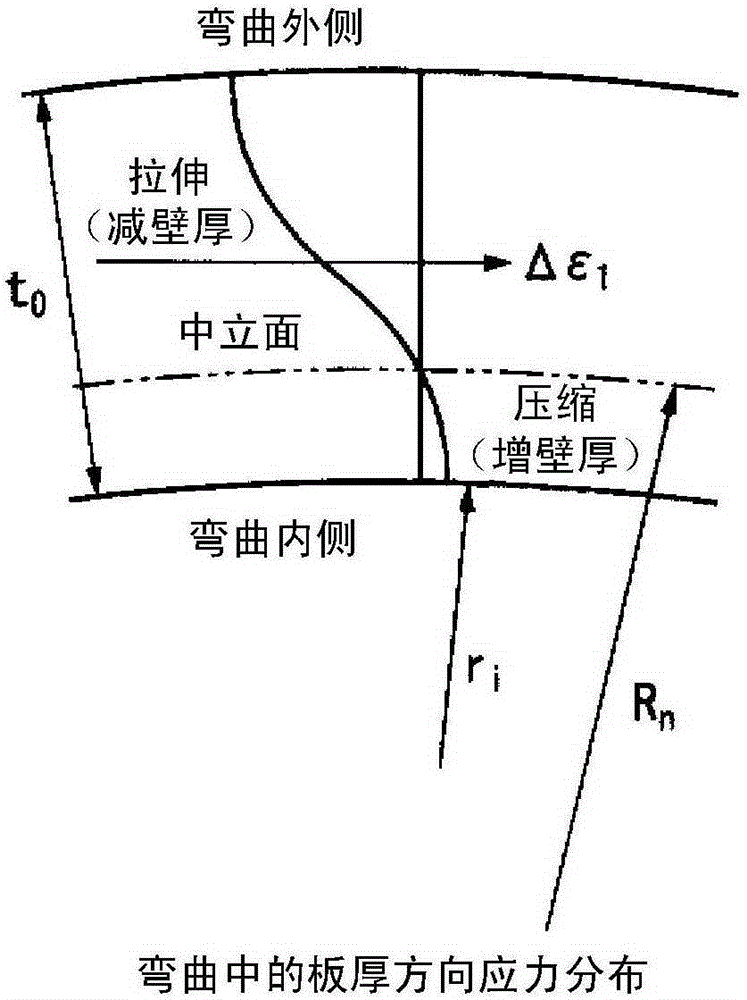

[0041] When a metal plate made of a metal material is bent and deformed, the tensile stress in the circumferential direction decreases and the compressive stress in the radial direction increases from the outside of the material to the inside of the bend, and these stresses change in magnitude and stress state as the bending progresses. However, since the stress and strain generated by bending are not distributed equally in the plate thickness direction, the local necking condition applied under the uniform distribution cannot be applied. Since the local necking condition for the same distribution cannot be applied to the fracture judgment of the curved part, the fracture judgment of the curved part based on molding simulation and impact simulation which has been widely used until now cannot obtain sufficient practical reliability.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com