Batch production method for carving-customized type ceramic

A production method and batch technology, applied in the field of mass production of carved custom ceramics, can solve the problems of high cost and low production efficiency, and achieve the effects of low production cost, high production efficiency and rapid carving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

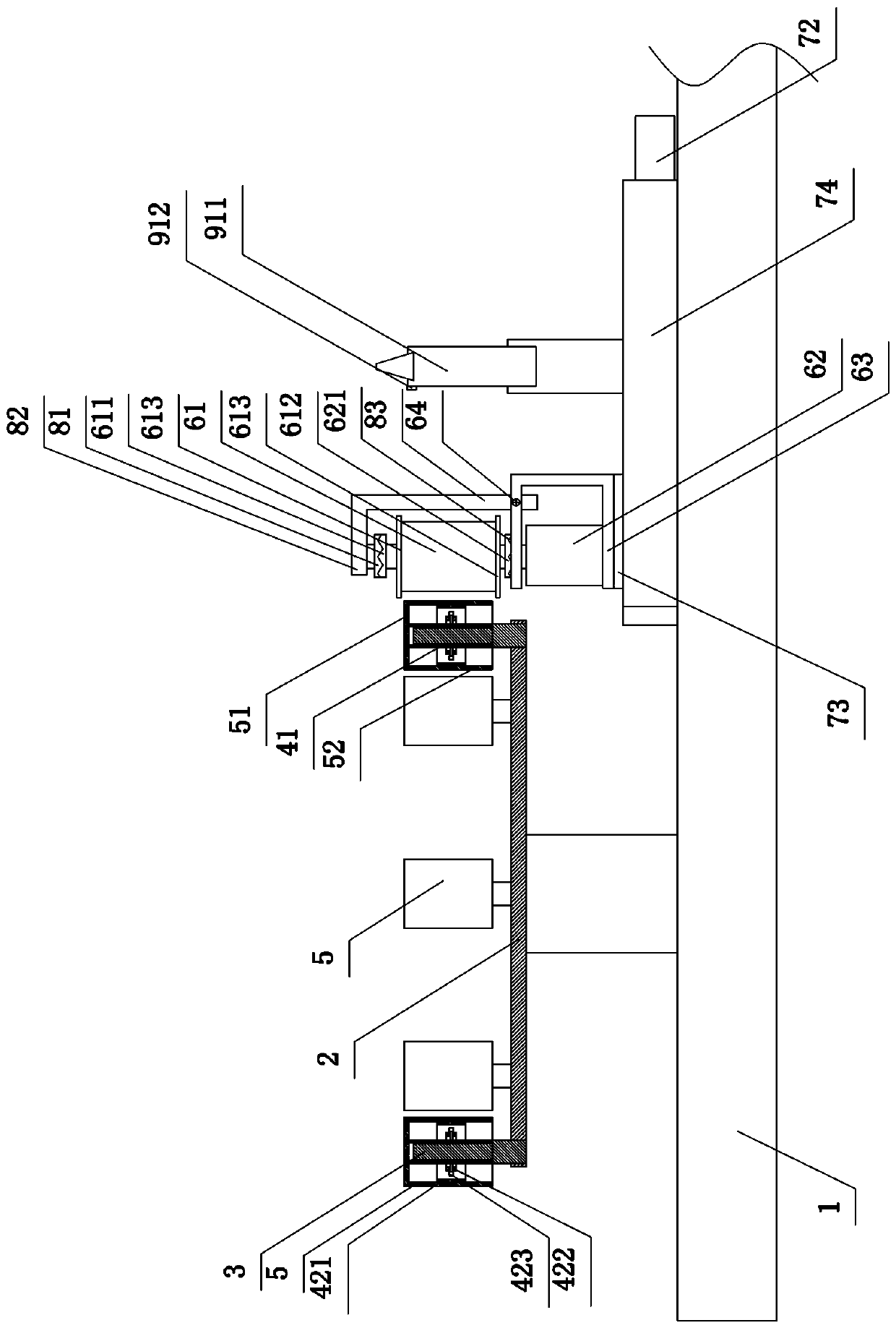

[0033] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

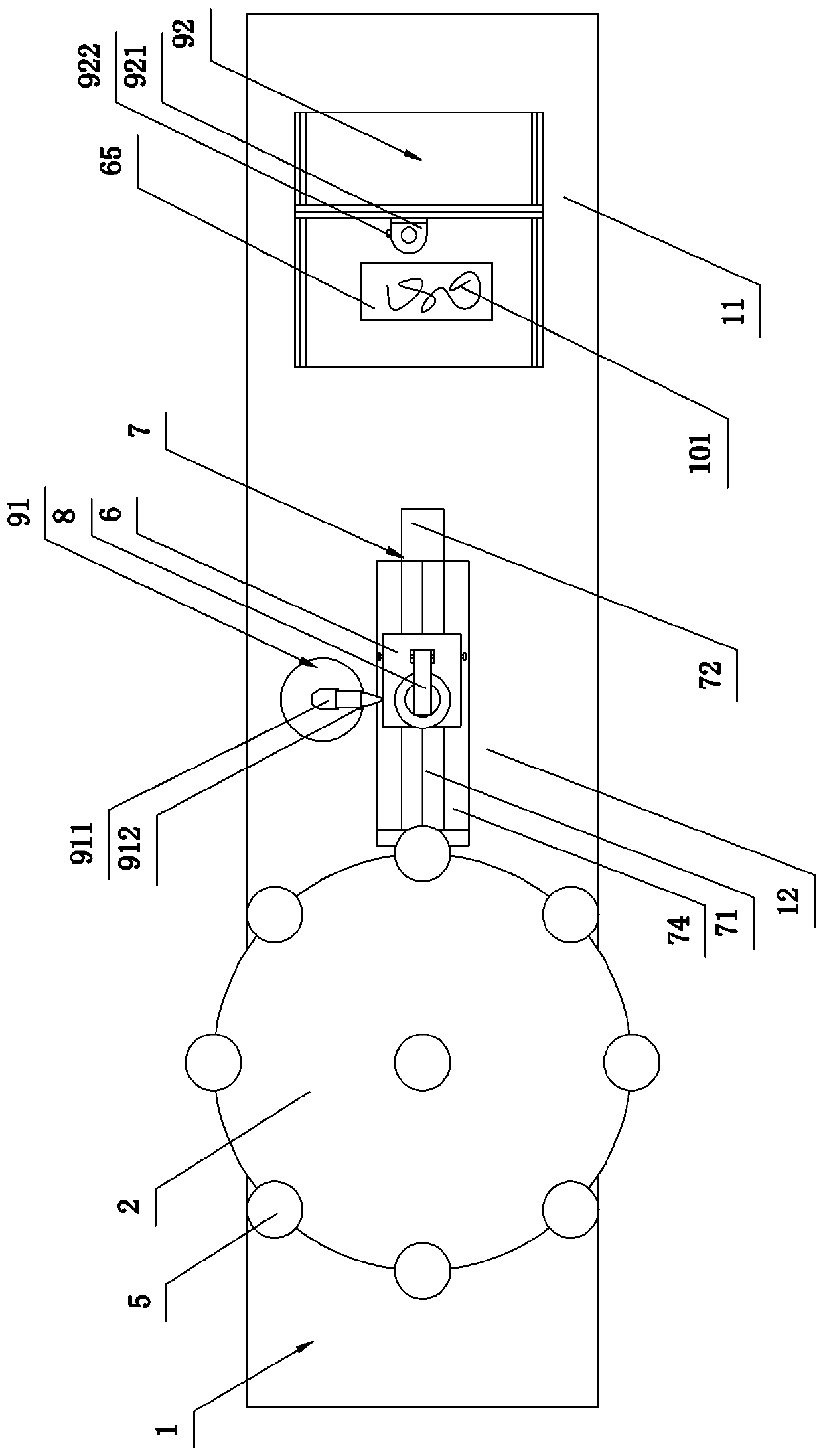

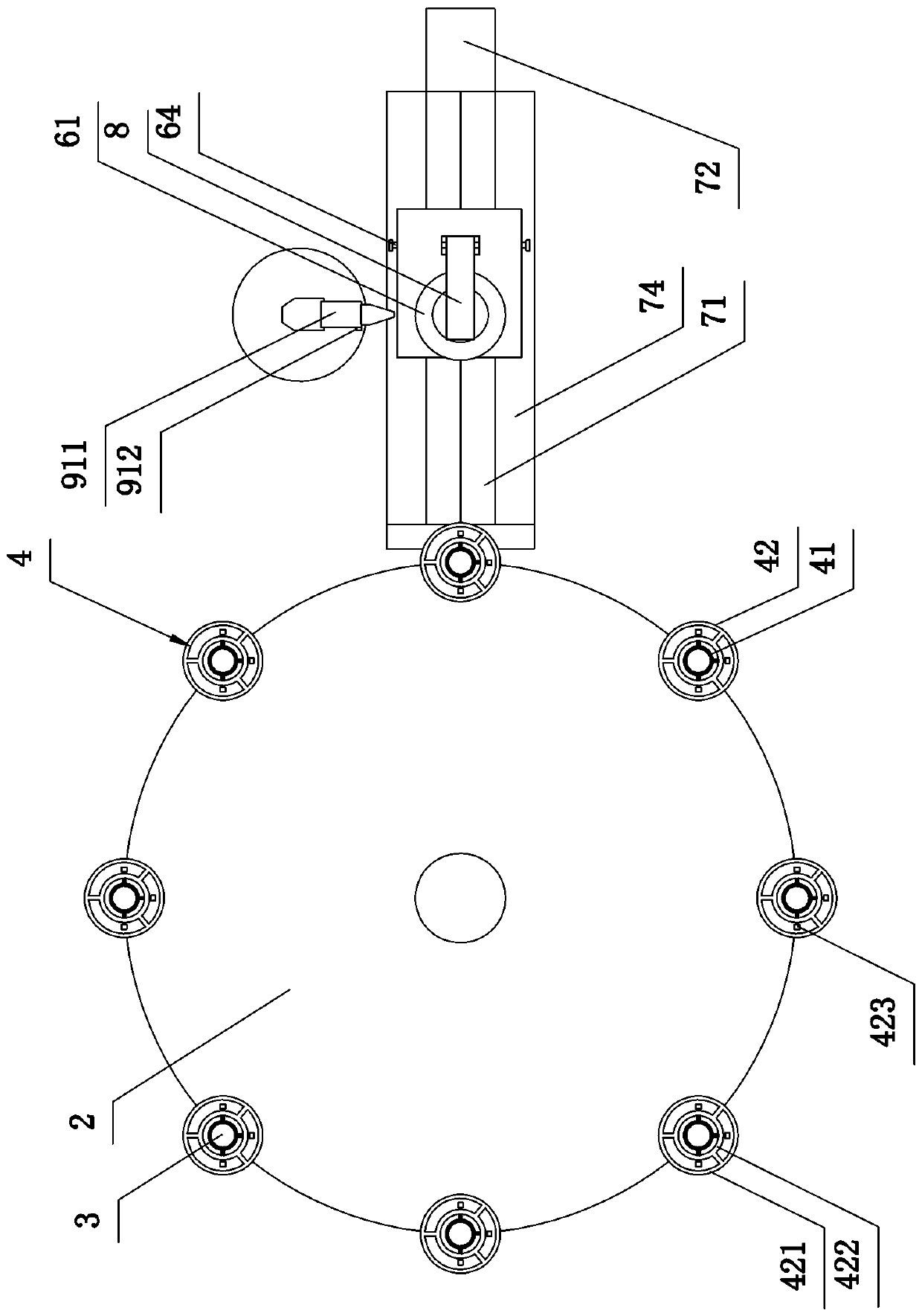

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 . A batch production method of carved custom-made ceramics, comprising the following steps:

[0035] 1) Receive the user's order, which contains the carved pattern designed by the user;

[0036] 2) Upload the order information to the visual 3D printing device 92; meanwhile place the flexible printing belt 65 on the printing platform 11;

[0037] 3) The visual 3D printing device 92 recognizes the engraved pattern in the order information, and automatically prints the engraved pattern 101 identical to the engraved pattern on the front of the printing belt;

[0038] 4) transfer the printed printing belt 65 to the engraving platform 12, and install the stamp 61 on the rotary engraving mechanism 6; the printing belt 65 can be transported to the engraving platform 12 by manual handli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com