K-type disc proportional electromagnet

A proportional electromagnet and disk-type technology, applied in the field of proportional electromagnets, can solve problems such as poor proportional characteristics, limited output force improvement, and limited stroke structure, achieve good level characteristics, improve output force and working stroke, and structural technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

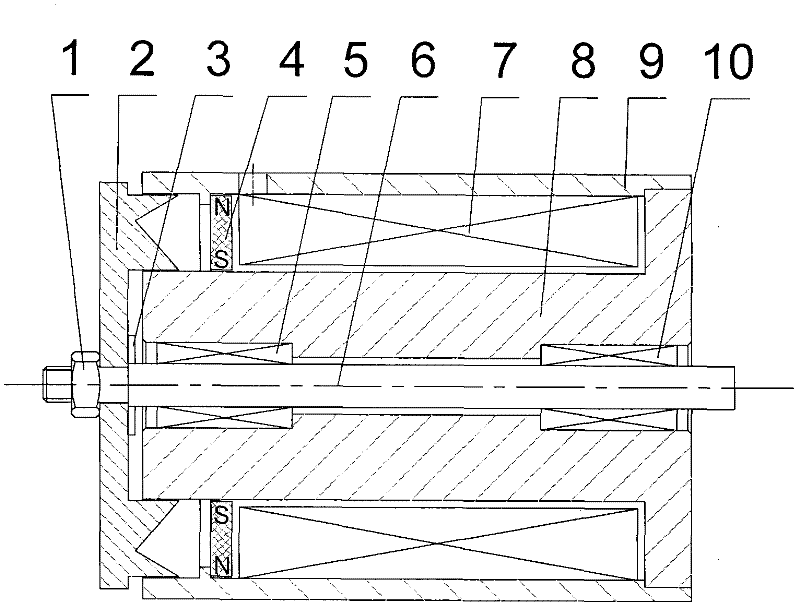

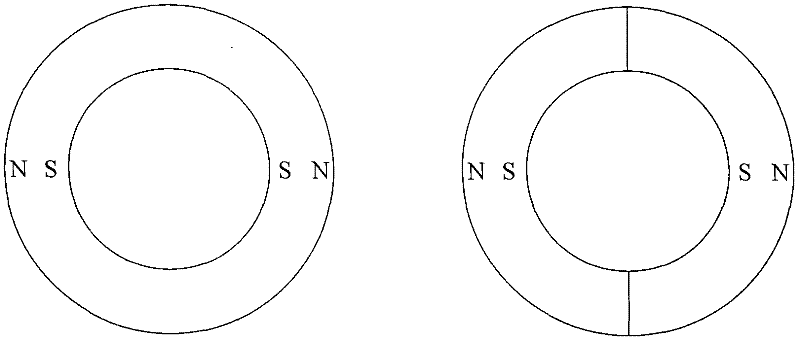

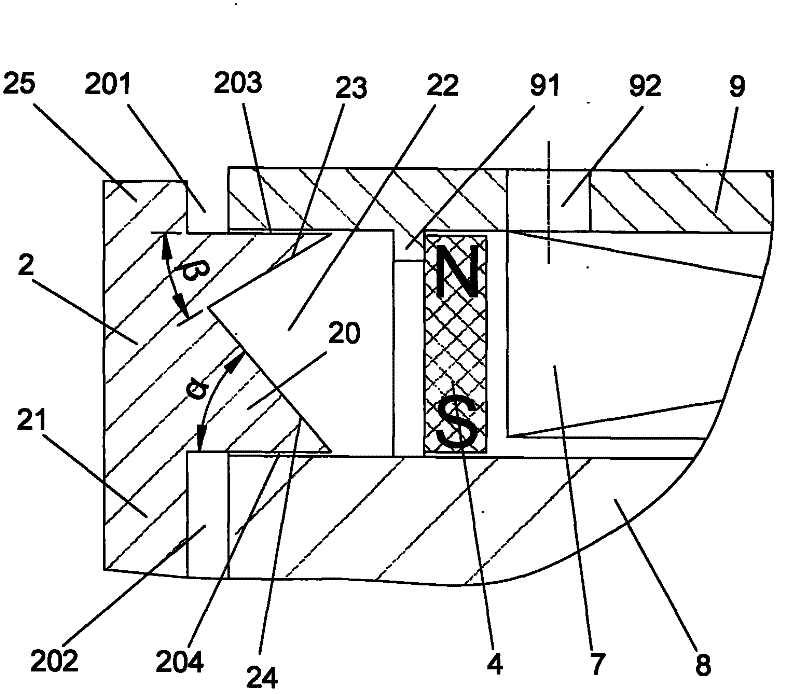

[0033] Figure 1 ~ Figure 3 Combined with a k-type disc proportional electromagnet, it includes a fixed nut 1, an armature 2 with a "k"-shaped longitudinal section, a limit piece 3, a permanent magnet 4, a push rod 6, a control coil 7, and a hollow space inside. The magnetically conductive core column 8 of the cavity, the hollow magnetically conductive outer casing 9; the armature 2, the magnetically conductive core column 8 and the magnetically conductive outer casing 9 are all made of soft magnetic materials, and the push rod 6 is made of nonmagnetically conductive materials.

[0034] The magnetically conductive outer shell 9 is a hollow cubic shell, and the magnetically conductive core column 8 is set in the inner cavity of the magnetically conductive outer shell 9, and the magnetically conductive core column 8 is fixedly connected with the magnetically conductive outer shell 9; The permanent magnet 4 and the control coil 7 are arranged in the annular space formed by 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com