Four-point distribution power assembly suspension device

A technology of powertrain and suspension, which is applied in the direction of power device, control device, jet propulsion device, etc., can solve the problems of poor vibration isolation performance and occupation of upper body space, and achieve long service life, extended service life and vibration isolation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

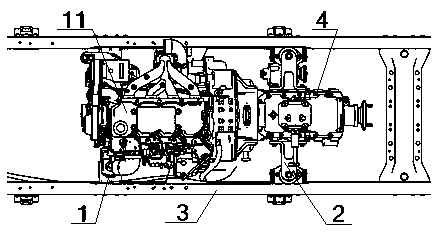

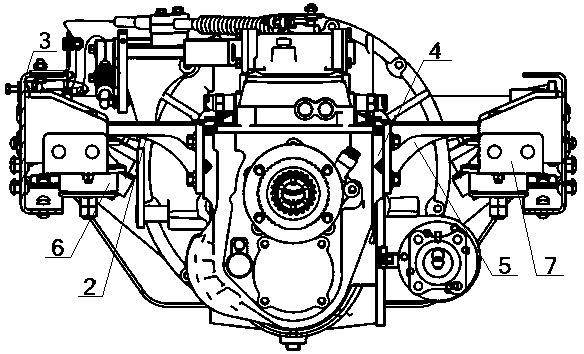

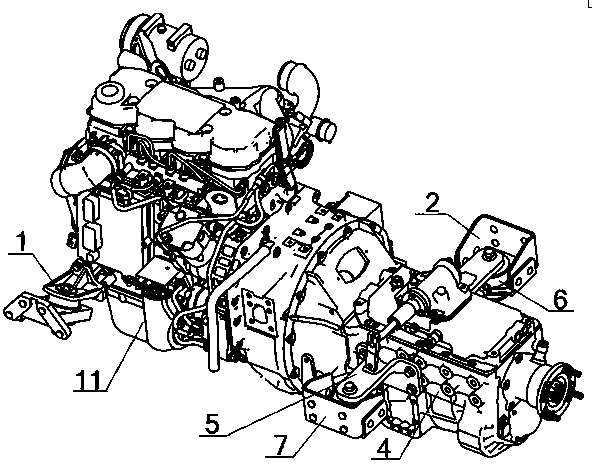

[0059] see figure 1 – Figure 8 , a four-point arrangement type powertrain mount, comprising a front mount 1 and a rear mount 2, one end of the front mount 1 is fixedly connected to the engine casing 11, and the other end of the front mount 1 is connected to the vehicle The frame longitudinal beam 3 is fixedly connected, one end of the rear suspension 2 is fixedly connected with the side plate 4 of the gearbox housing, the other end of the rear suspension 2 is fixedly connected with the frame longitudinal beam 3, and one end of the rear suspension 2 It is fixedly connected with the middle part of the side plate 4 of the transmission case, and the other end of the rear suspension 2 is fixedly connected with the frame longitudinal beam 3. The rear suspension 2 includes a suspension bracket 5, a suspension cushion assembly 6 and a suspension bracket 7, the top of the suspension cushion assembly 6 is fixedly connected to the middle part of the side plate 4 of the gearbox casing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com