Auxiliary water supply electric pump in nuclear power plant

An auxiliary water supply and electric pump technology, applied in the field of machinery, can solve the problems of insufficiency of thermal shock, inconvenient maintenance, poor shock resistance, etc., and achieve the effect of improving shock resistance, convenient maintenance and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

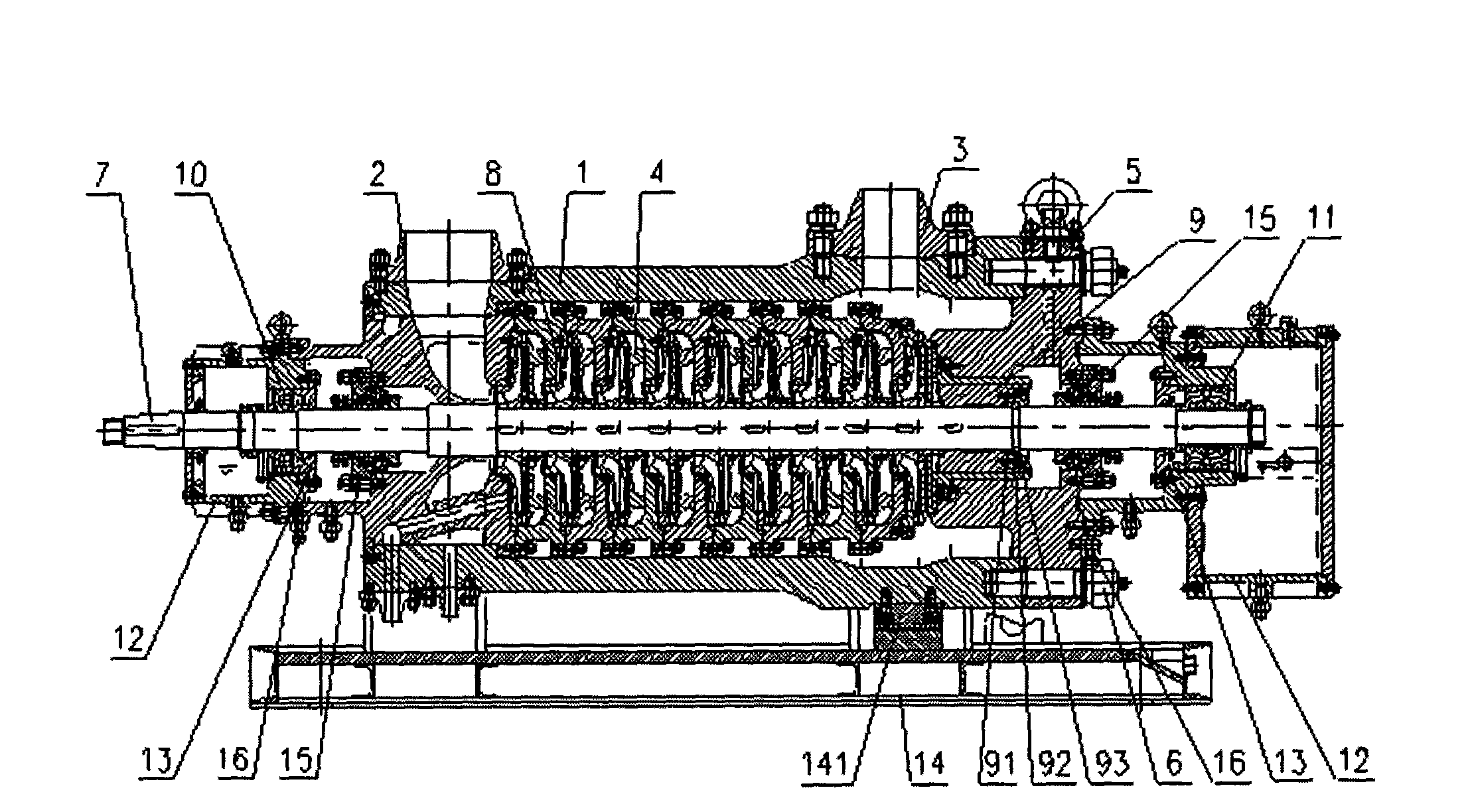

[0014] Such as figure 1 As shown, the structure of the nuclear power plant auxiliary feed water electric pump of the present invention is a horizontal multistage centrifugal pump with double casings and a segmented inner casing. The multistage centrifugal pump is a horizontal structure and has a cylindrical shape A core-pulling pump body 1, the cylindrical pump body 1 is provided with a segmented inner casing that can be drawn out as a whole, and the multistage centrifugal pump is provided with a stator assembly, a rotor assembly, a bearing Assembly and shaft seal assembly, wherein, the lower part of the pump body 1 is provided with a pump foot guide key 141, the stator assembly is fixed on the pump body 1, the suction port 2 and the discharge port 3 of the pump body 1 are perpendicular to The axis of the pump body 1, the suction port 2 is set at one end of the pump body 1, the discharge port 3 is set at the other end of the pump body 1, the stator assembly is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com