Intelligent optical fiber sensing skin and preparation and usage methods thereof

A smart optical fiber and sensing technology, applied in the field of sensor transmission, can solve problems such as difficult replacement and inability of optical fiber sensors to withstand harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

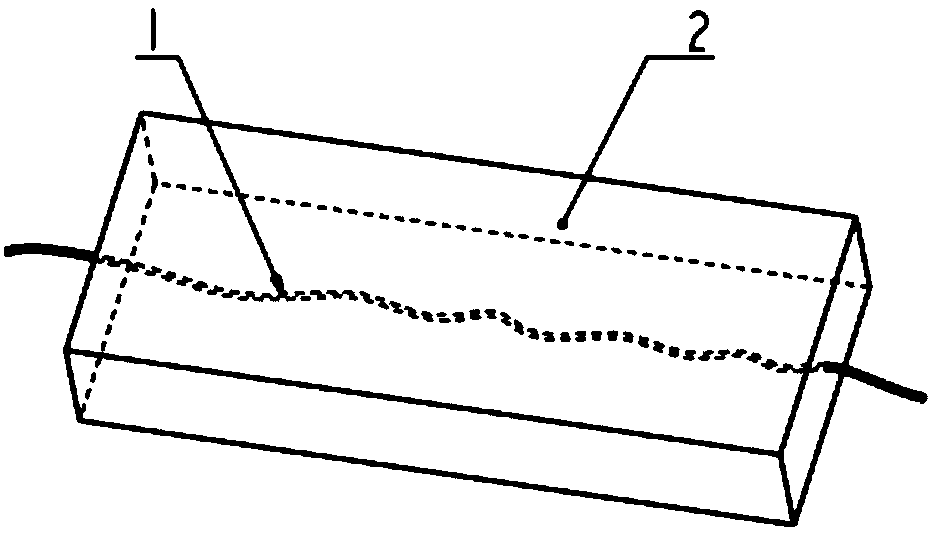

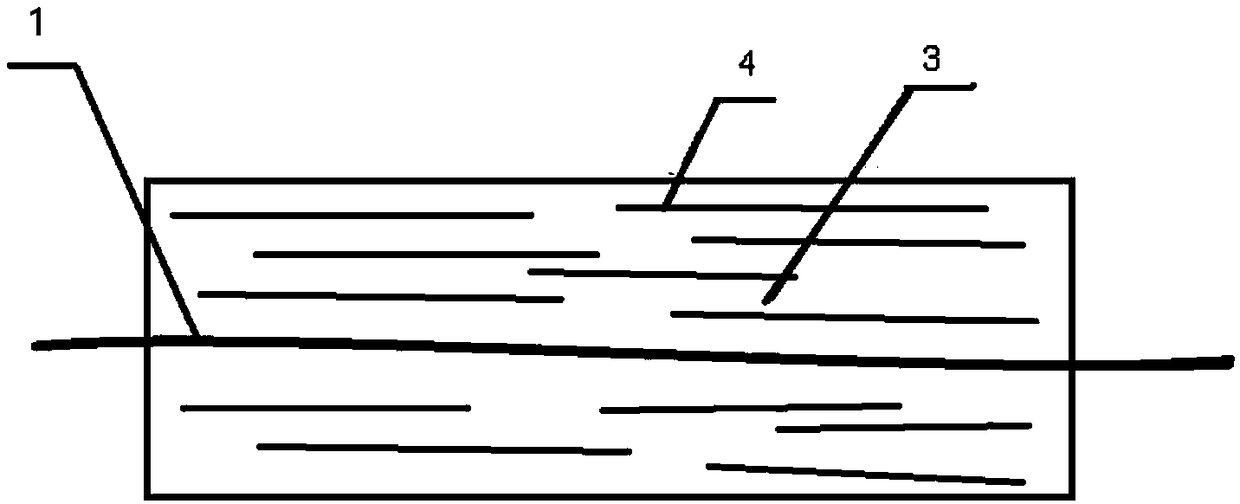

[0039] A kind of intelligent optical fiber sensing skin of the present embodiment, such as figure 1 As shown, it includes a sensing fiber 1 and a light-cured fiber-reinforced composite rubber blanket 2 , and the sensing fiber 1 is packaged inside the light-cured fiber-reinforced composite rubber blanket 2 . The light-cured fiber-reinforced composite rubber mat 2 is in the shape of a flat strip, and the base material is a light-curable resin 3. In this embodiment, it is an ultraviolet light-curable resin, and fibers 4 (or fiber mats) are filled in the light-curable resin as a reinforcing material. In 3, the fibers or fiber mats commonly used for reinforcement in the field can be used.

[0040] According to different monitoring physical quantities, the sensing optical fiber 1 can be a single-mode optical fiber or a multi-mode optical fiber. When monitoring a strain less than 20 microstrain units, a tight-packed optical fiber is used; when monitoring a strain greater than 20 micr...

Embodiment 2

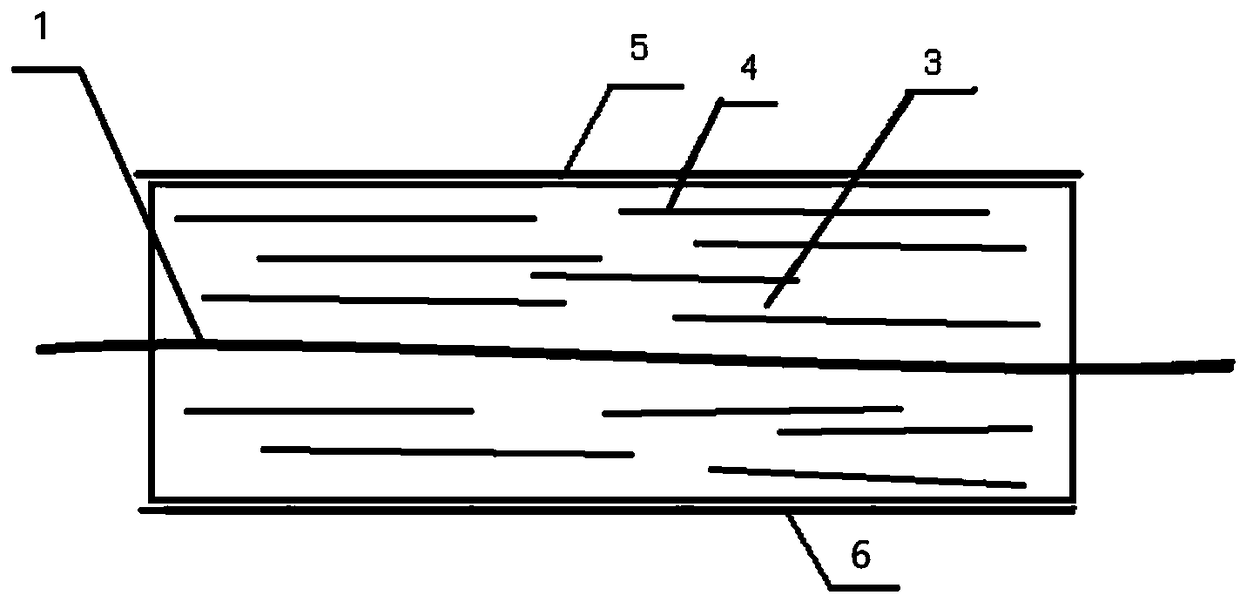

[0047] Compared with Example 1, further on the front side of the intelligent optical fiber sensing skin, that is, the side pasted with the monitored object, a layer of transparent front film 5 is set to protect and prevent sticking hands before use, and the transparent film 5 will be used during use. After tearing off the front film, paste it on the surface of the monitored object.

[0048] On the reverse side of the light-cured protective layer, that is, the side that is not pasted with the monitored object and faces the light source during use, a transparent reverse film 6 can be pasted, which can facilitate production, packaging and construction, avoid sticking hands, and do not need to be torn off during use.

Embodiment 3

[0050] The difference from Example 2 is that the opaque reverse film 6 is pasted on the reverse side of the light-cured protective layer, which can further prolong the construction time and avoid curing in advance due to sunlight irradiation before the complete finalization. If rapid curing is required, light-cured Then the opaque light-shielding reverse film 6 should be torn off in time before.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com