Main shaft universal bracket for engraving and milling machine

A universal bracket, engraving and milling machine technology, applied in the direction of support, metal processing mechanical parts, clamping and other directions, can solve the problems of inability to move each other, short use range, wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

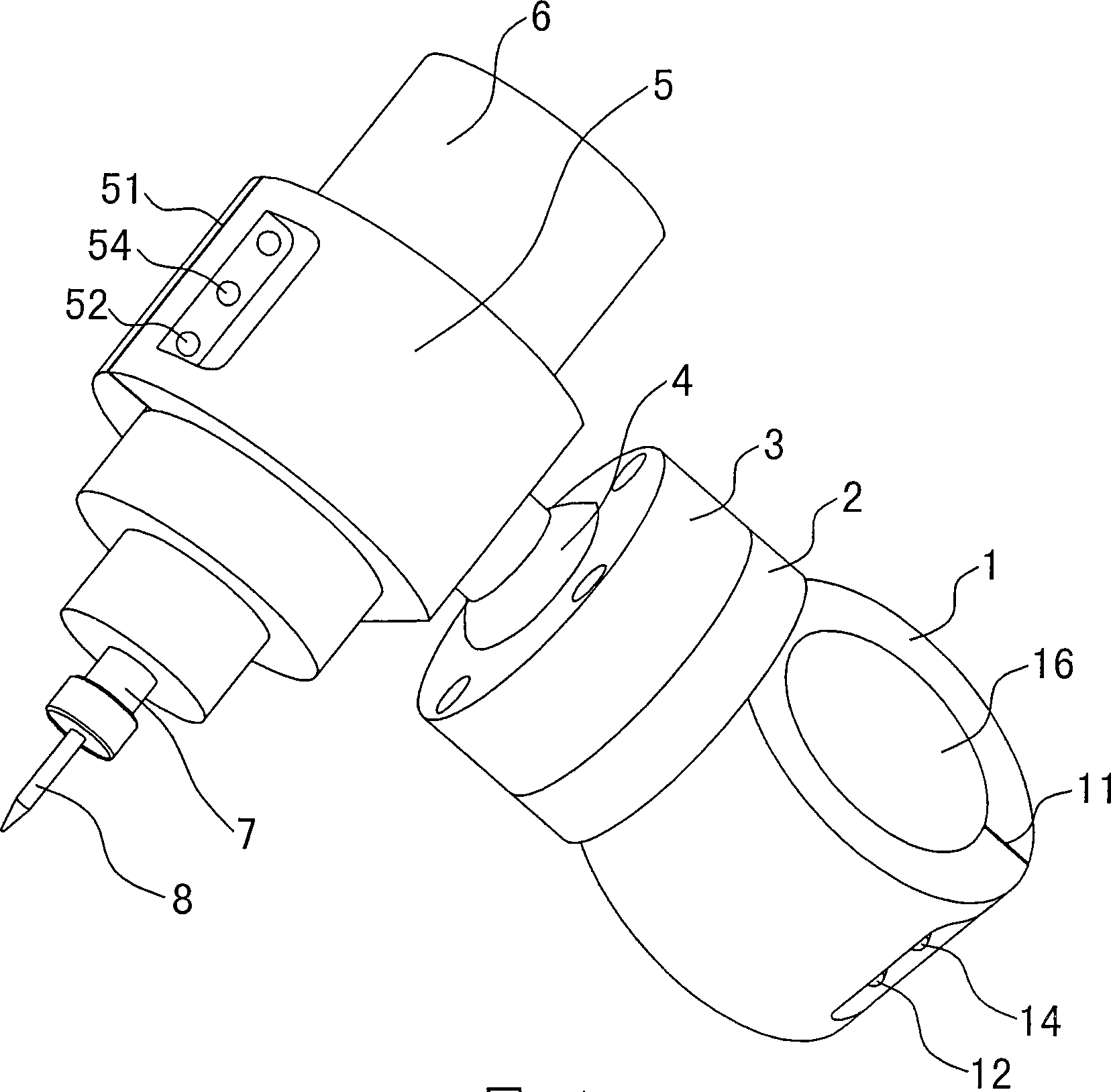

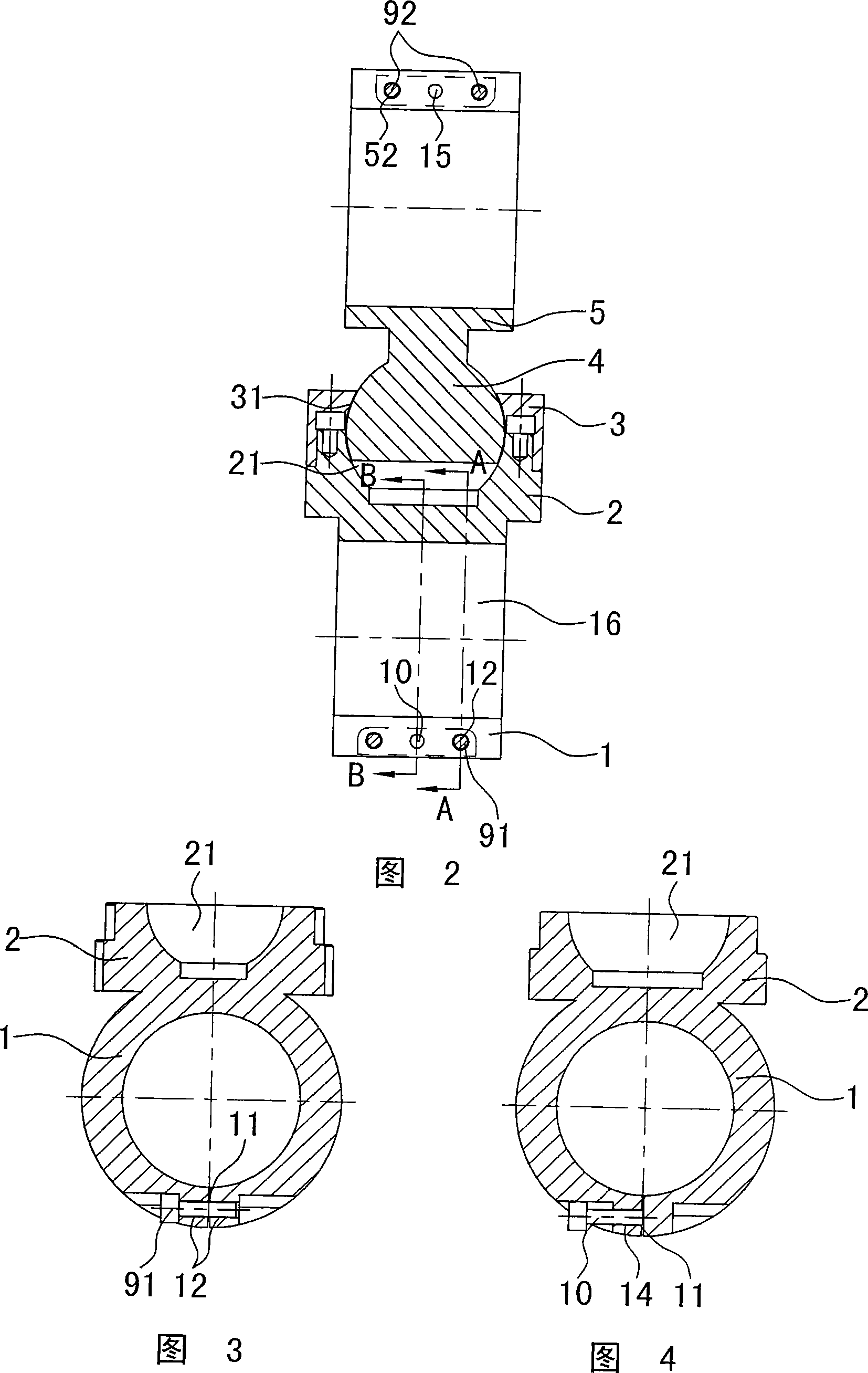

[0011] The invention discloses a universal support for the main shaft of an engraving and milling machine, such as figure 1 , figure 2 As shown, it is characterized in that it includes a fixed sleeve 1 that is movably installed on the head of the engraving and milling machine (the fixed sleeve is formed with a shaft hole 16, and the main shaft passes through the shaft hole of the fixed sleeve), the fixed sleeve is connected to the ball joint body 2, and the ball joint body Fasten the ball joint gland 3, the ball joint gland 3 and the ball joint body 2 are formed with ball sockets 31, 21, the ball sockets 31, 21 are equipped with universal ball joints 4, and the universal ball joints 4 move through the chuck 5 Install the motor 6, the motor shaft 7 is connected to the tool 8, the fixed sleeve 1 and the machine head are movable installation, there are many ways to install the fixed sleeve and the machine head, the most effective and simple one is to install it on the main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com