Positioning jig of hole system welding platform

A welding platform and positioning fixture technology, which is applied in the field of positioning and clamping of workpieces on welding workbenches, can solve the problems of high cost of positioning parts, vertical deviation of the insertion rod, and affecting positioning accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

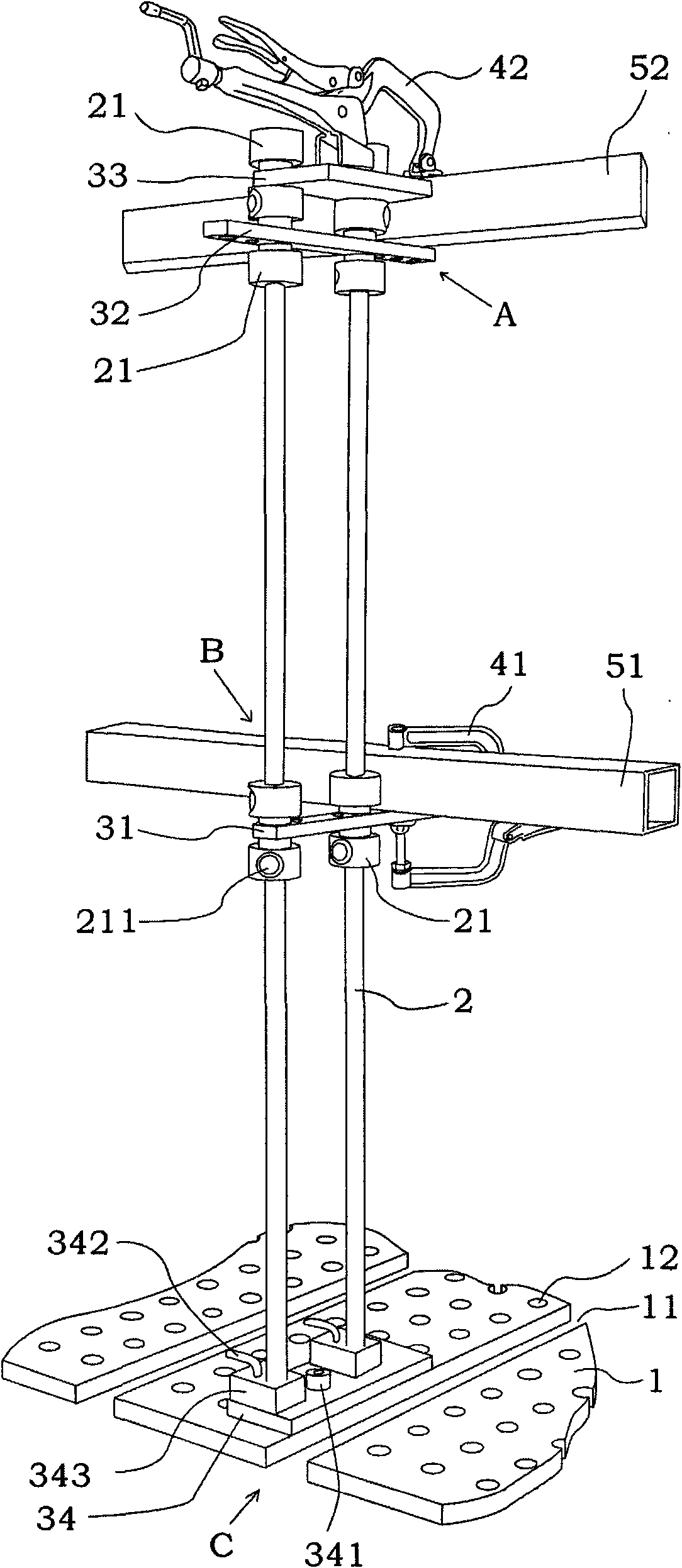

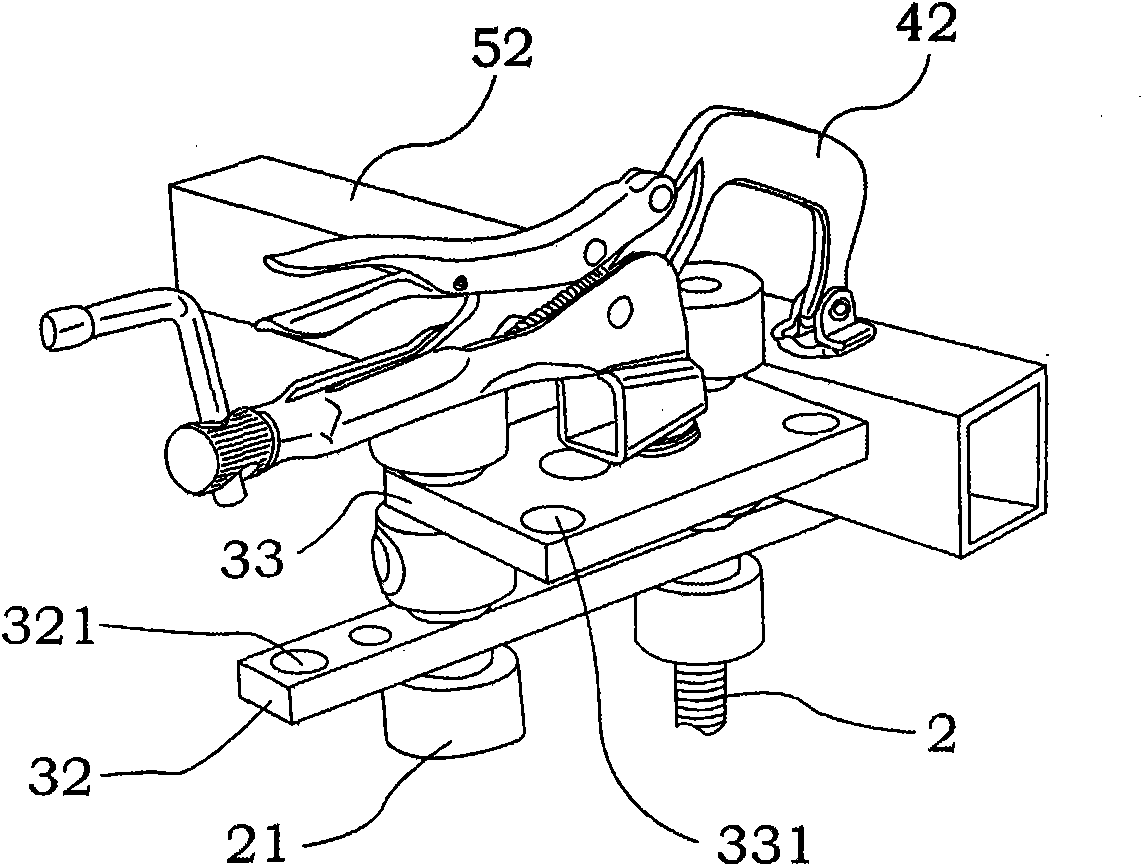

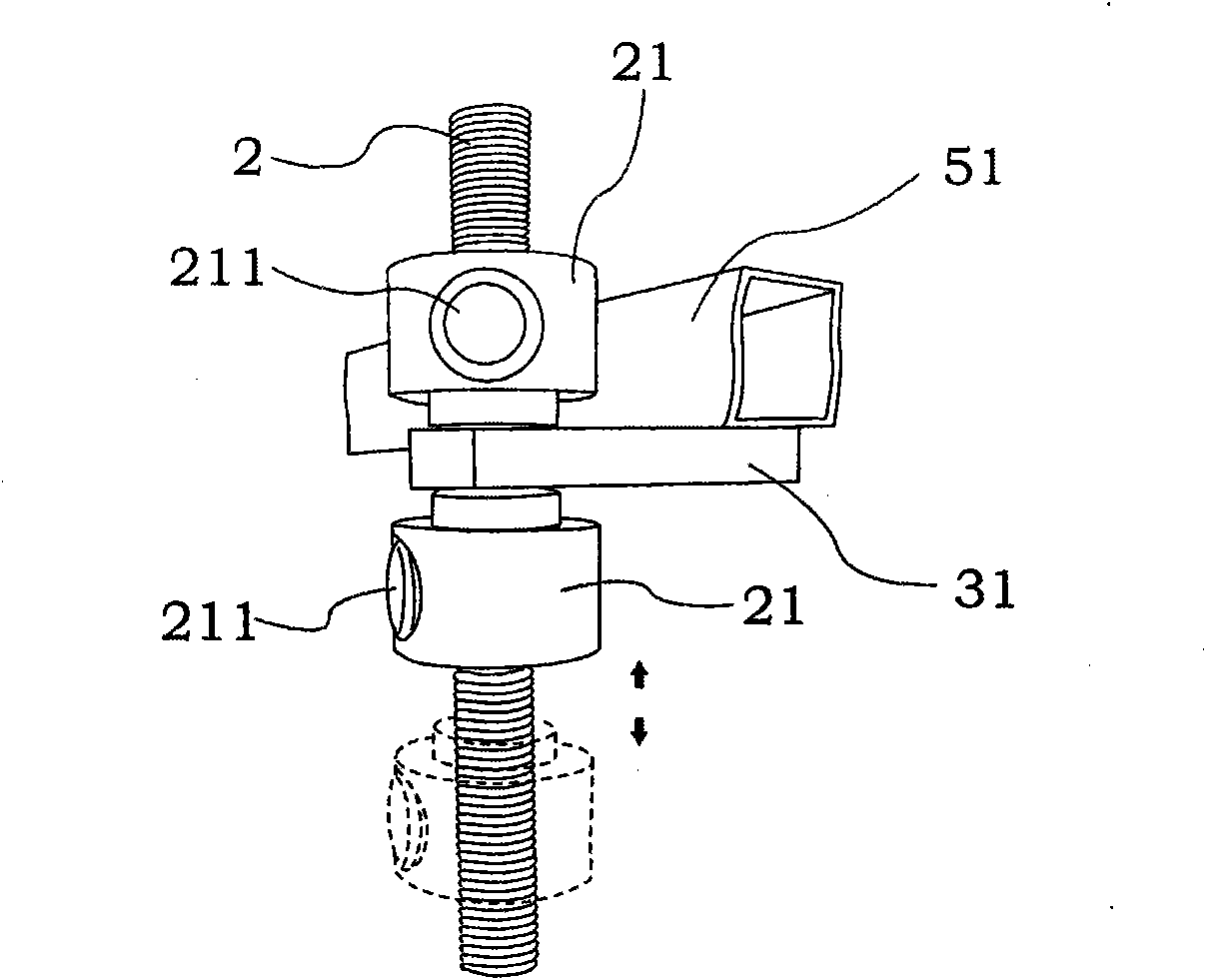

[0019] like Figure 1 to Figure 3 The slots shown are combined with the positioning fixture of the welding workbench. There are positioning grooves 11 between the adjacent strip-type welding worktops 1 of the workbench. Cylindrical positioning holes 12 are evenly opened on the welding worktop 1. Through the locking pin 341 , the connecting plate 34 is fixed on the table top 1, two positioning blocks 343 are arranged on the connecting plate 34, and a half nut is respectively arranged inside each positioning block 343, and the inner screw hole formed by the half nut is just in line with the welding table 1 Corresponding to the corresponding positioning hole 12 on the top, insert the two screw rods 2 into the inner screw holes and lock them through the locking handle 342; an appropriate number of fast forward and backward nuts are screwed on each screw rod 2, and the fast forward and backward nuts have A nut sleeve 21 and a fast forward and backward button 211, the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com