Anti-knotting textile equipment

A technology of textile equipment and fixing seat, which is applied in the field of anti-knotting textile equipment, can solve the problems of inability to adjust the processing quantity, low textile quality and efficiency, and long time consumption, so as to improve textile quality and efficiency, and improve textile quality , the effect of preventing knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

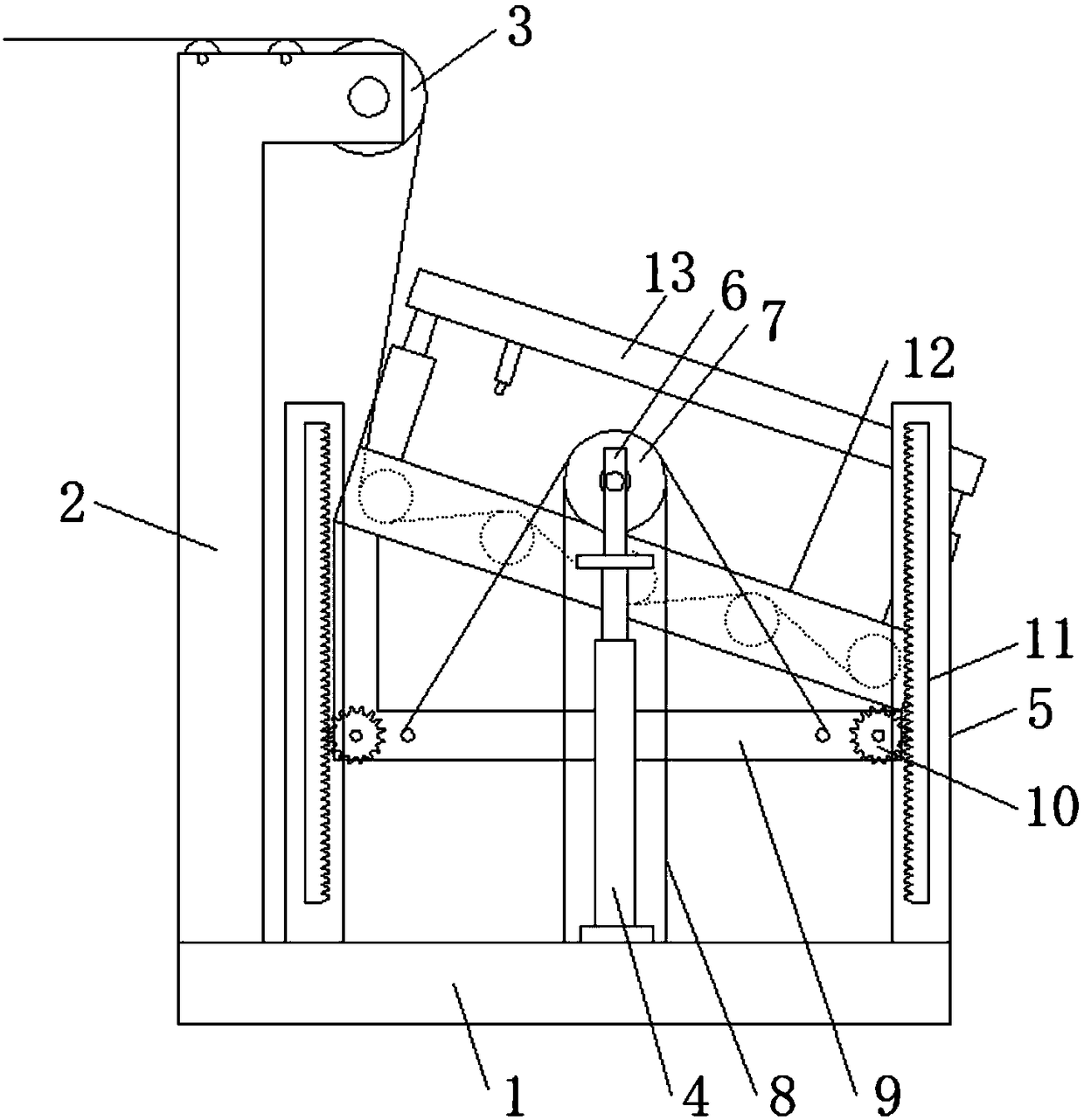

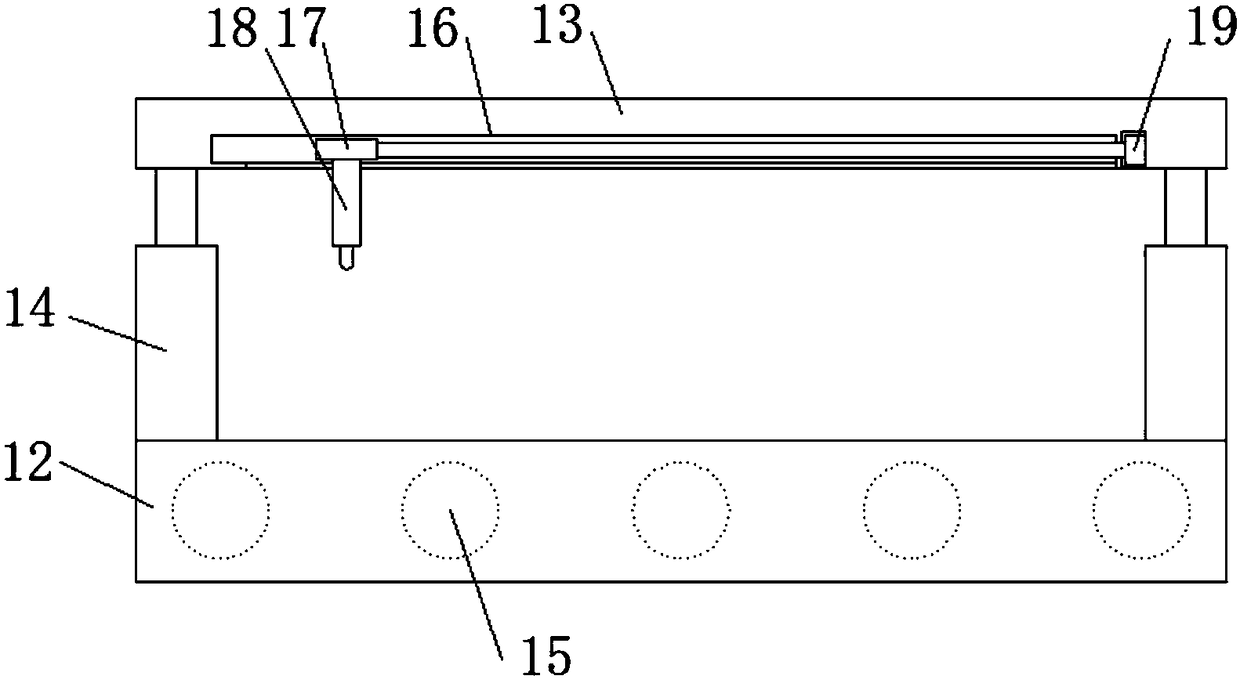

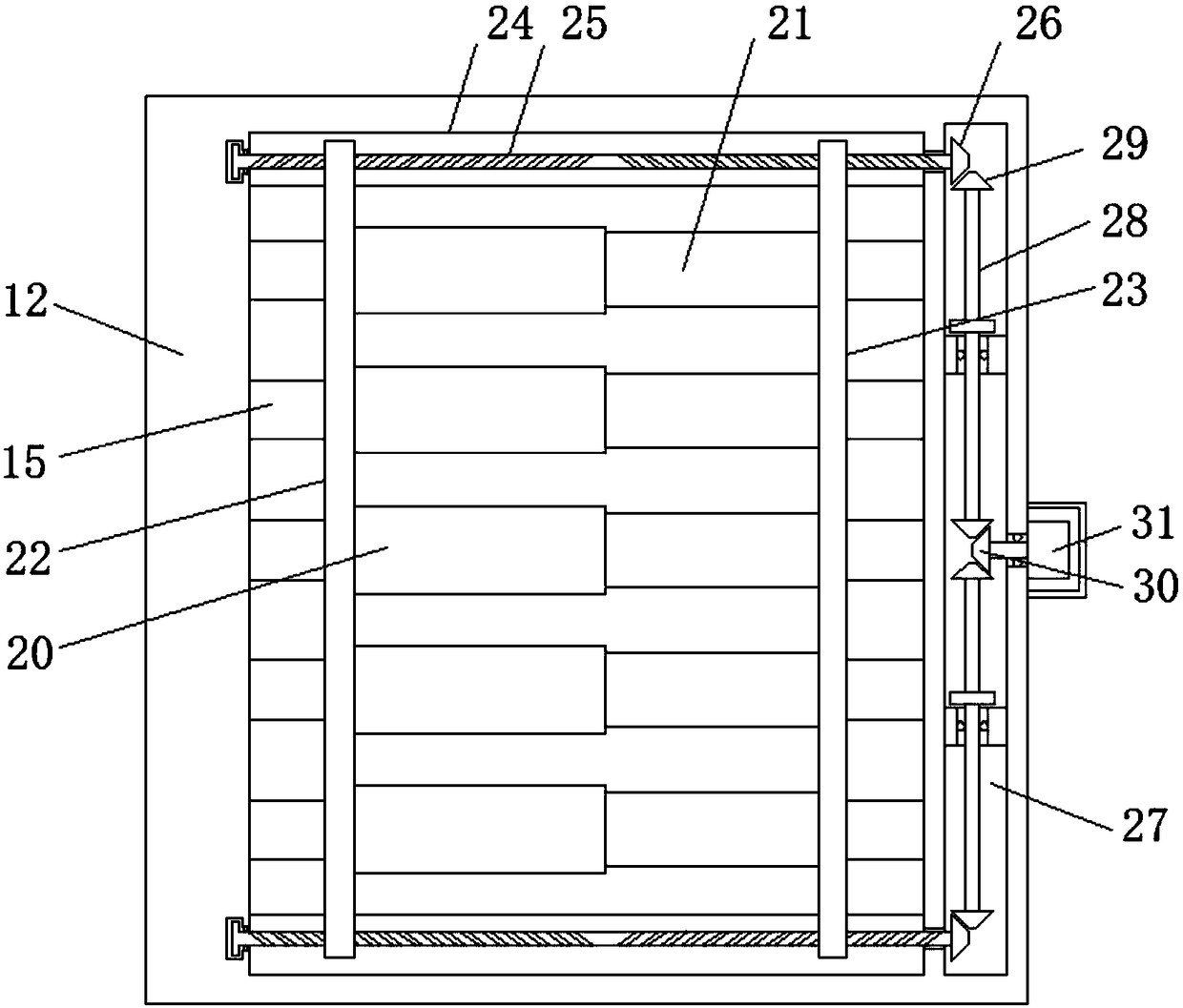

[0025] refer to Figure 1-4 , a kind of anti-knotting textile equipment, comprising a fixed seat 1, and also includes an orientation mechanism, a tension mechanism and a winding mechanism arranged on the top of the fixed seat 1;

[0026] The tensioning mechanism comprises a first driving device 4 and a guide plate 5 which are vertically installed on both sides of the top of the fixed seat 1, and the guide plate 5 is located on both sides of the first driving device 4, and the top of the first driving device 4 is equipped with an up-and-down movement Fixed mount 6, pulley 7 is installed in the fixed mount 6, is wound with two groups of steel ropes 8 arranged side by side on the pulley 7, and one end of steel rope 8 is connected to the top of fixed seat 1 respectively, and four guide plates 5 are arranged There is a balance lifting plate 9 arranged horizontally, and the other ends of the steel ropes 8 are respectively fixedly connected to both sides of the balance lifting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com