Paint spraying system for monitoring equipment

A technology for monitoring equipment and painting booths, which is applied in the field of painting systems for monitoring equipment, which can solve the problems of immobile nozzles, reduced processing efficiency of workpieces, and inability to spray paint, etc., to achieve the effect of convenient loosening, improving painting efficiency, and convenient painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

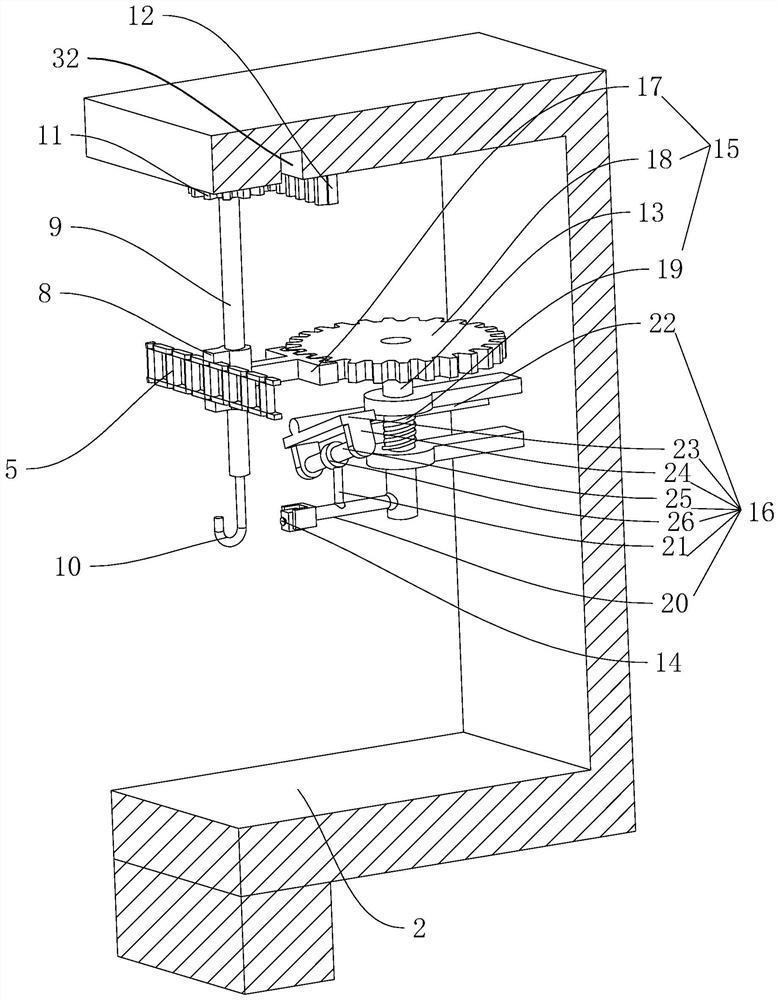

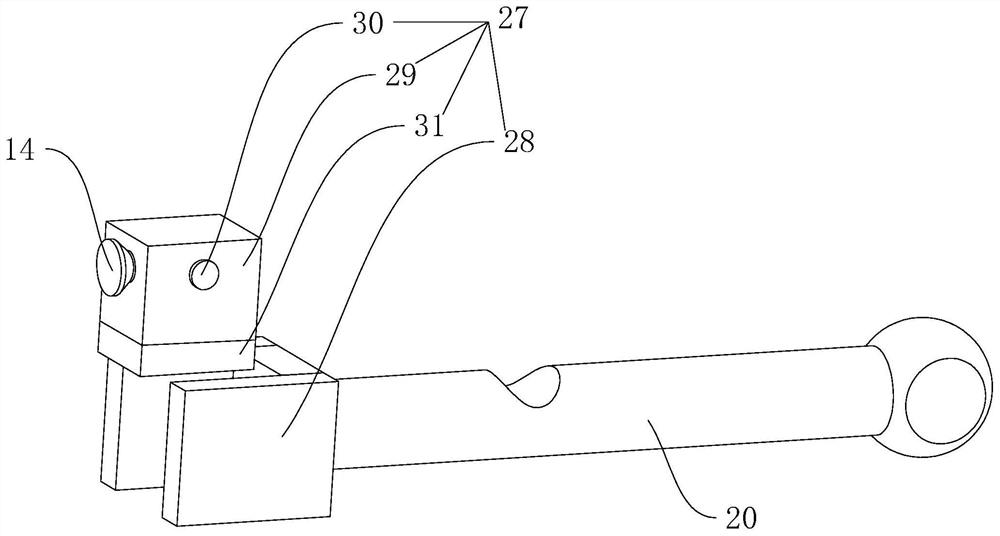

[0032] The following is attached Figure 1-4 The application is described in further detail.

[0033] The embodiment of the present application discloses a painting system for monitoring equipment.

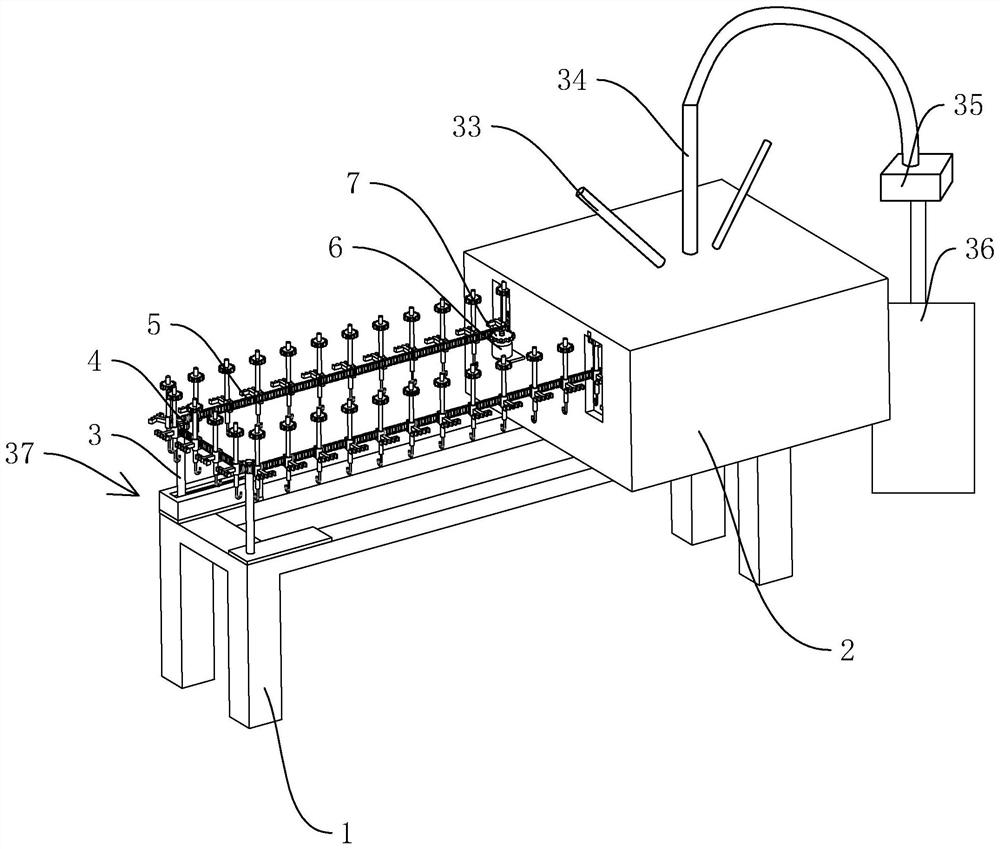

[0034] Such as figure 1 As shown, a painting system for monitoring equipment includes a bracket 1, a paint spraying room 2 is fixedly connected to the upper surface of one end of the bracket 1, and two are provided on the side of the painting room 2 away from the same end of the bracket 1 to facilitate workpieces entering and leaving the painting room. 2 through-holes.

[0035] Such as figure 1 As shown, a support rod 3 is fixedly connected to both sides of the end of the bracket 1 away from the paint spraying room 2 and the side of the paint spraying room 2 close to the same end face of the support 1. The support rod 3 is L-shaped. 3 One end is fixedly connected with a driving gear 4, and a driving chain 5 is wound between the four driving gears 4, and a driving motor 6 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com