Rock core clamp holder capable of simulating complex migration process of formation fluid and using method of rock core clamp holder

A core holder, a technology for simulating formations, applied to workpiece clamping devices, using stable tension/pressure to test material strength, scientific instruments, etc., can solve the problem of strain gauge lead and resistance grid strain gauge fracture, rock Complicated core boundary conditions, affecting the accurate measurement of strain gauges, etc., to achieve the effect of perfecting the experimental simulation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

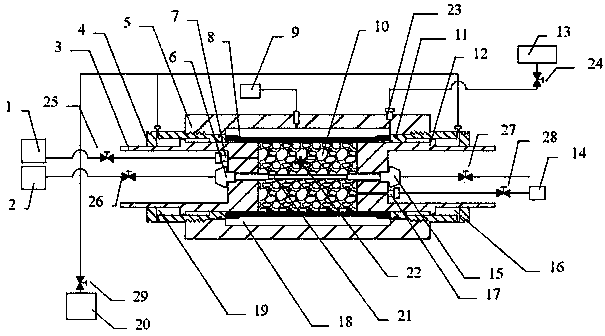

[0016] The specific embodiments of the present invention will be described with reference to the accompanying drawings.

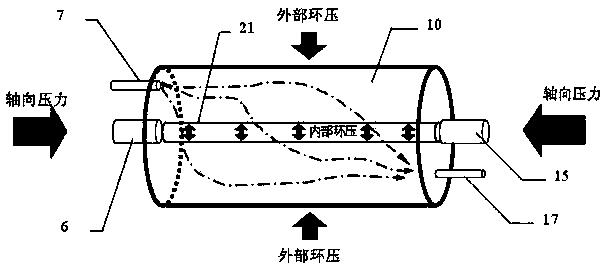

[0017] like figure 1 As shown, the three-axis core holder of the present invention is that the left end plunger sleeve 4 connects the left plunger 3 and the holder cylinder 5, and the right end plunger sleeve 11 connects the right plunger 12 and the holder cylinder 5. The left plunger 3 is nested in the left plunger sleeve 4, the right plunger 12 is nested in the right plunger sleeve 11, and there is a left axial pressure cavity 19 between the left plunger sleeve 4 and the left plunger 3 , there is a right axial pressure cavity 16 between the right end plunger sleeve 11 and the right plunger 12, the rock core 10 is wrapped in the sealing sleeve 10, its left and right ends contact the left plunger 3 and the right plunger 12 respectively, and the sealing sleeve 10 and the There is an outer ring pressure cavity 18 between the clamper cylinders 5, the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com