Double-component water-soluble spraying glue and preparation method of double-component water-soluble spraying glue

A water-soluble, two-component technology, used in applications, inks, coatings, etc., can solve the problems of restricting the promotion and application of water-based spray glue, and achieve the effect of improving work efficiency, improving strength and viscosity, and increasing bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

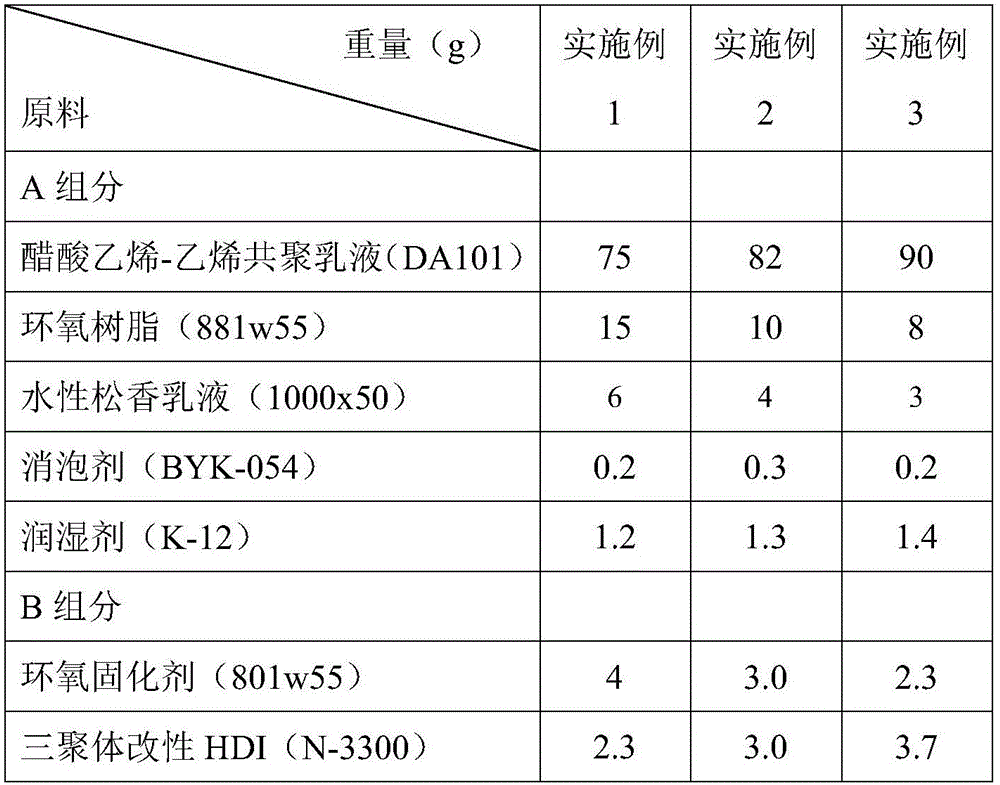

[0032] A preparation method of two-component water-soluble spray glue, comprising the following steps:

[0033] 1) Under the condition of a stirring speed of 400r / min, weigh 75g of vinyl acetate-ethylene copolymer emulsion and 15g of epoxy resin, add them to a reaction vessel in turn, stir for 3min, and mix well; increase the stirring speed to 520r / min , weighed 6g of water-based rosin emulsion, 1.2g of wetting agent and 0.2g of defoamer and added them to the reaction vessel in turn, stirred for 3min, mixed evenly and discharged to obtain component A;

[0034] 2) Under the condition that the stirring speed is 520r / min, weigh 4g of epoxy curing agent and 2.3g of hexamethylene diisocyanate trimer (that is, trimer modified HDI) into another reaction vessel, stir for 3min, Discharge after mixing evenly to obtain component B.

[0035] 3) Under the condition of stirring speed of 520r / min, slowly pour B component into A component, and continue to stir for 5 minutes to obtain a two-c...

Embodiment 2

[0037] A preparation method of two-component water-soluble spray glue, comprising the following steps:

[0038] 1) Under the condition of a stirring speed of 410r / min, weigh 82g of vinyl acetate-ethylene copolymer emulsion and 10g of epoxy resin, add them to a reaction vessel in turn, stir for 3min, and mix well; increase the stirring speed to 550r / min , weigh 4g of water-based rosin emulsion, 1.3g of wetting agent and 0.3g of antifoaming agent and add them to the reaction vessel in turn, stir for 3min, mix and discharge the material evenly to obtain component A;

[0039] 2) Under the condition of stirring speed of 550r / min, weigh 3.0g of epoxy curing agent and 3.0g of trimer modified HDI and add them into another reaction vessel, stir for 3min, mix evenly and discharge to obtain group B point.

[0040] 3) Under the condition of stirring speed of 550r / min, slowly pour B component into A component, and continue stirring for 4 minutes to obtain a two-component water-soluble spr...

Embodiment 3

[0042] A preparation method of two-component water-soluble spray glue, comprising the following steps:

[0043] 1) Under the condition of a stirring speed of 450r / min, weigh 90g of vinyl acetate-ethylene copolymer emulsion and 8g of epoxy resin, add them to a reaction vessel in turn, stir for 3min, and mix well; increase the stirring speed to 550r / min , weighed 3g of water-based rosin emulsion, 1.4g of wetting agent and 0.2g of defoamer and added them to the reaction vessel in sequence, stirred for 3min, mixed evenly and discharged to obtain component A;

[0044] 2) Under the condition of a stirring speed of 550r / min, weigh 2.3g of epoxy curing agent and 3.7g of trimer modified HDI and add them into another reaction vessel, stir for 3min, mix evenly and discharge to obtain group B point.

[0045] 3) Under the condition of a stirring speed of 550r / min, slowly pour the B component into the A component, and continue to stir for 5 minutes to obtain a two-component water-soluble s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com