Melamine resin and polyurea resin double-shell microcapsule and preparing method and application thereof

A technology of polyurea resin and melamine resin, which is applied in the field of melamine resin and polyurea resin double-shell microcapsules and their preparation, can solve the problems that the application range is greatly affected by environmental temperature and humidity, and the storage of core materials is unstable. , to achieve sustained and stable slow-release effect, increased storage stability, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

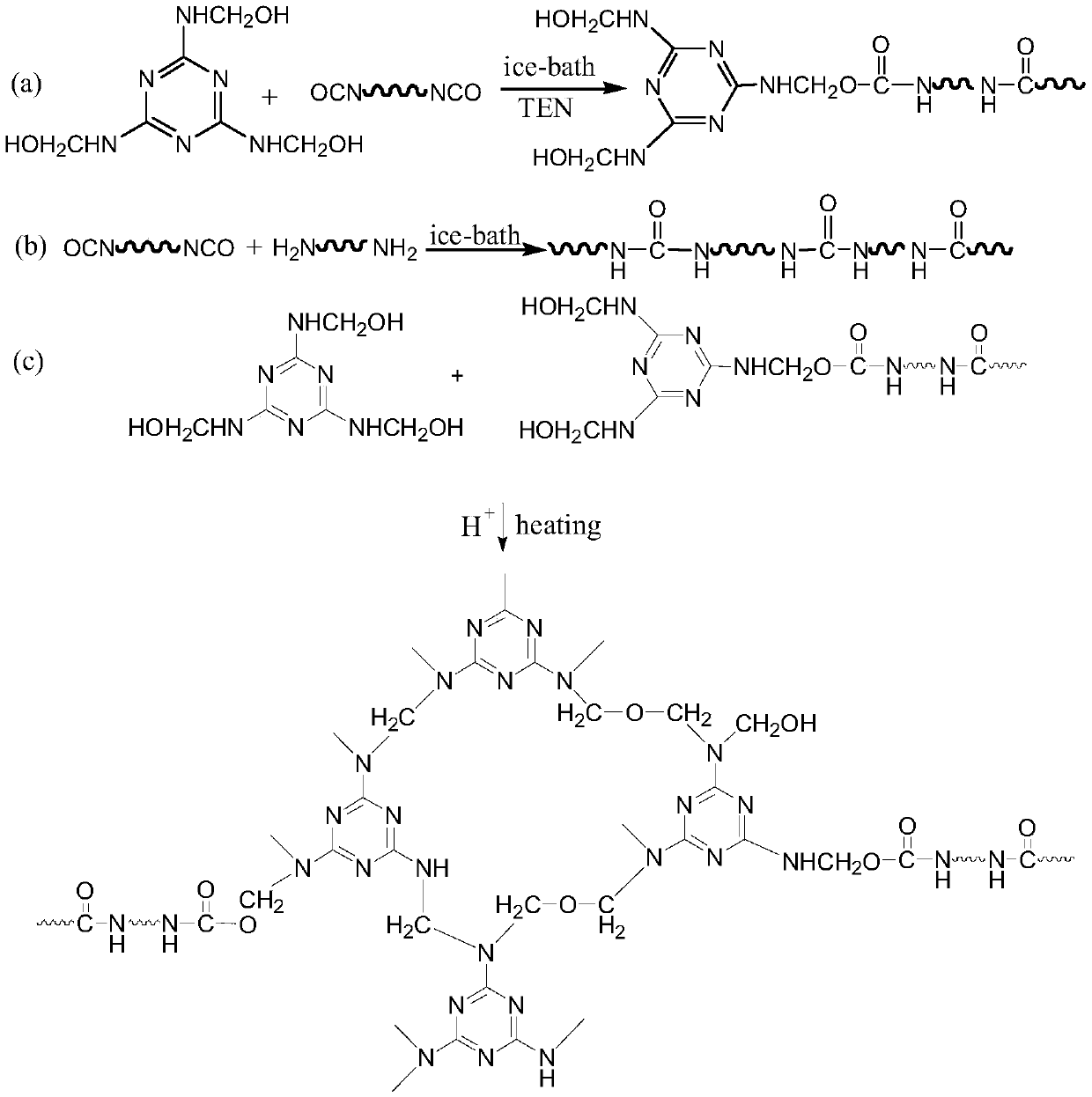

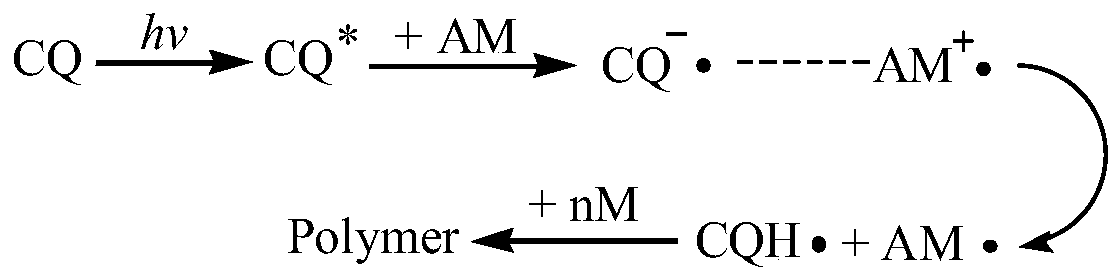

Method used

Image

Examples

Embodiment 1

[0048] The prepared melamine resin and polyurea resin double-shell microcapsules are used in visible light self-healing materials, and the raw material formula is shown in Table 1.

[0049] Table 1

[0050]

[0051]

[0052] (1) Preparation of melamine prepolymer: Weigh melamine and formaldehyde solution according to the formula, (add melamine first and then add formaldehyde) in a three-necked flask and stir and mix, add triethylamine to adjust the pH value of the system to 8-9, mix melamine Heat and stir the mixed solution with formaldehyde in a 65°C water bath. After about 10 minutes, the system becomes transparent. Add distilled water of the same quality as the formaldehyde solution and continue the reaction for 50 minutes to obtain a transparent low molecular weight water-soluble melamine-formaldehyde prepolymer (melamine prepolymer).

[0053] (2) Preparation of melamine resin and polyurea resin double-shell microcapsules: take by weighing emulsifier gum arabic powd...

Embodiment 2

[0059] The prepared melamine resin and polyurea resin double-shell microcapsules are used in visible light self-healing materials, and the raw material formula is shown in Table 2.

[0060] Table 2

[0061]

[0062] (1) The preparation process of melamine prepolymer: take melamine and formaldehyde solution according to the formula, (add melamine first and then add formaldehyde) in a three-necked flask and stir and mix, add an appropriate amount of triethylamine to adjust the pH value of the system to 8-9, Heat and stir the mixed solution of melamine and formaldehyde in a water bath at 65°C. After about 10 minutes, the system becomes transparent. Add distilled water of the same quality as the formaldehyde solution and continue the reaction for 50 minutes to obtain a transparent low molecular weight water-soluble melamine-formaldehyde prepolymer.

[0063] (2) The preparation process of melamine resin and polyurea resin double-shell microcapsules: take emulsifier gum arabic po...

Embodiment 3

[0067] The prepared melamine resin and polyurea resin double-shell microcapsules are used in visible light self-healing materials, and the raw material formula is shown in Table 3.

[0068] table 3

[0069]

[0070] (1) The preparation process of melamine prepolymer: take melamine and formaldehyde solution according to the formula, (add melamine first and then add formaldehyde) in a three-necked flask and stir and mix, add an appropriate amount of triethylamine to adjust the pH value of the system to 8-9, Heat and stir the mixed solution of melamine and formaldehyde in a water bath at 65°C. After about 10 minutes, the system becomes transparent. Add distilled water of the same quality as the formaldehyde solution and continue the reaction for 50 minutes to obtain a transparent low molecular weight water-soluble melamine-formaldehyde prepolymer.

[0071] (2) The preparation process of melamine resin and polyurea resin double-shell microcapsules: take emulsifier gum arabic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com