Rock true triaxial pressure chamber with changeable principal stress direction when unloading

A technology of pressure chamber and principal stress, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of insufficient unloading path capacity, insufficient unloading stress path, etc., and achieve the effect of solving the insufficient unloading stress path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

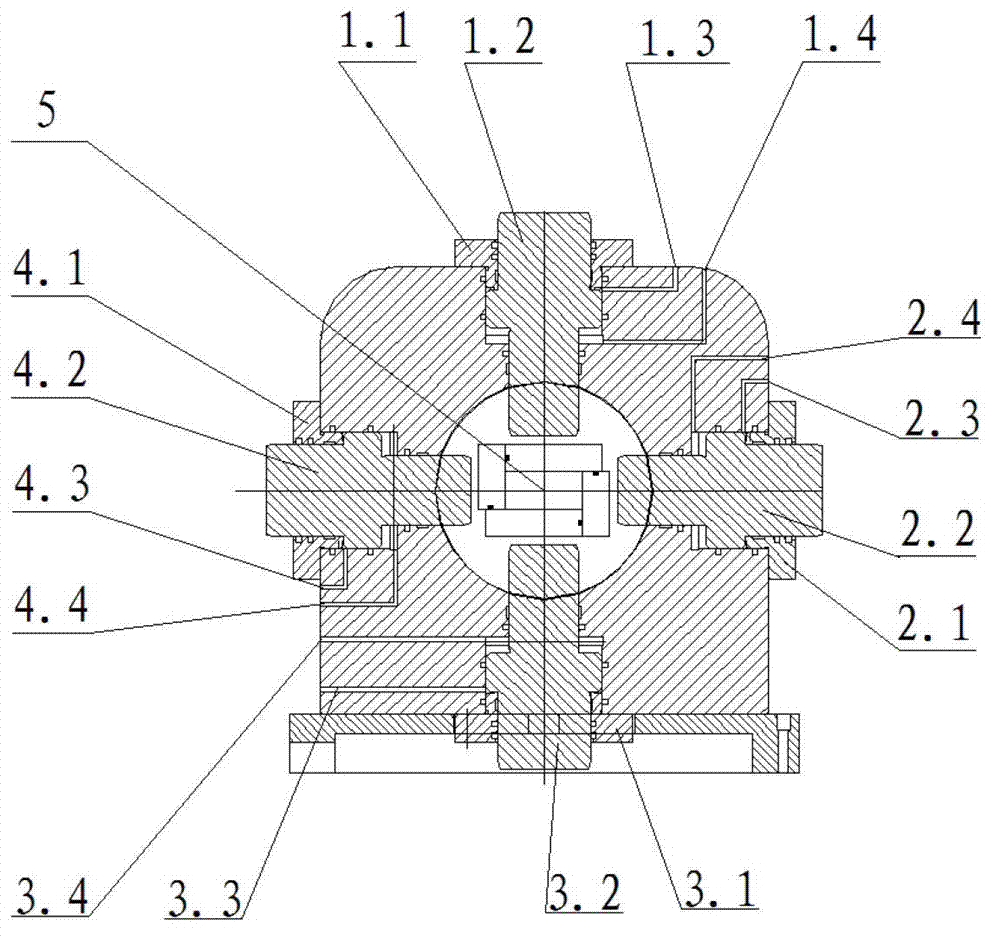

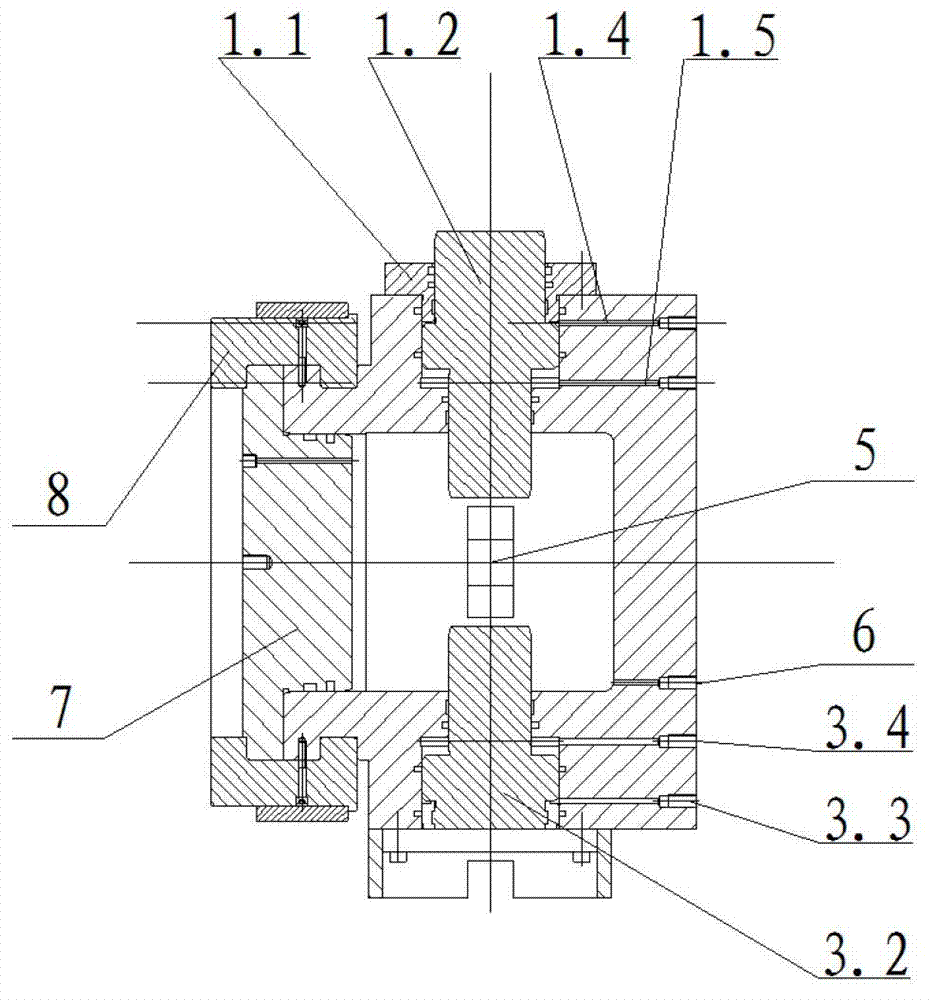

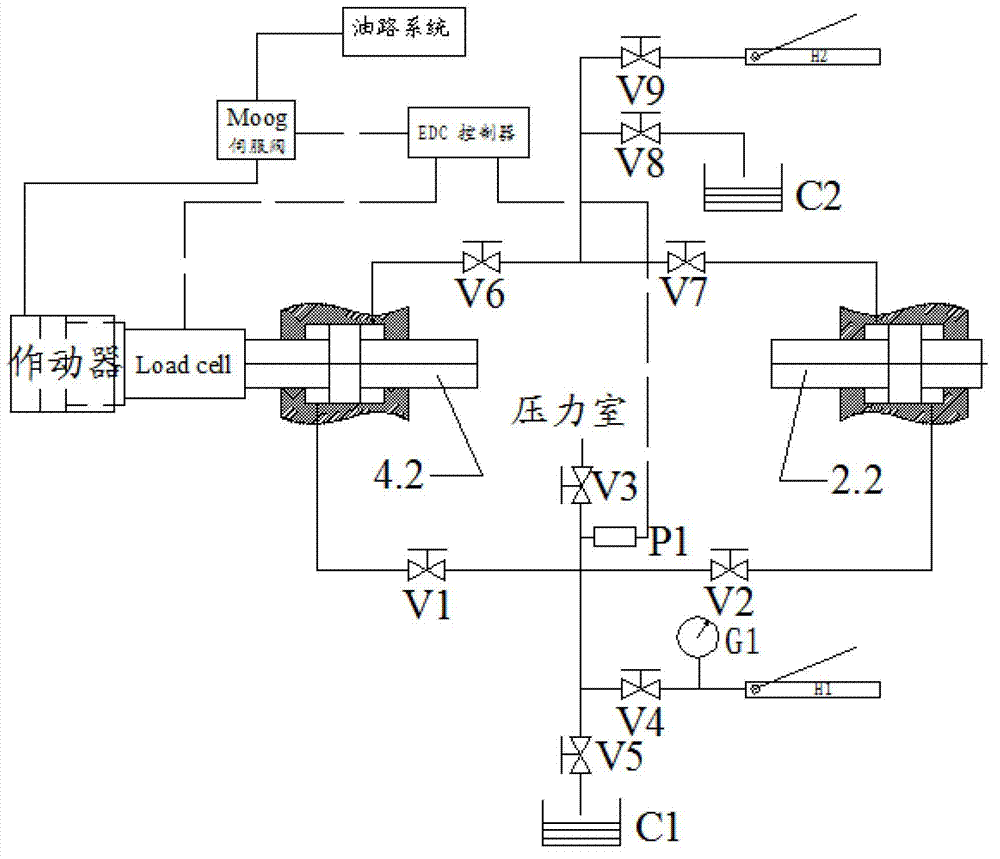

[0013] combine figure 1 and 2, the true triaxial pressure chamber of the present invention adopts a vertical structure, and the chamber size for accommodating the rock sample 5 is 50×50×100 mm. For the convenience of putting in and taking out the rock sample, a hole is opened on the front facade of the pressure chamber as the passageway for the sample, and a sealing door consisting of the pressure chamber cover 7 and the pressure chamber cover clamp 8 is installed on the hole. There is a confining pressure port 6 connected to the external oil circuit system on the rear wall of the pressure chamber. Four piston holes arranged in a cross in the plane are set in the middle part of the upper and lower chamber walls of the pressure chamber and the left and right chamber walls. The holes in the same direction are formed at one time during processing to ensure coaxiality and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com