Large-tonnage lorry-mounted crane

A truck-mounted crane and large tonnage technology, applied in cranes and other directions, can solve the problems of poor suitability of the chassis with different passability of the whole machine, inability to meet the needs of large-scale work, and few telescopic boom sections, etc. Simple structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

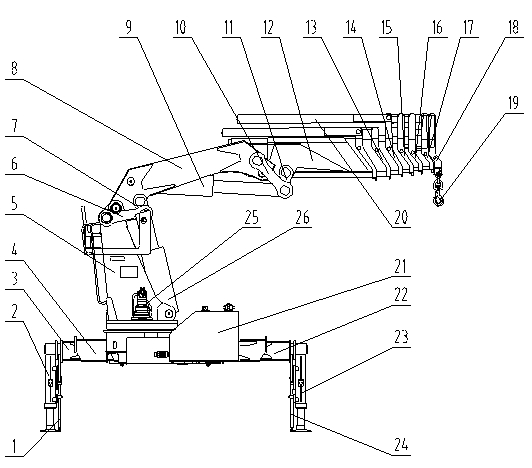

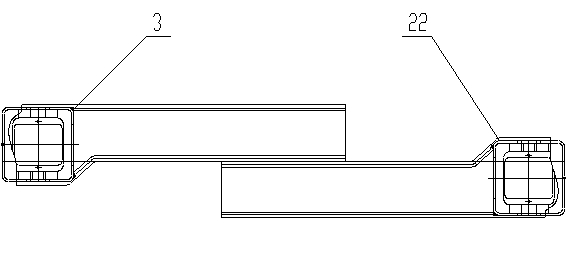

[0012] As shown in the accompanying drawings, the truck-mounted crane of the present invention is mainly composed of a leg assembly, a slewing mechanism, a first luffing mechanism, a second luffing mechanism, a telescopic arm assembly and a suspension hook 19 . Wherein: the outrigger assembly includes two vertical telescopic outriggers, two horizontal telescopic outriggers, two turning slides and a base 4 . The base 4 is connected to the chassis of the car through a "U"-shaped bolt; the horizontal outriggers I and II are two-stage horizontal telescopic outriggers, and the expansion and contraction of the two-stage outriggers is realized through the oil cylinder and cable mechanism, which is different from the general single Compared with the first-class horizontal telescopic outriggers, the span between the horizontal outriggers is effectively increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com