Method for measuring bond strength of aggregate in superfine and nanometer tungsten carbide powder

A nano-tungsten carbide, bonding strength technology, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of complex test process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

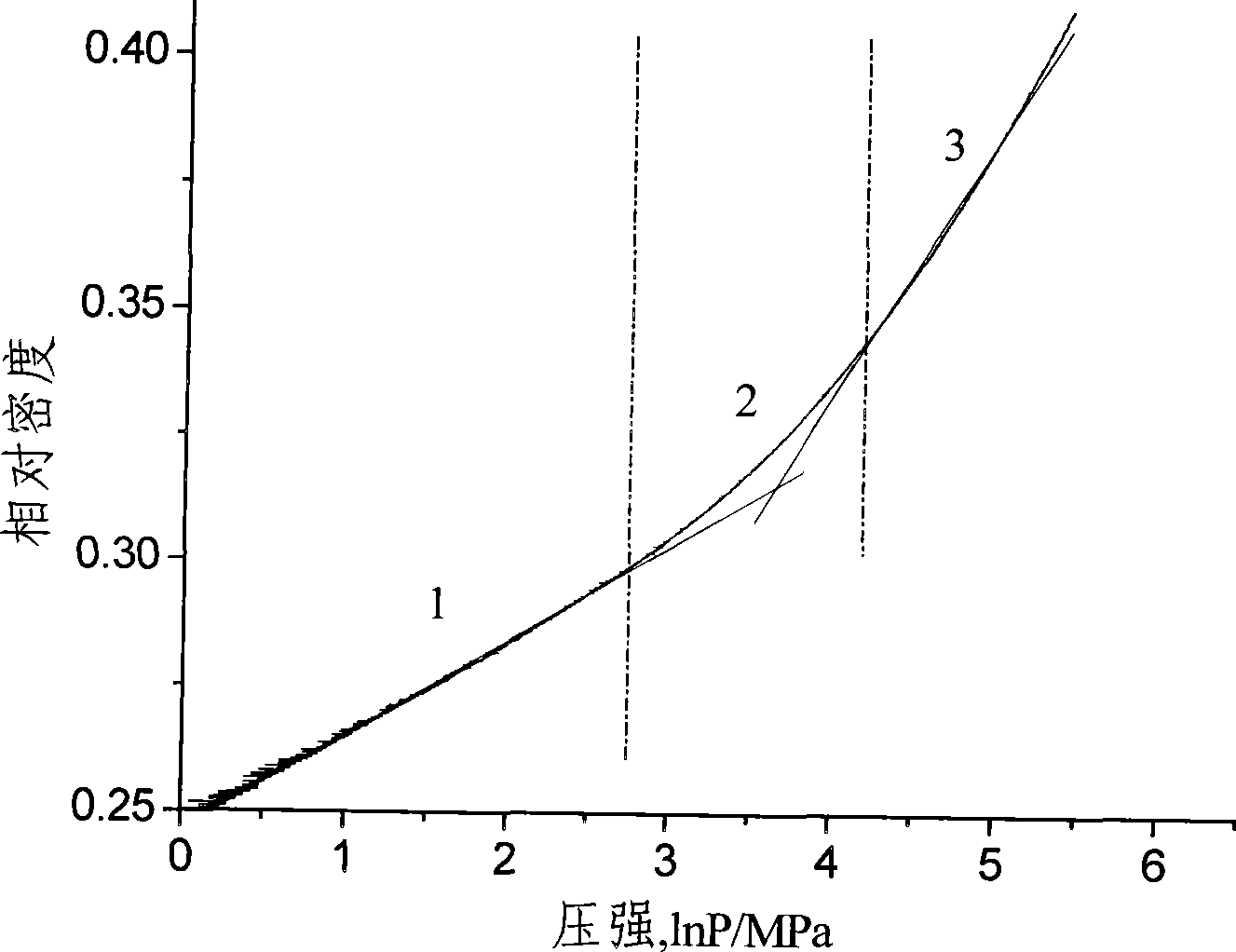

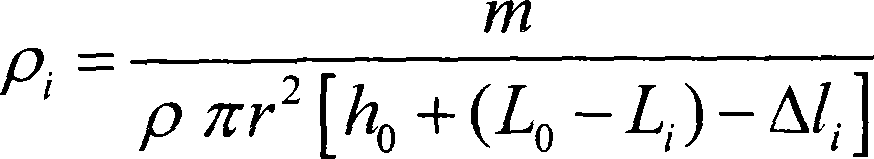

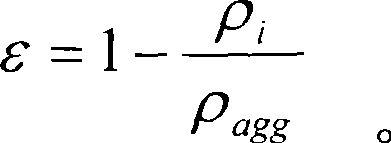

Method used

Image

Examples

Embodiment Construction

[0030] Raw material: tungsten carbide powder with an average particle size of 100nm.

[0031] Testing process:

[0032] (1) Weigh 2.5g of the above-mentioned tungsten carbide powder on a tray electronic balance, put it into a steel mold with a diameter of 10mm, and use the one-way compression method to continuously compress the powder on the CMT5000 universal mechanical testing machine. 0.5mm / s.

[0033] (2) After being pressed and formed under 300MPa pressure, carefully demould to obtain a green body with complete shape. The mass of the green body was weighed on an electronic balance to be 2.30 g, and the final height of the green body was measured to be 4.500 mm with a micrometer.

[0034] (3) After taking out the powder, put the mold on the universal mechanical testing machine, and use one-way or two-way method to continuously compress the mold, and the computer automatically records the elastic deformation of the mold and the beam under a certain pressure.

[0035] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com