Assembly-type section steel cantilever protective shed

A protective shed and prefabricated technology, which is applied in the direction of housing structure support, housing structure support, and scaffolding supported by housing structure, etc., can solve the problems of low safety performance, easy-to-pull end of wire rope, low safety performance of single-layer structure protective layer, etc. , to achieve the effect of many times of turnover, improving bearing capacity and impact strength, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments.

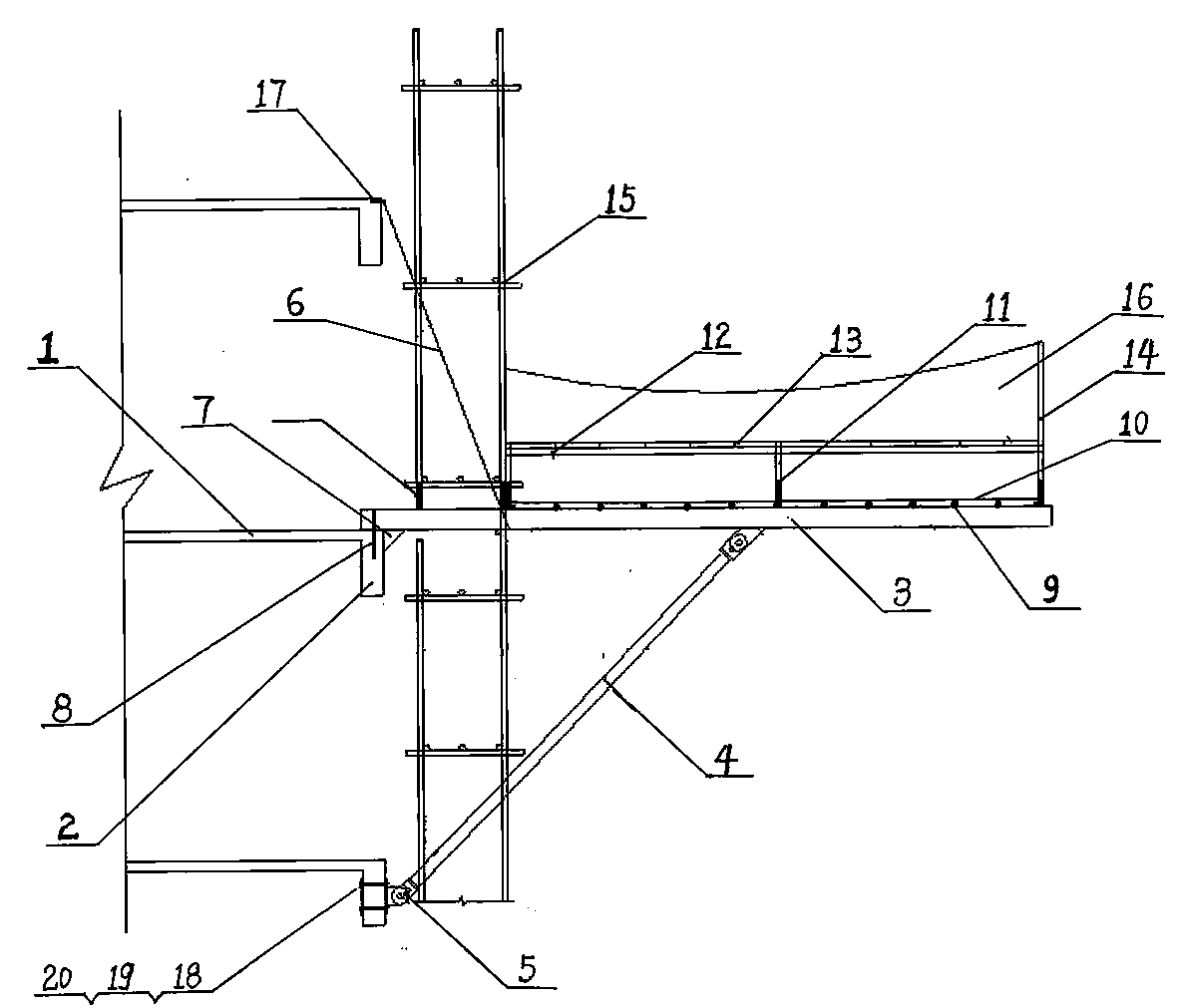

[0019] In the picture: a prefabricated steel cantilever protection shed includes I-beam main beam 3, diagonal bracing channel steel 4, hinged member 5, diagonal-stayed steel wire rope 6, triangular bracing angle 7, embedded ring 8, steel bar beam 9, steel plate 10. Support steel pipe 11, main steel pipe 12, scaffold plate 13, skeleton steel pipe 14, scaffold 15, protective net 16, embedded parts 17, PVC casing 18, steel backing plate 19 and screw 20. Two or more I-beam main beams 3 are arranged parallel to the building floor 1. One end of the I-beam main beam is supported on the main structural beam of any building floor, and the other end of the I-beam main beam extends out of any of the above-mentioned building floors. Multiple steel beams 9 are vertically connected between two I-beam main beams, and steel plates 10 are laid on the multiple steel beams; the I-beam ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com