Patents

Literature

50results about How to "Improve textile quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

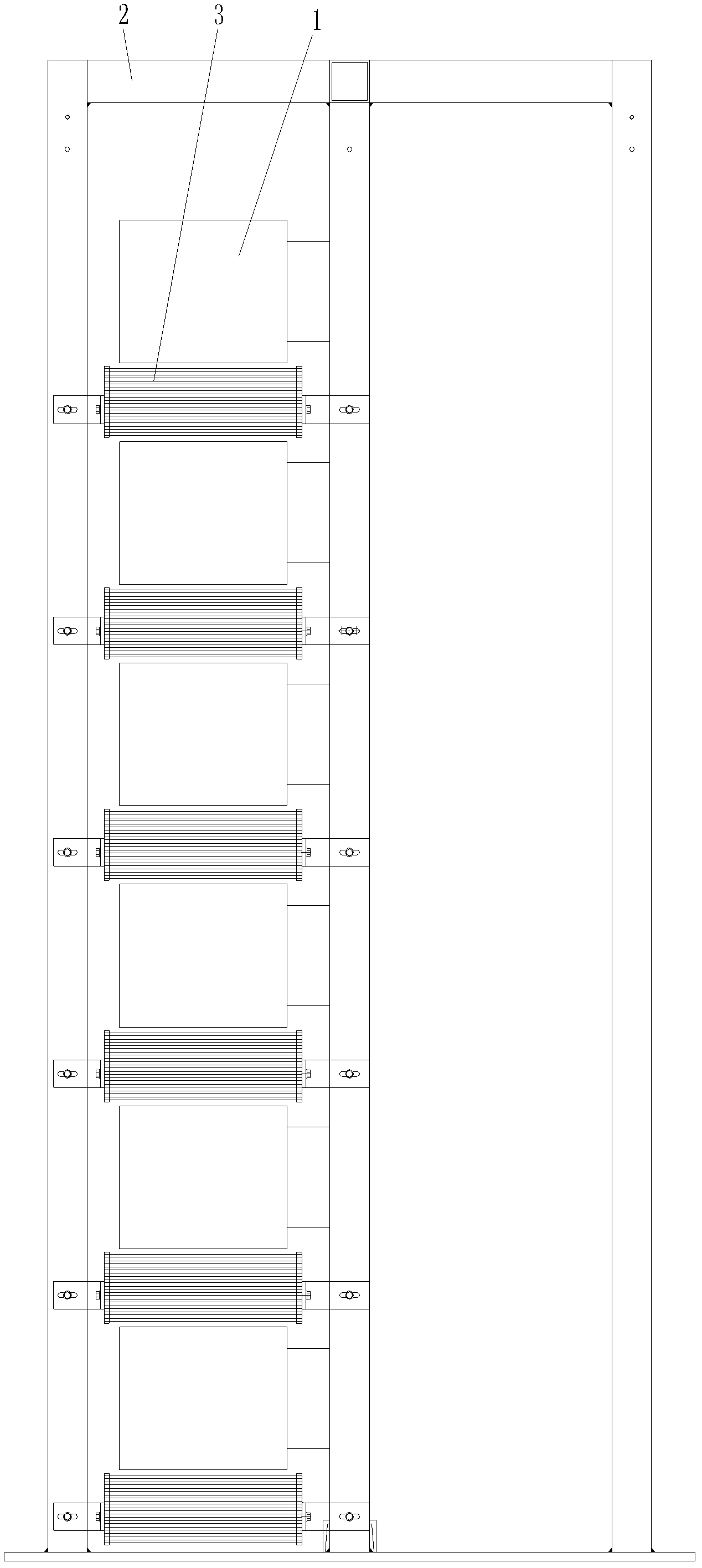

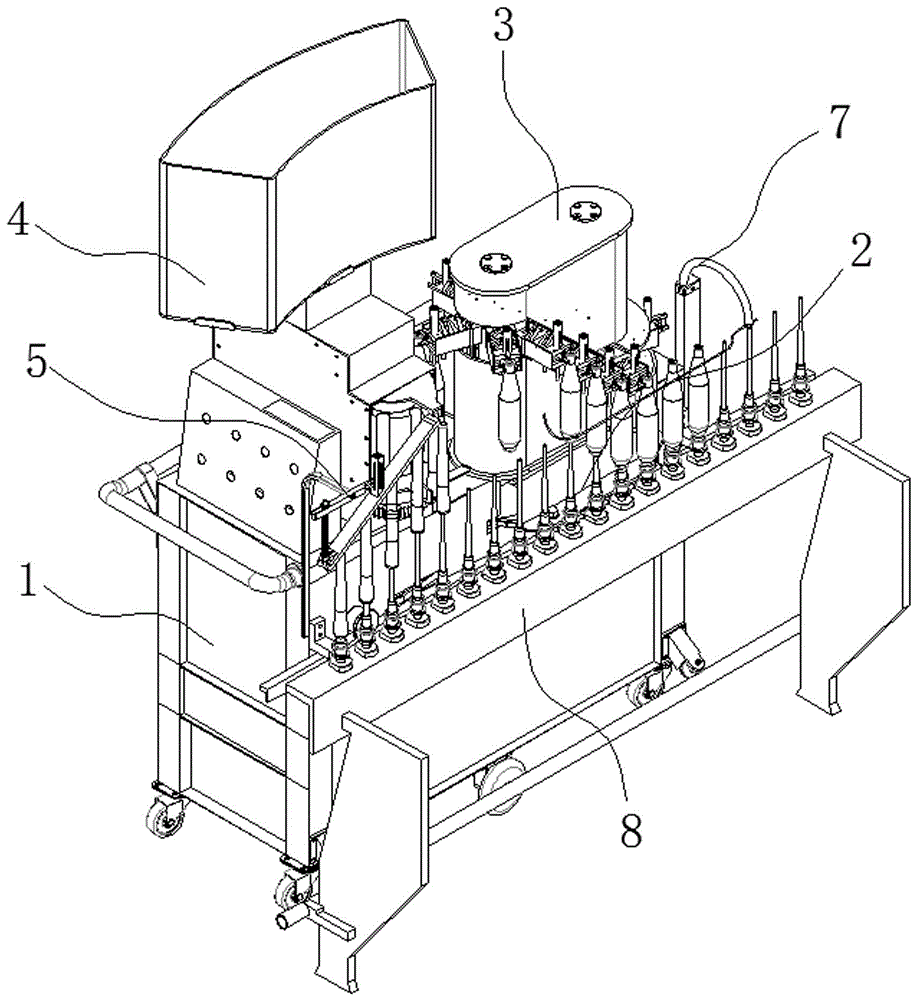

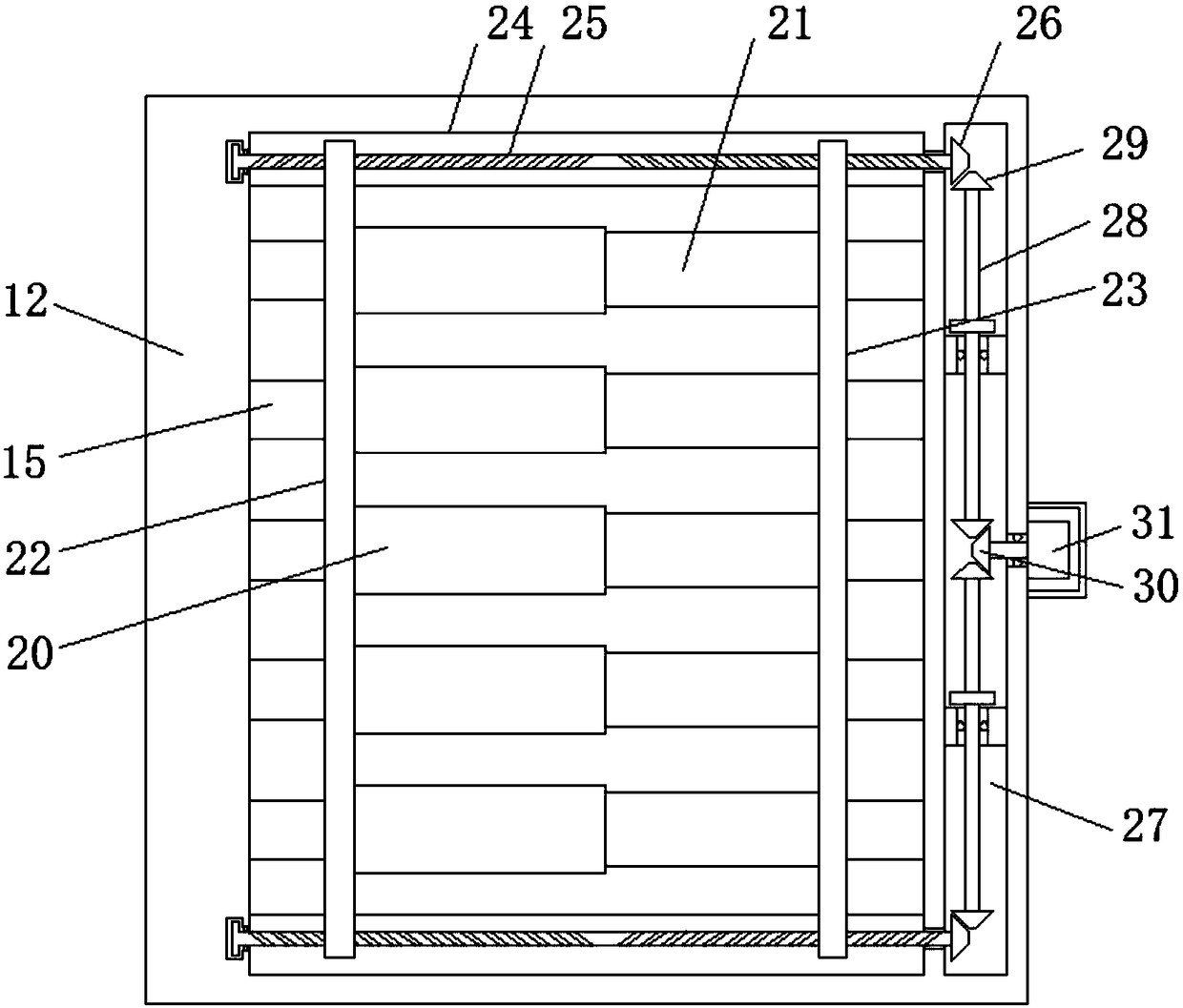

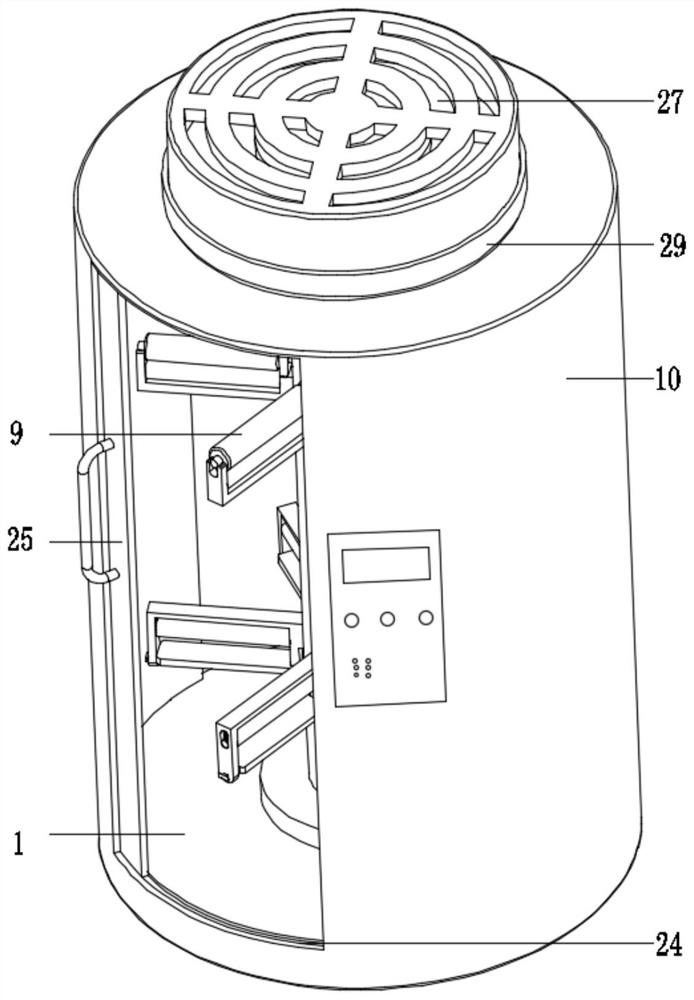

Cloth sterilization and dust removal device for automatic textile machinery

InactiveCN112501892AImprove cleanlinessEasy to collectMechanical cleaningPressure cleaningDust controlMechanical engineering

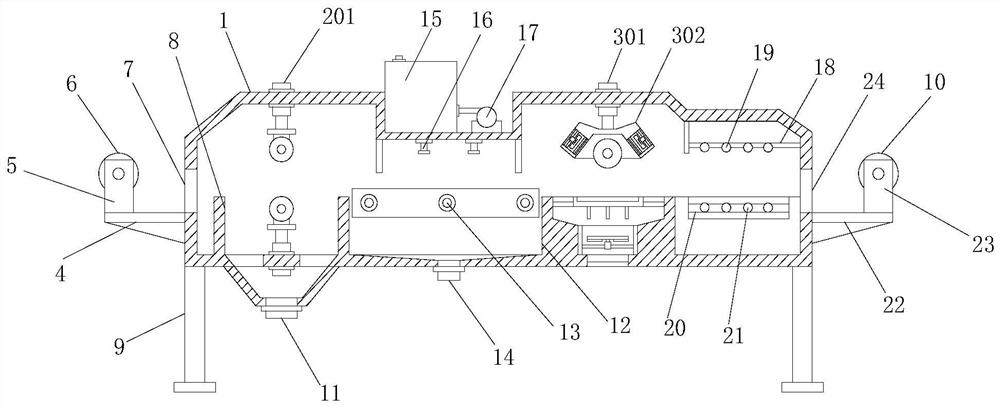

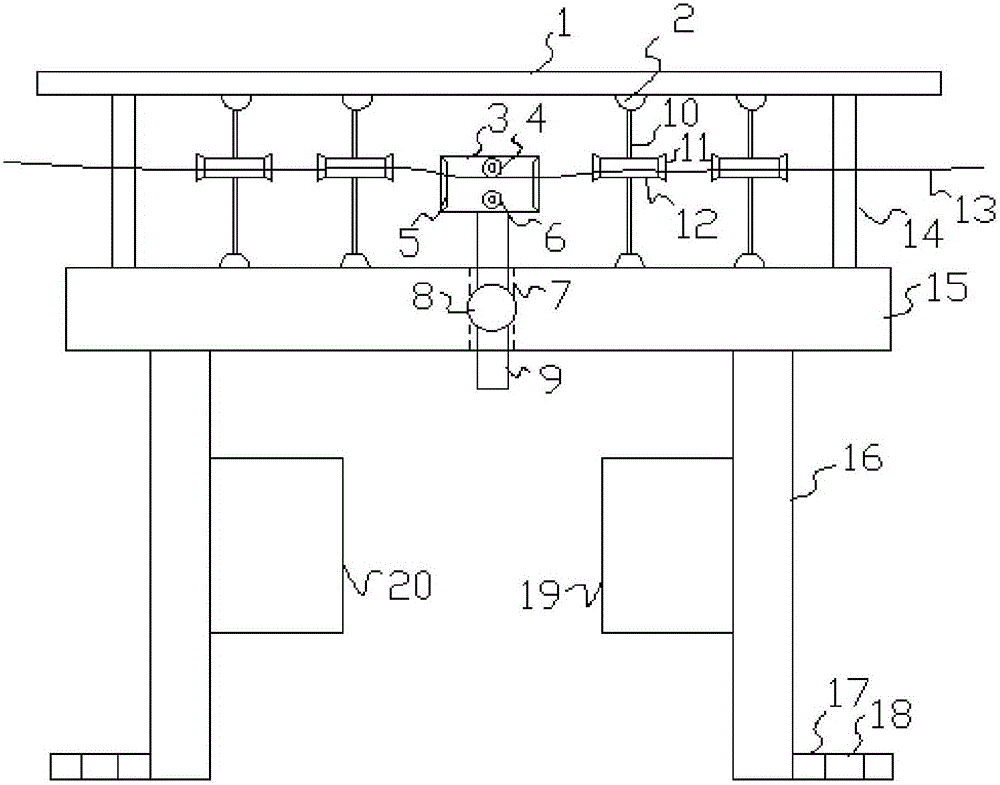

The invention relates to the technical field of textile machinery, and discloses a cloth sterilization and dust removal device for automatic textile machinery. The cloth sterilization and dust removaldevice comprises a machine body, a dust removal mechanism and a drying and wrinkle removal mechanism; the dust removal mechanism is arranged on the left side in the machine body; and the drying and wrinkle removal mechanism is arranged on the right side in the machine body. According to the cloth sterilization and dust removal device for the automatic textile machinery, a first fixing frame and asecond fixing frame are adjusted to proper positions by starting a first hydraulic telescopic cylinder and a second hydraulic telescopic cylinder, and textile cloth is clamped between a first brush roller and a second brush roller; and a first servo motor and a second servo motor are started to drive the first brush roller and the second brush roller to rotate, the surface of the textile fabric is swept, dust accumulated on the surface is removed, the dust falls into a dust receiving groove to be collected, the structure is simple, the dust on the surface of the textile fabric is swept conveniently, the dust is easy to collect, and the dust removal efficiency is high.

Owner:绍兴嘉越纺织机械有限公司

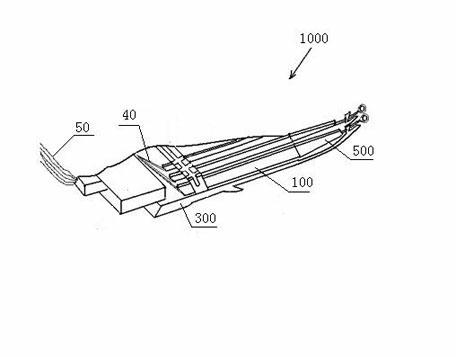

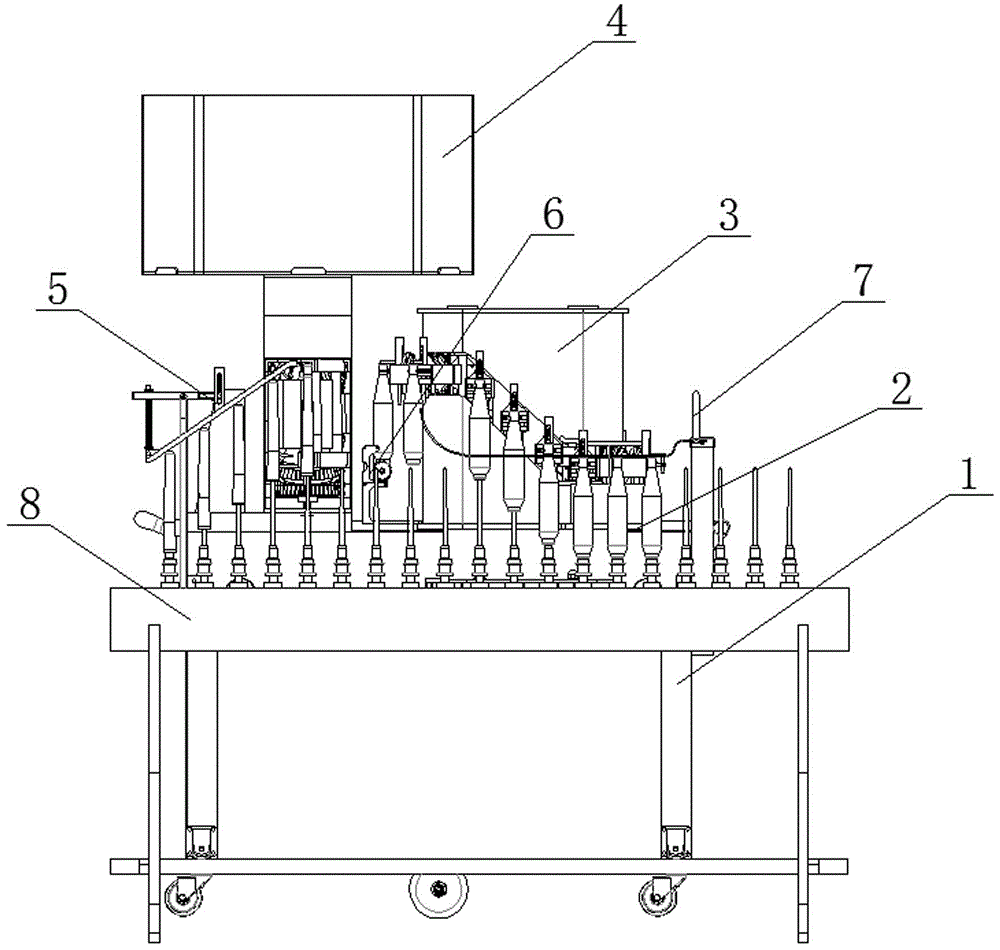

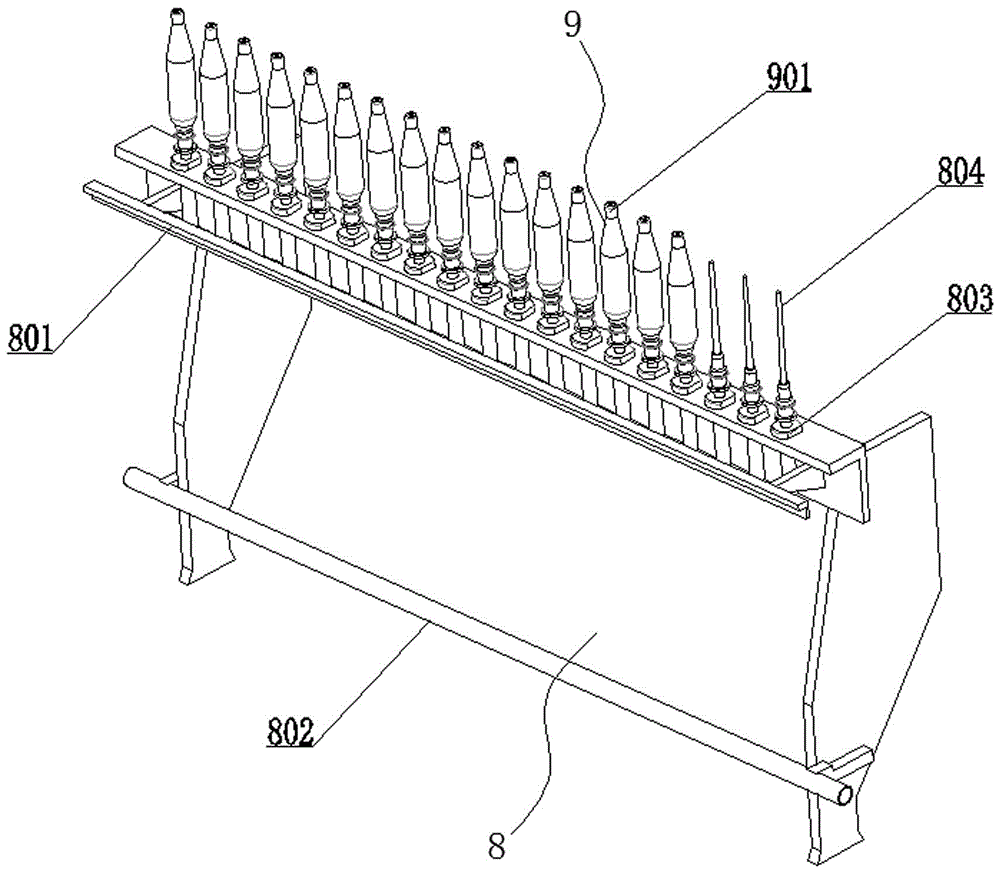

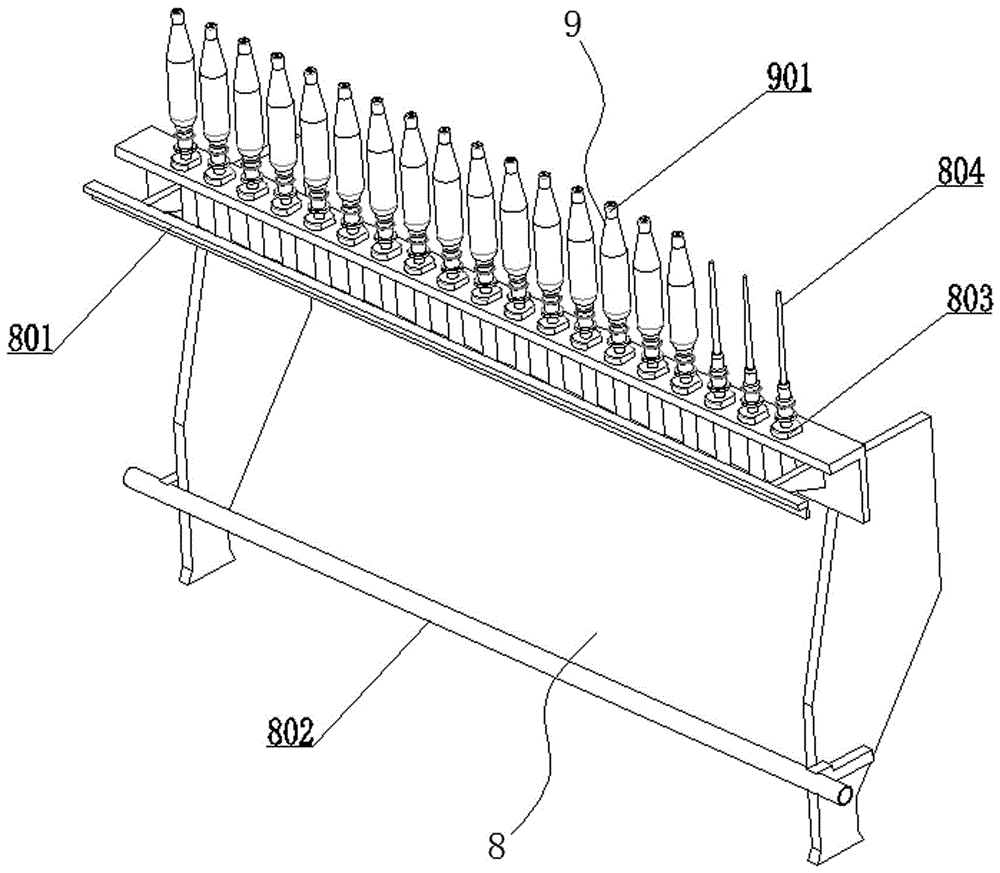

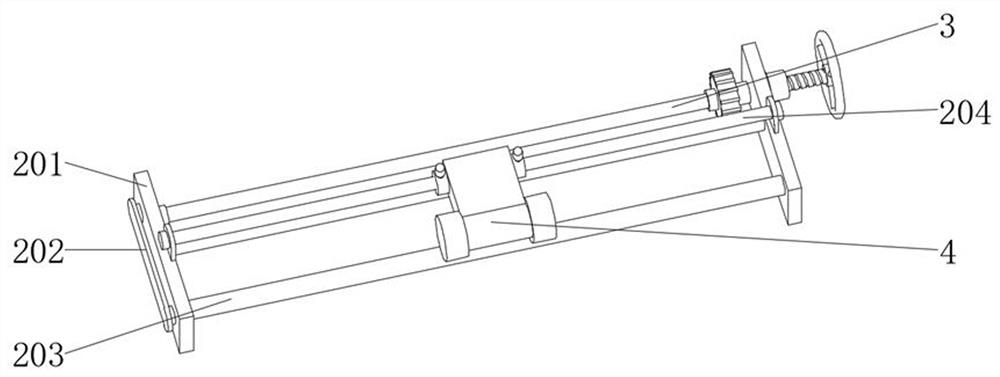

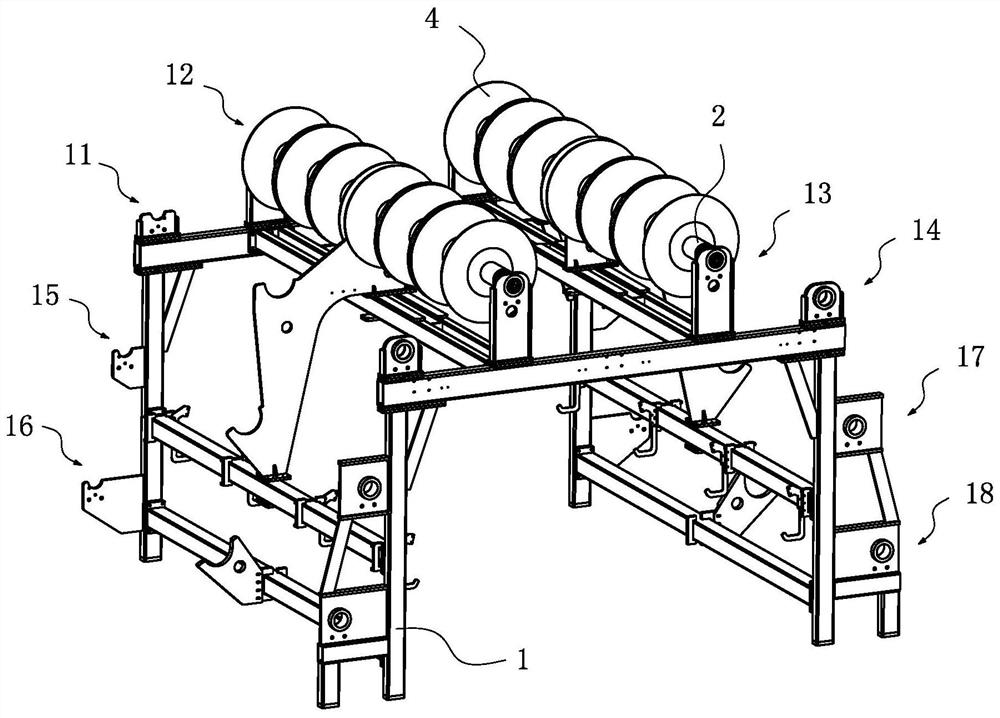

Multi-axial carbon fiber yarn zero-degree threading device

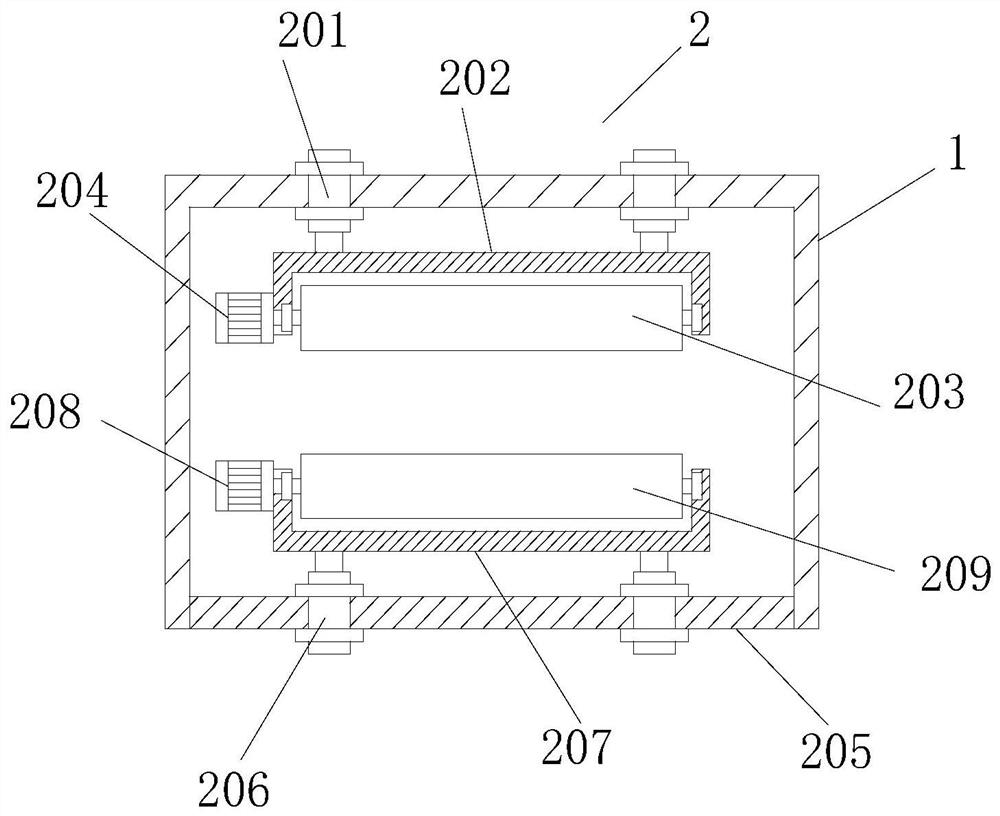

The invention relates to a multi-axial carbon fiber yarn zero-degree threading device, which comprises a creel and a first guide mechanism at the yarn outlet end of the creel, wherein a first yarn transition support and a second yarn transition support are sequentially arranged at one side of the creel, a second guide mechanism is arranged on the first yarn transition support, a third guide mechanism and a guide plate which is positioned behind the third guide mechanism are arranged on the second yarn transition support, at least a first line of guide holes and a second line of guide holes which is positioned below the first line of guide holes are arranged in the guide plate, both the first and the second lines of guide holes comprise a plurality of guide holes with the same space, and the right end of the first guide hole in the first line of guide holes is vertically intersected with the left end of the guide hole which is in the second line of guide holes and corresponds to the first guide hole; and a jacking device is arranged below the creel, the carbon fiber yarn comes out from the creel to a knitting machine, the device can prevent the surface of the carbon fiber yarn fromgenerating broken filaments, when the carbon fiber yarn enters the knitting machine, no clearance is left between the adjacent carbon fiber yarns, so the knitting quality of a carbon fiber yarn knitting product is improved.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

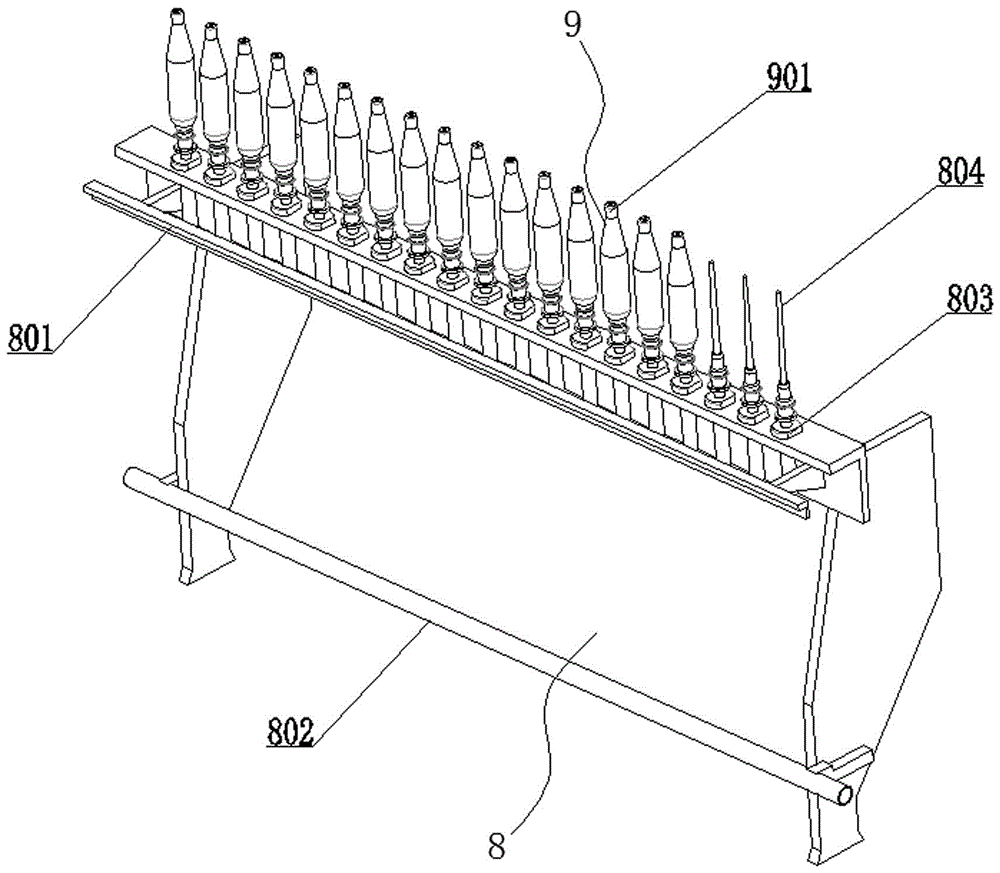

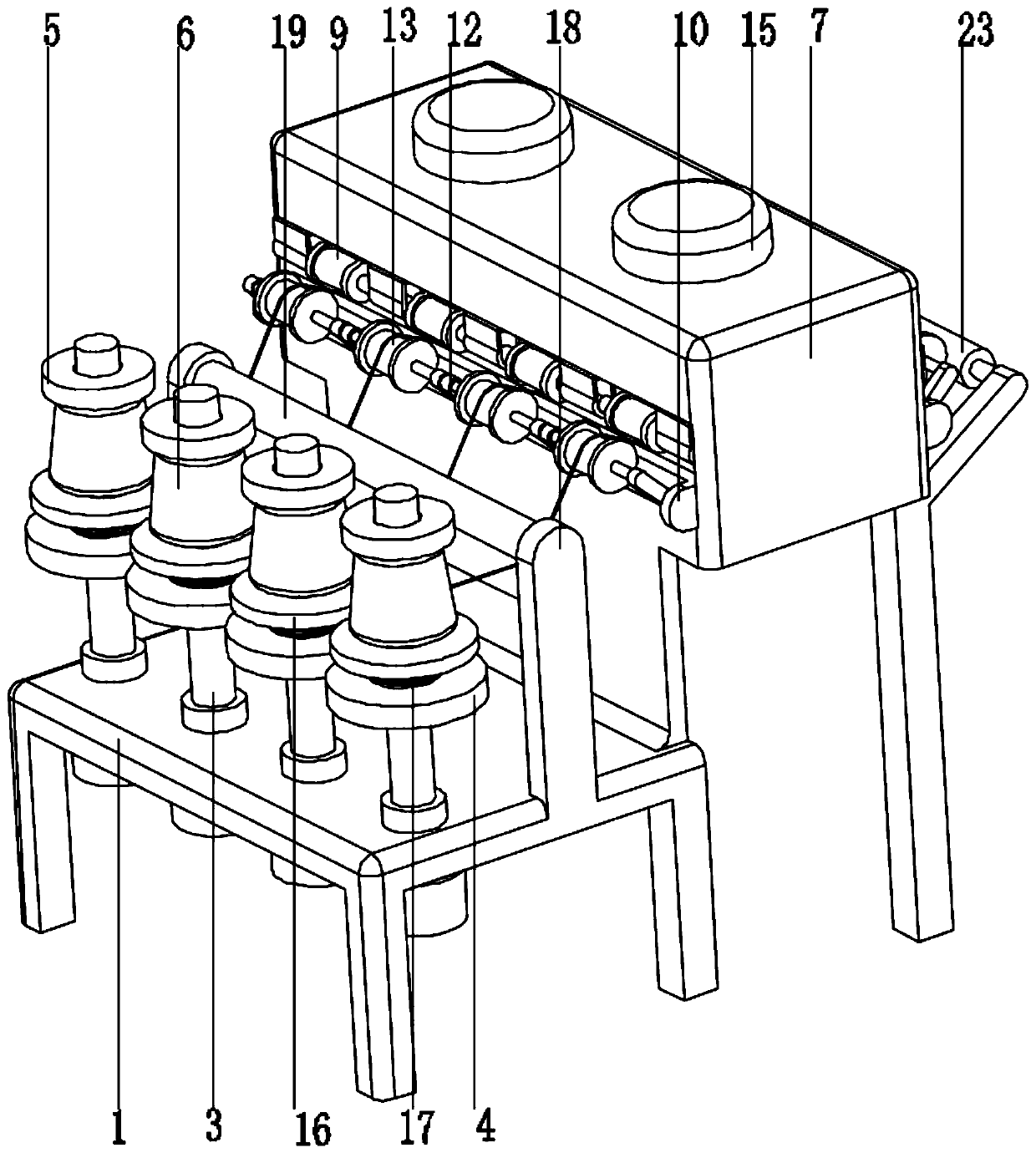

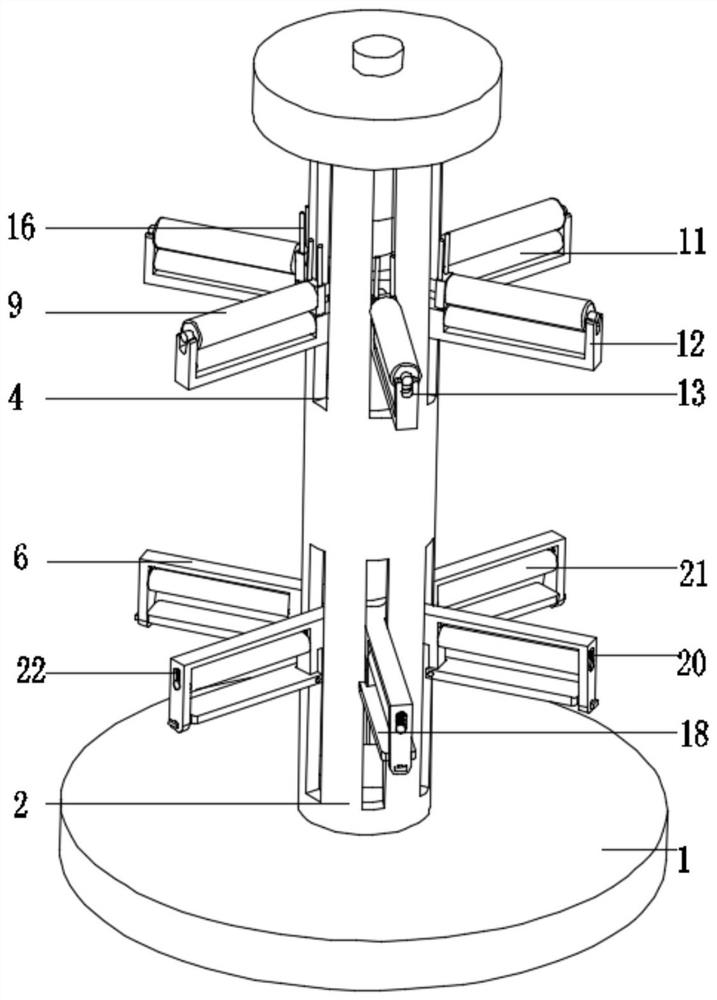

Bobbin blanking and conveying device of fine spinning doffing machine

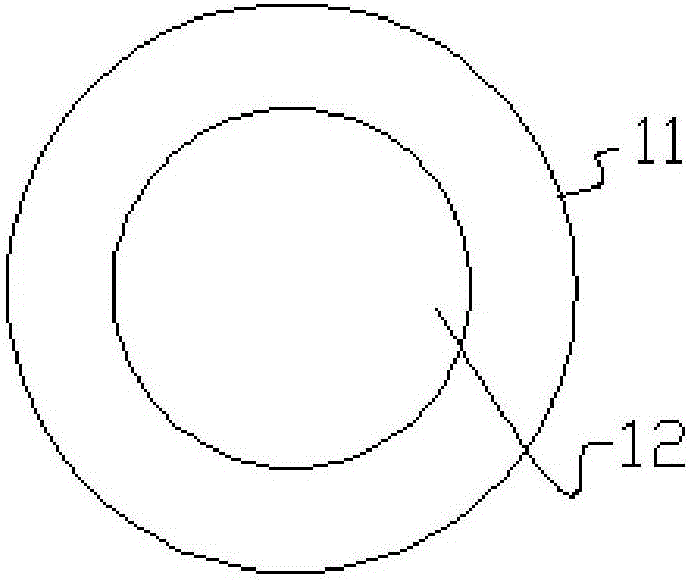

The invention relates to a bobbin blanking and conveying device of a fine spinning doffing machine. The bobbin blanking and conveying device of the fine spinning doffing machine is characterized by comprising an upper frustum guide disc mounting base, a lower frustum guide disc mounting base, more than two stages of frustum guide discs, a guide disc transmission shaft, a guide disc transmission gear, a guide disc power input gear, an insert tube power input gear and a bobbin cage, and a fussy bobbin bin does not need to reciprocate and shake the device, so that the influence of the bobbin bin on the doffing machine due to vibration while reciprocating and shaking is completely eradicated, and angular transformation of a bobbin in a controllable state is realized. The bobbin blanking and conveying device rotates into a 90-degree upright state through 'S'-shaped displacement from a 180-degree horizontal position, and by virtue of equal-pitch synchronous displacement of the guide discs and a spindle, the spindle is accurately inserted, so that variable-angle insert tube forms of existing various doffing machines are changed.

Owner:荣德明

Yarn anti-breaking impurity removal conveying device for textile production

InactiveCN110937456AAvoid breakingImprove textile efficiencyFilament handlingFibre cleaning/openingYarnElectric machinery

The invention discloses the technical field of textile equipment, and provides a yarn anti-breaking impurity removal conveying device for textile production. The yarn anti-breaking impurity removal conveying device for textile production comprises a conveying frame, a yarn feeding assembly comprises a yarn feeding motor fixedly mounted on the bottom of the conveying frame, the output end of the yarn feeding motor is fixedly connected with a yarn feeding shaft, the outer wall of the wire feeding shaft is fixedly connected with a mounting chassis, a damping assembly is arranged on the mounting chassis, the top of the conveying frame is rotatably connected with a detection roller, the outer wall of the yarn feeding shaft is in threaded connection with a pressing disc, a bobbin is arranged between the pressing disc and the mounting chassis, an impurity removal assembly comprises an impurity removal box, material openings are formed in two side walls of the impurity removal box, the lower portions of the material openings are slidingly provided with buffer upper rollers, the side walls of the material openings are fixedly connected with supporting frames, the middles of the supporting frames are rotatably connected with twisting shafts, the outer walls of the twisting shaft are fixedly connected with diagonal bracing frames, a buffer lower roller is rotatably connected between the diagonal bracing frames, and an impurity removal brush is fixedly connected to the middle of the impurity removal box. Yarn breaking is avoided, textile efficiency is improved, the yarn after impurityremoval treatment is lustrous, flat and free of impurity, and the textile quality is improved.

Owner:义乌市煊辉服饰有限公司

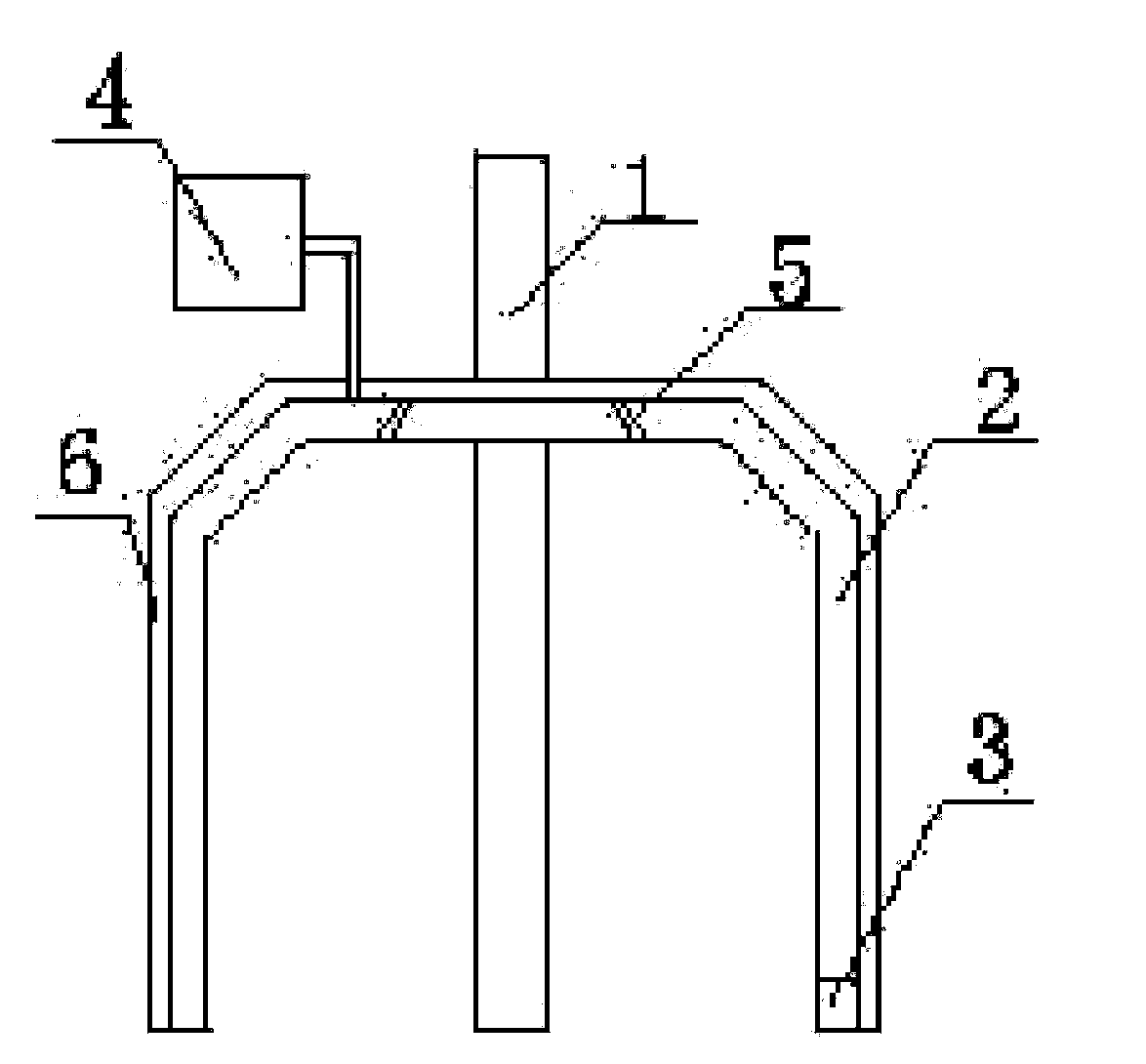

Wire guide device for spinning

The invention relates to the field of spinning, in particular to a wire guide device for spinning. The device has multiple guide parts capable of gradually guiding spinning wires or filaments into spinning equipment to prevent dust and dirt from staining on rollers. The wire guide device for spinning comprises a flat plate; the flat plate is provided with a cross bar, and is connected with the cross bar through a stand rod; a through hole is vertically formed in the middle position of the flat plate; a slide rod is arranged in the through hole; a fastening bolt for fixing the slide rod is arranged on the side surface of the flat plate; a snake pipe is transversely fixed at the top of the slide rod; an upper roller and a lower roller are arranged in the snake pipe; rubber sleeves are arranged at two ends of the snake pipe; multiple rubber cylinders are respectively arranged on the left and right two sides of the snake pipe; horn ports are formed in two ends of the rubber cylinders; and the two sides of the rubber cylinders are respectively connected with hanging lugs fixed below the cross bar and above the flat plate through rubber bands. The wire guide device for spinning is simple in operation, convenient for use and suitable for multiple spinning equipment.

Owner:SUZHOU DEHEYAXIN TEXTILE NEW MATERIAL TECH CO LTD

Anti-knotting textile equipment

InactiveCN108178026AAvoid skewAvoid easy knot problemsFilament handlingFunction indicatorsGear wheelEngineering

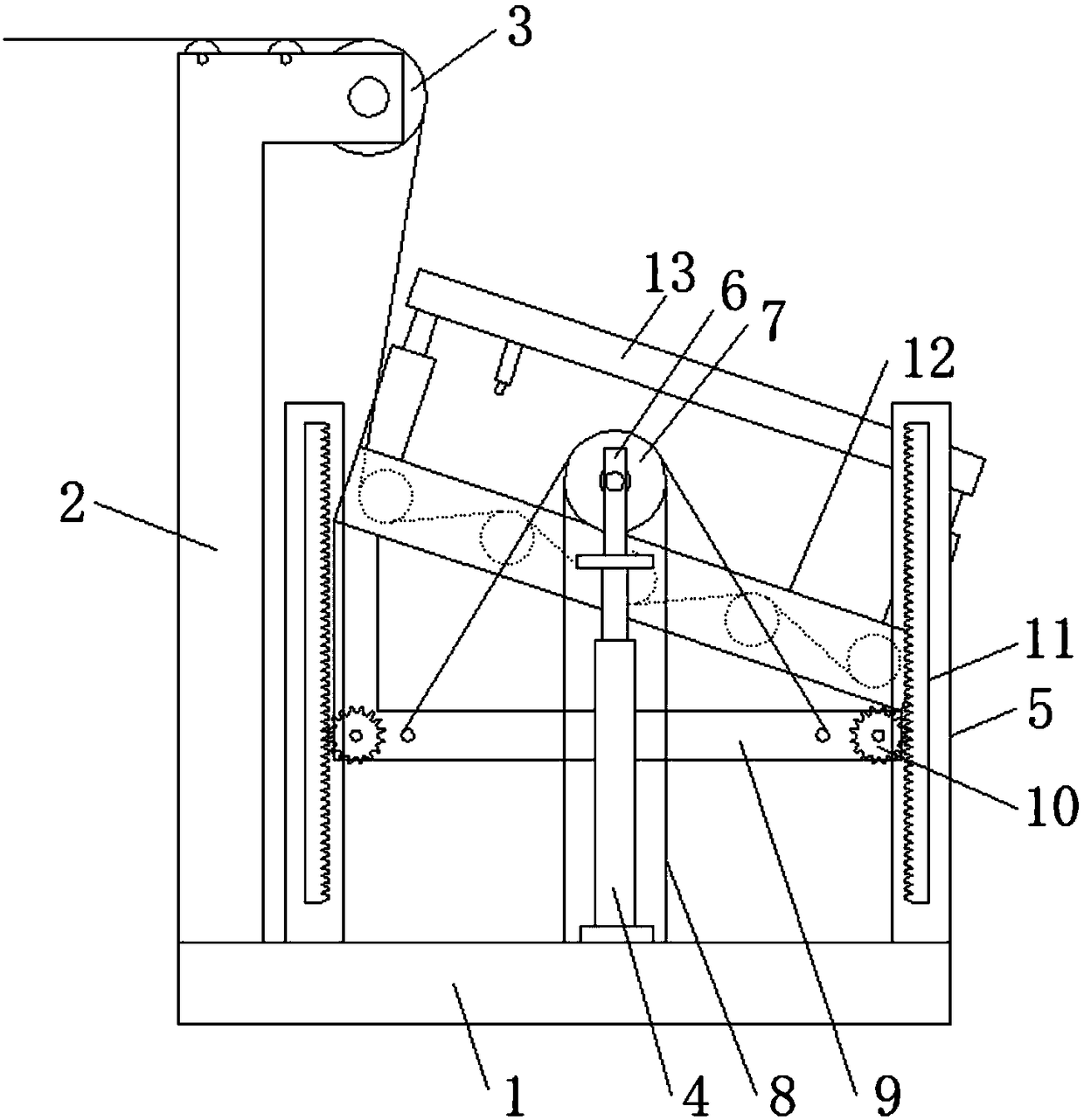

The invention discloses anti-knotting textile equipment which comprises a fixed base. The anti-knotting textile equipment further comprises an orienting mechanism, a tensioning mechanism and a windingmechanism which are arranged at the top of the fixed base. The tensioning mechanism comprises a first driving device and guide plates which are vertically installed at the two sides of the top of thefixed base. The guide plates are located at the two sides of the first driving device. A fixing rack capable of moving up and down is installed at the top of the first driving device. A pulley is installed inside the fixing rack in a rotating mode. Two sets of steel wires arranged side by side are wound onto the pulley. One ends of the steel wires are connected to the top of the fixed base. A balanced lifting plate is horizontally arranged among the four guide plates. Two sets of gears are further installed at the two sides of the balanced lifting plate. The sides, close to the balanced lifting plate, of the four guide plates are all provided with vertical racks. The anti-knotting textile equipment is reasonable in design, the tensioning degree of processed textile products can be accurately controlled, different numbers of the textile products can be positioned and adjusted, the guide effect is good, knotting of the textile products can be prevented and the textile quality and efficiency are improved.

Owner:苏州朦井纺织科技有限公司

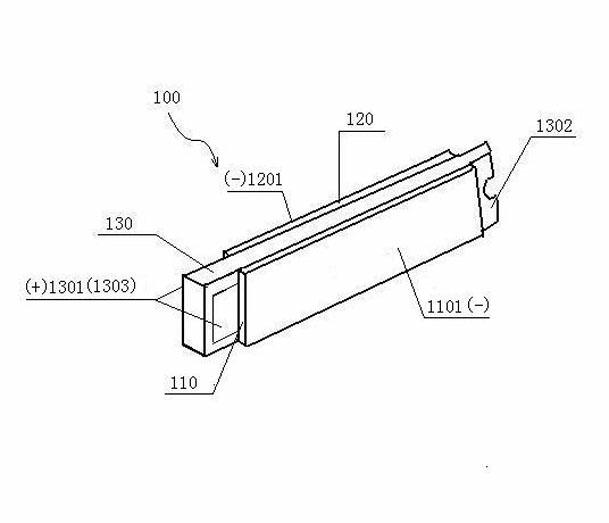

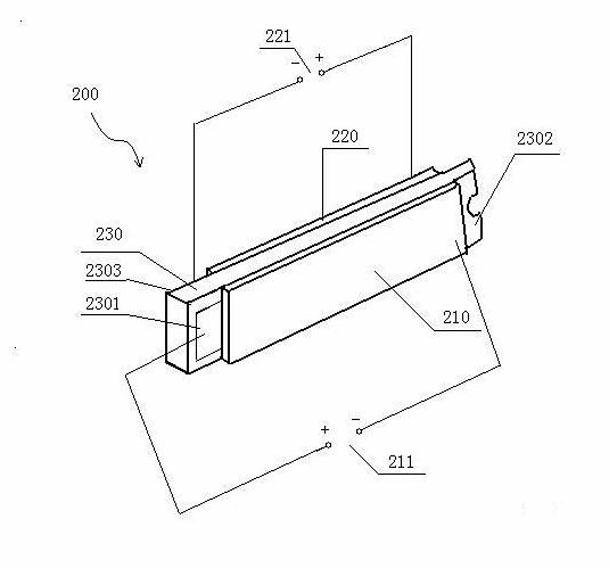

Dual-driving system and driving method of piezoelectric ceramic driving sheet for needle selector

InactiveCN102691164AIncrease swing speedImprove textile efficiency and qualityWeft knittingPiezoelectric/electrostrictive devicesElectric fieldElectricity

The invention relates to a dual-driving system of a piezoelectric ceramic driving sheet for a needle selector. The dual-driving system provided by the invention comprises dual-chip piezoelectric ceramic driving sheets, a base and power supplies. The dual-driving system is characterized in that the power supplies comprise a power supply for providing a positive electric field to one piezoelectric ceramic sheet within a same time period and a power supply for providing a negative electric field to another piezoelectric ceramic sheet, wherein the negative electric field is lower than a coercive electric field of the other piezoelectric ceramic sheet. The invention also provides a driving method of the piezoelectric ceramic driving sheet for the needle selector. The dual-driving system and the driving method thereof provided by the invention have the advantages that when the positive electric field is applied to one piezoelectric ceramic sheet for the piezoelectric ceramic driving sheet, the negative electric field is applied to the other piezoelectric ceramic sheet, so that not only can the swinging strength of the piezoelectric ceramic sheets be increased, but also the applied positive electric field can be lowered appropriately, thus improving and prolonging the safety and the service life of the piezoelectric ceramic sheet applied with the positive electric field.

Owner:芮国林 +1

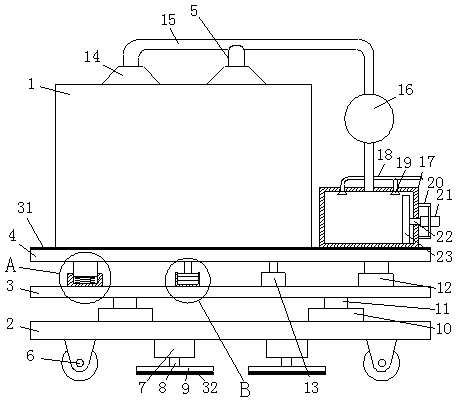

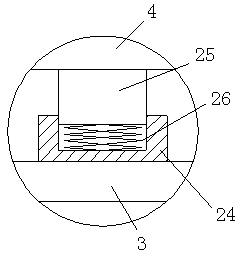

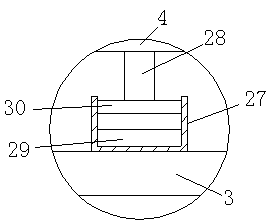

Automatic cotton yarn spinning machine

The invention discloses an automatic cotton yarn spinning machine. The automatic cotton yarn spinning machine comprises a spinning machine body and a base, the base comprises a base plate, a support plate and a mounting plate, multiple symmetrically distributed universal wheels are arranged at the bottom of the base plate, multiple symmetrically distributed first hydraulic cylinders are arranged on the top of the base plate, first telescopic rods are connected to the tops of the first hydraulic cylinders, the support plate is arranged on the tops of the first telescopic rods, multiple uniformly distributed first support columns and second support columns are arranged on the top of the support plate, the second support columns are arranged on the inner sides of the first support columns, the mounting plate is connected to the tops of the first support columns, the spinning machine body is fixed to the top of the mounting plate, and a dust collection device is arranged on the spinning machine body. The automatic cotton yarn spinning machine is simple in structure and has the good damping effect; meanwhile, dust generated when the spinning machine works can be reduced, the dust collection effect is good, and the spinning efficiency and the product quality are improved.

Owner:SUZHOU MEILU TEXTILE MASCH ELECTRONICS CO LTD

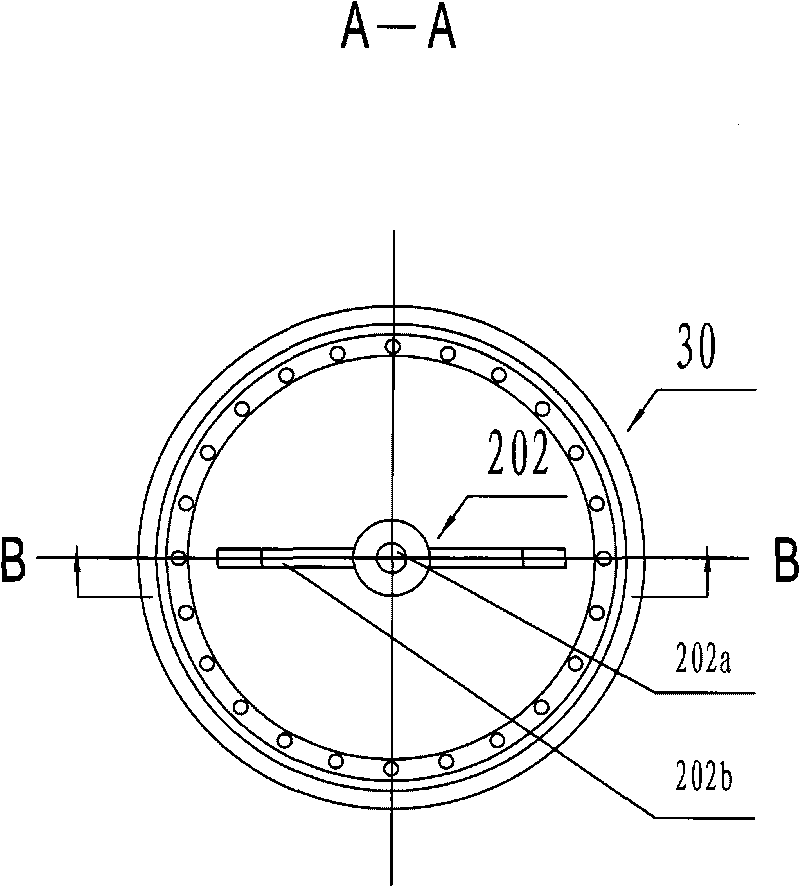

Blowing mechanisms of knitting circular weft knitting machine

The invention relates to blowing mechanisms of a knitting circular weft knitting machine, which comprise two groups of the blowing mechanisms, wherein the upper group of the blowing mechanisms use an electric fan which rotates around a rotating rod and generates a blowing effect; the lower group of the blowing mechanisms use a gas blow pipe which rotates around a rotating shaft and generates the blowing effect; and the rotation direction of the rotating rod is opposite to that of the rotating shaft. The blowing mechanisms can simultaneously process flying cotton wools of a plurality of parts, and the lower group of the blowing mechanisms adopts the gas blow pipe, so the blowing mechanisms have concentrated blowing air flows and large force, and has an especially obvious effect of blowing away the flying cotton wools at holes. The blowing mechanisms process the flying cotton wools of a plurality of parts in time to improve the spinning quality of the circular weft knitting machine, and reduce the uppermost pollutant sources of the circular weft knitting machine and the main surrounding environment.

Owner:吴江天龙针织有限公司

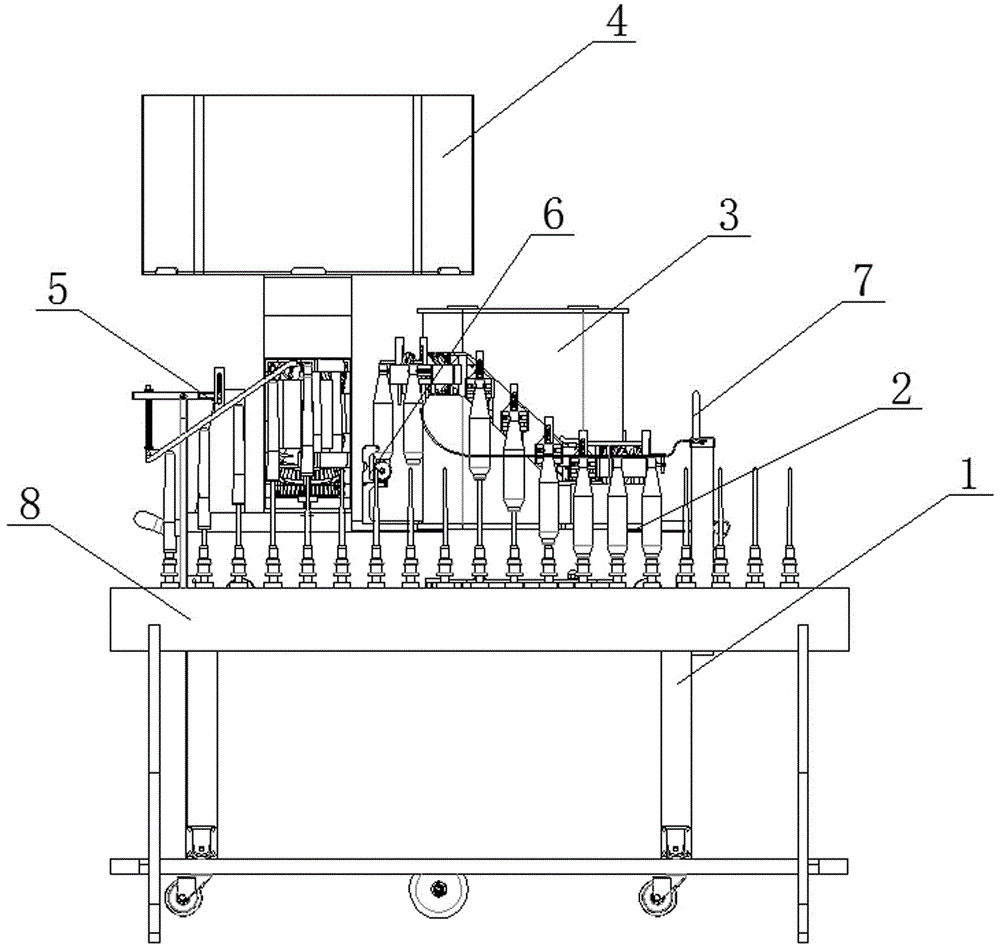

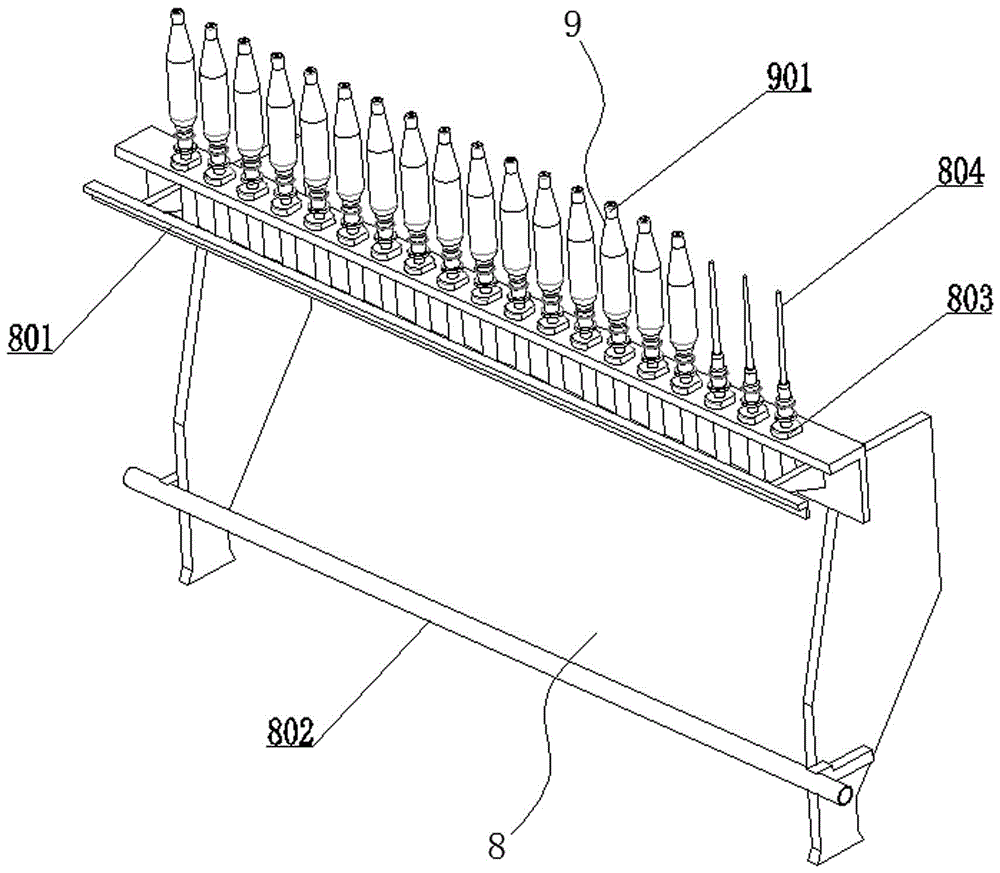

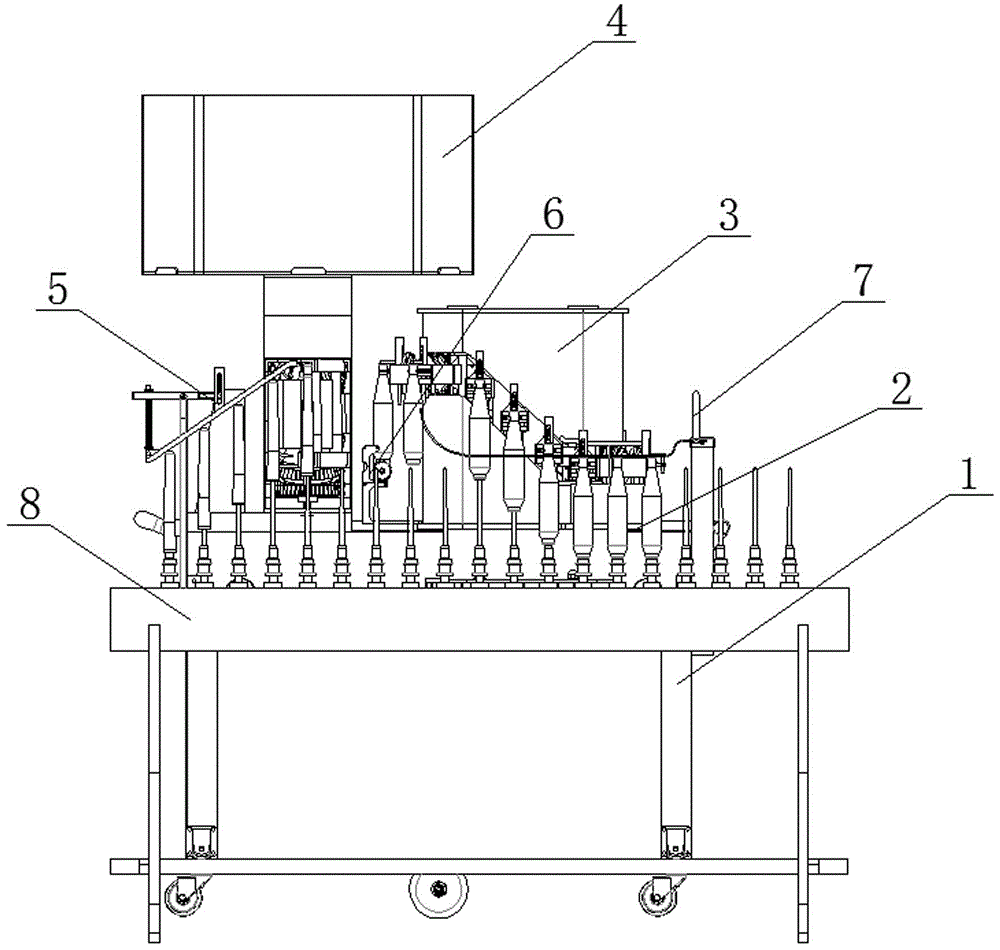

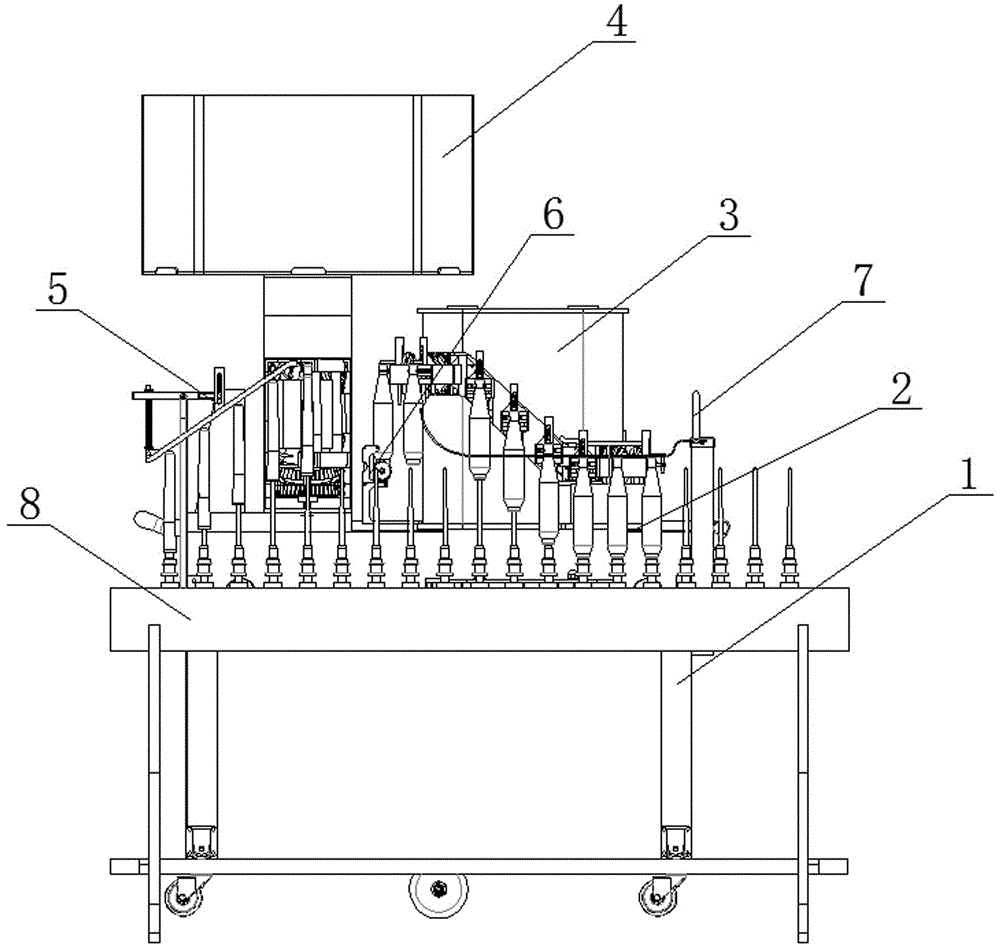

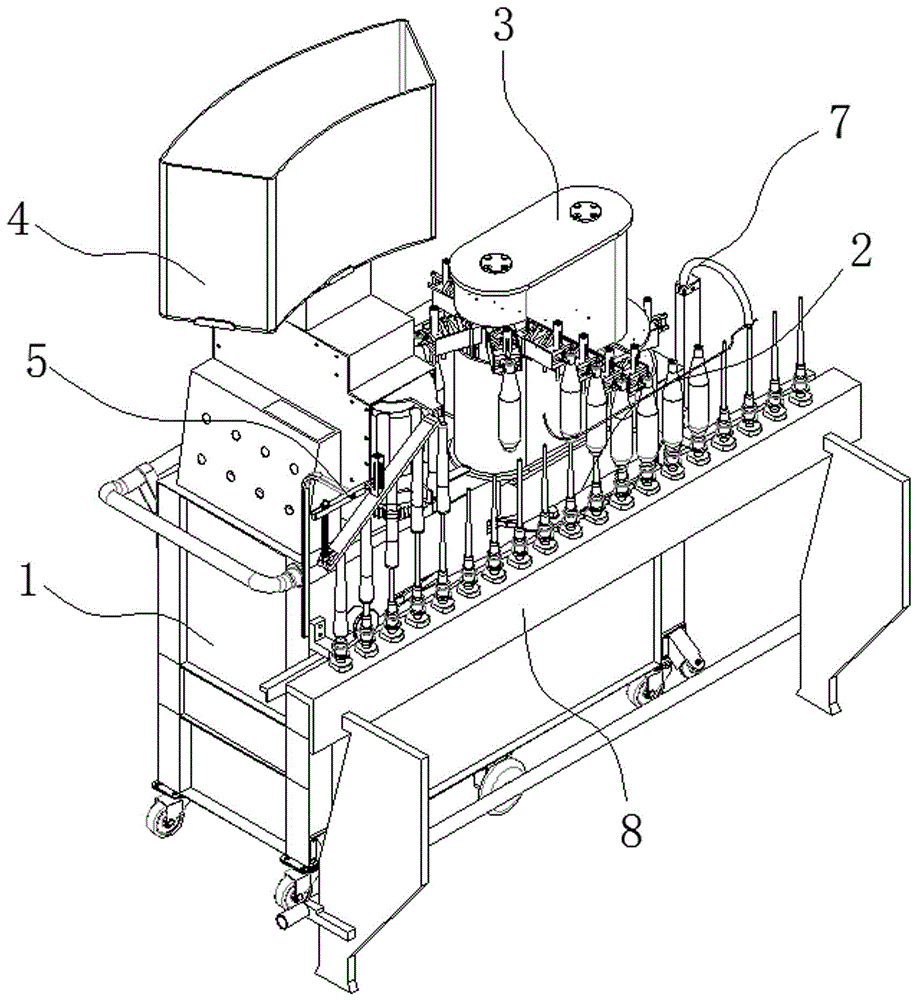

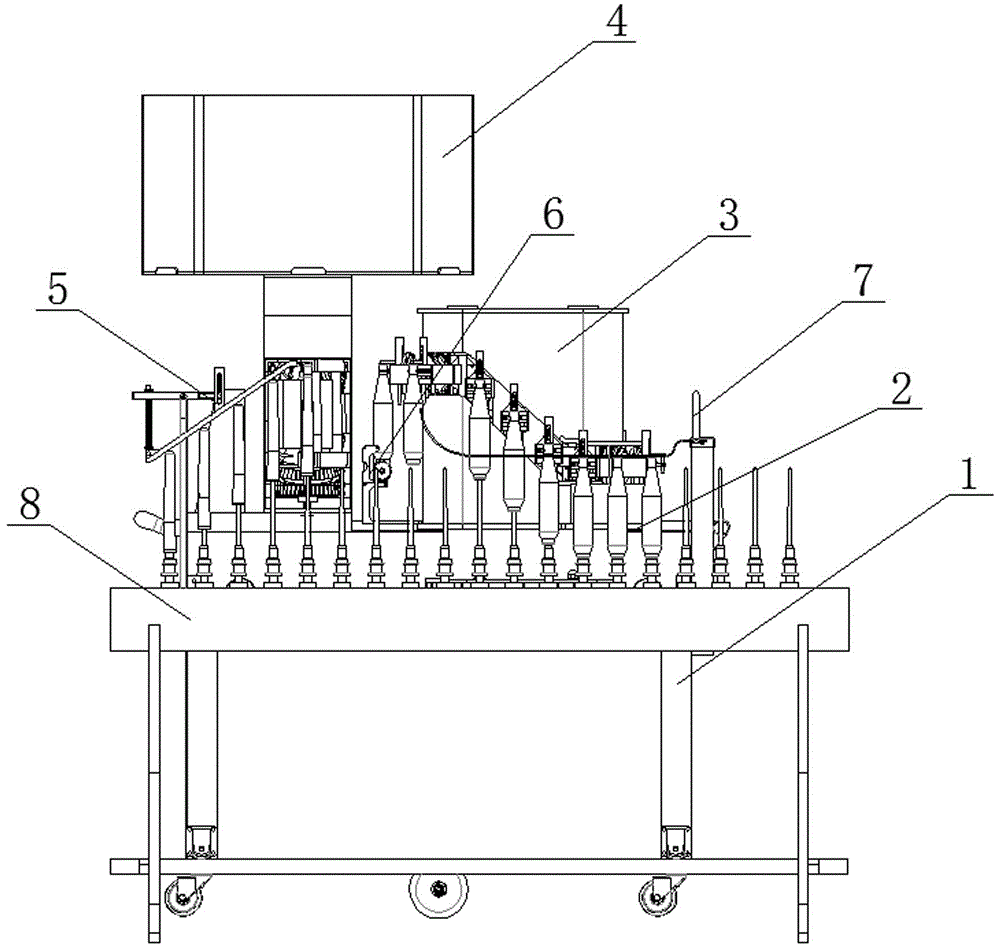

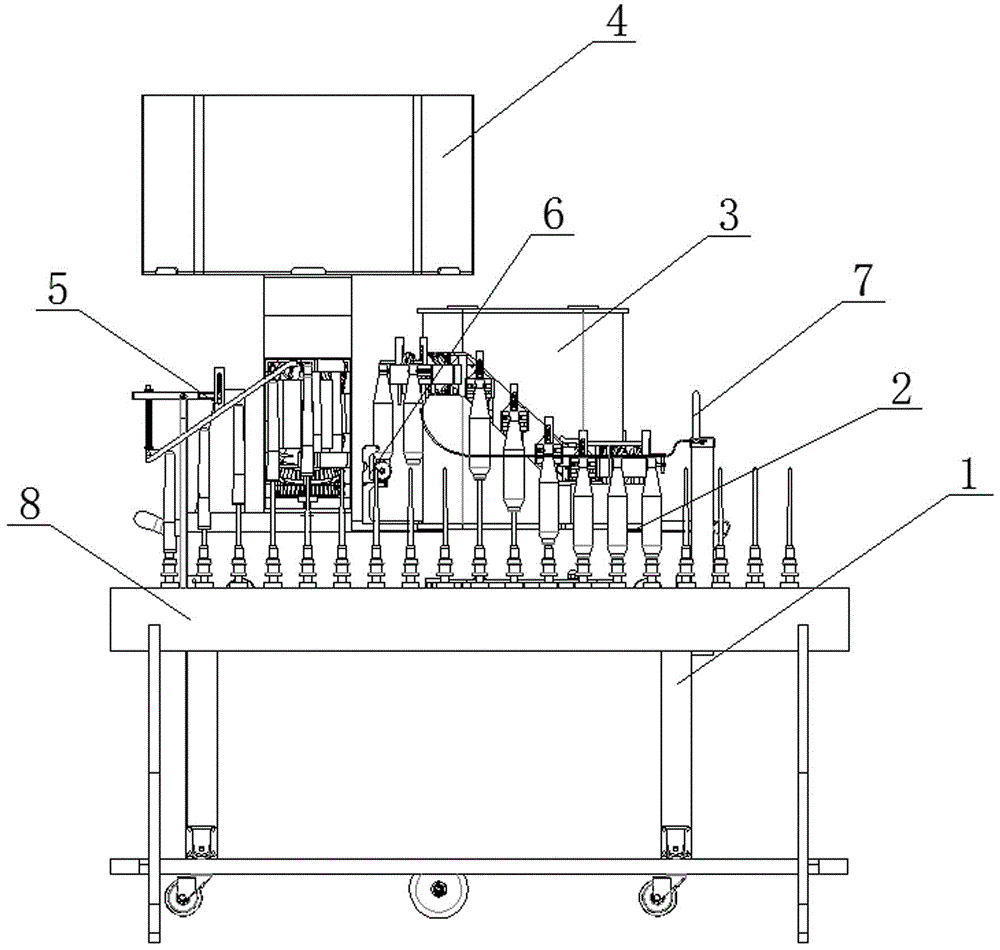

Worsted doffing machine

The invention relates to a worsted doffing machine. The worsted doffing machine comprises a rack moving trolley, an electrical equipment control box, an inserting and drawing tube positioning power device, a tube drawing device, a pipe inserting device, a yarn pressing device, a chopping composite yarn cutting device and a pipe pressing device. After corresponding, vertical and parallel positioning with a fine spinning machine spindle blade inserting and drawing station is completed on a trolley box through a spindle pitch positioning device, a walking support device and a walking parallel positioning device, a trolley walking driving device is driven to travel along an upper creel and a lower creel of a fine spinning machine, by combining the condition that a crawler-type positioning driving belt is meshed with each ingot phase of the fine spinning machine, feeding is conducted along a fine spinning machine track, and meanwhile integrated operation of tube drawing, tube inserting, yarn pressing, yarn cutting and tube pressing corresponding to the yarn pressing device, the tube drawing device, the chopping composite yarn cutting device, the tube inserting device and the tube pressing device corresponding to each spindle blade is accurately controlled.

Owner:荣德明

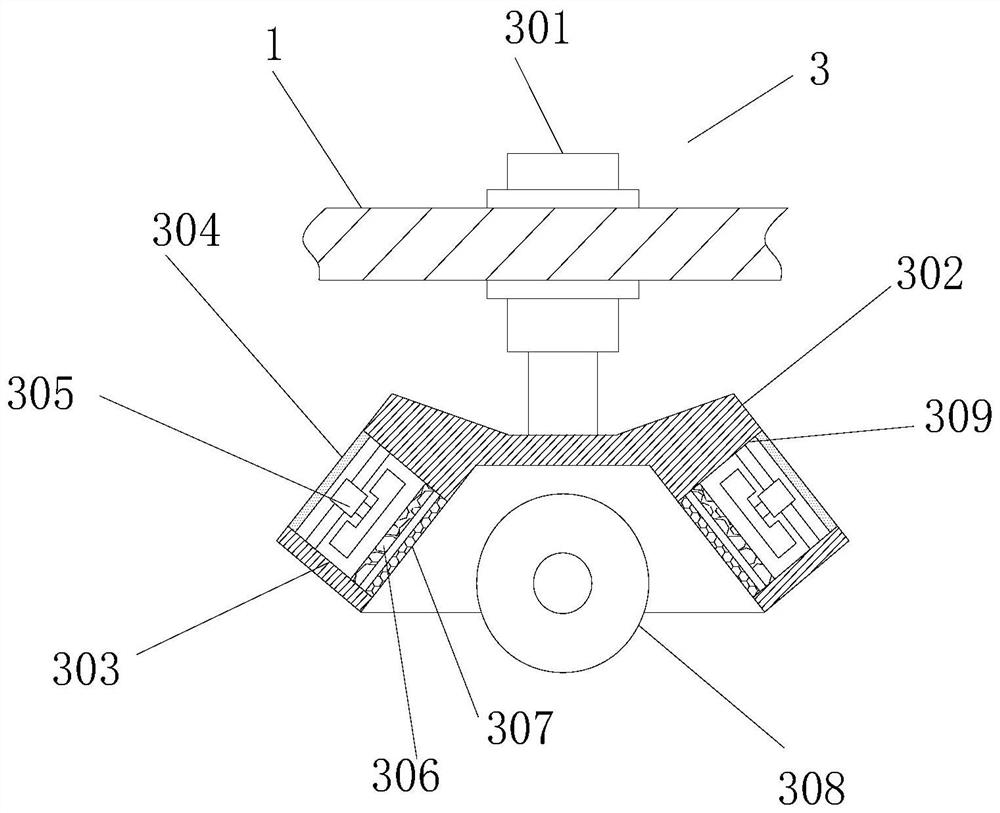

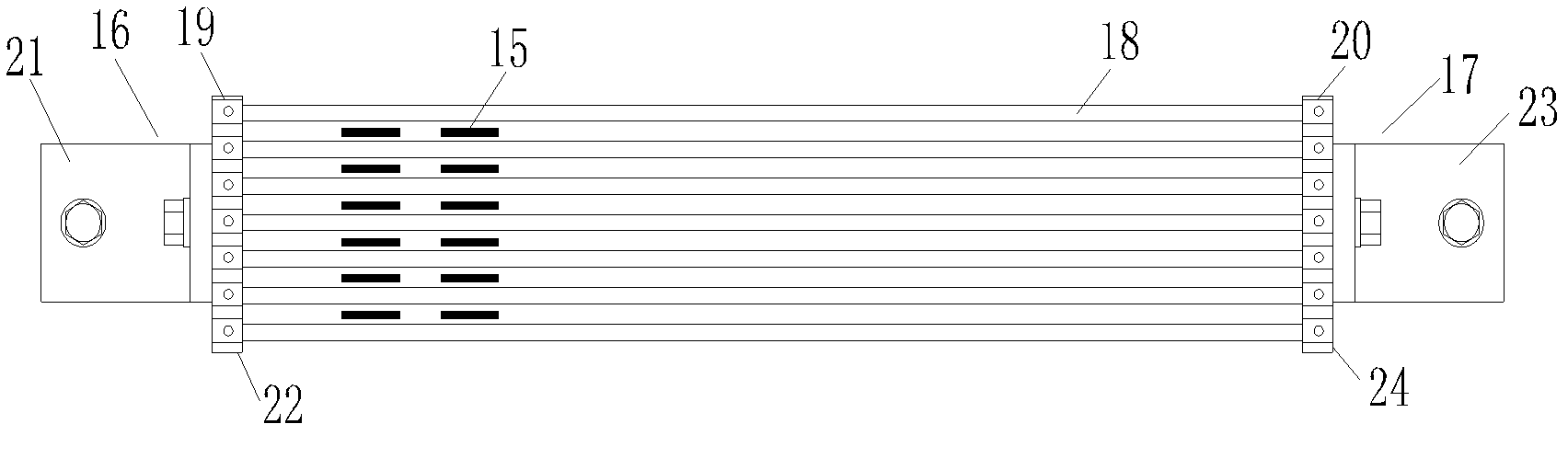

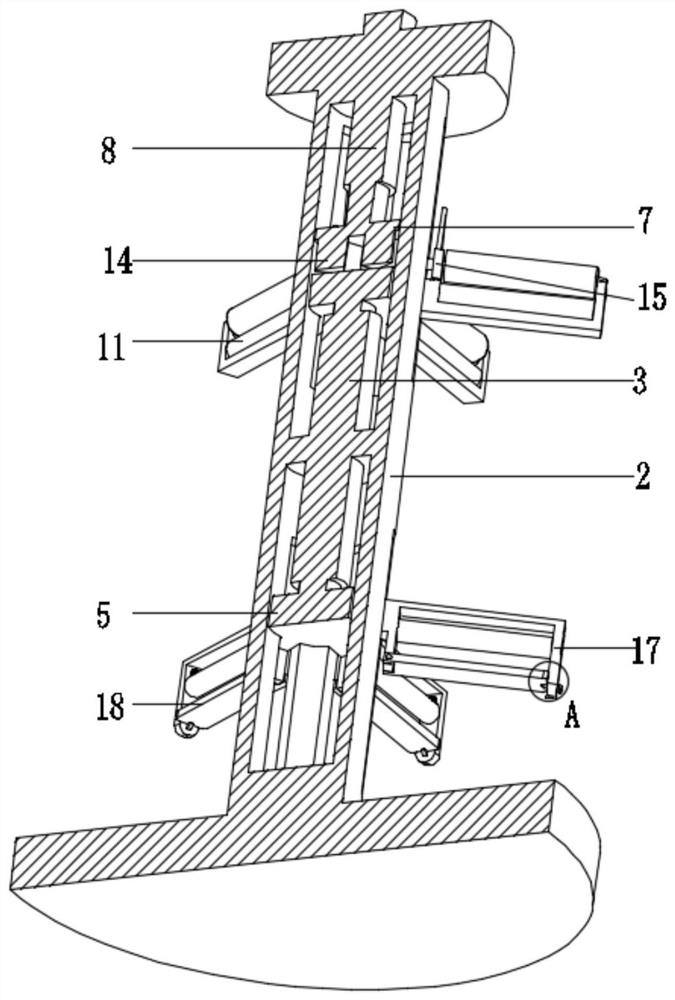

Tube drawing device of spinning doffer

The invention relates to a tube drawing device of a spinning doffer. The tube drawing device comprises a tube drawing frame assembly, a tube drawing power transmission assembly and a mechanical arm grabbing and interlocking force eliminating assembly. The tube drawing device has the advantages that the whole tube drawing process adopts a pure mechanical mode, each working node is reliable in operation action, accurate in beat, small in size and lightweight, and transformation of an existing spinning frame structure is not needed; the tube drawing device is small in power load, fast tube drawing using a single motor or using manual trolley pushing without a motor can be performed, and damage-free doffing of bobbins and spindles can be achieved.

Owner:荣德明

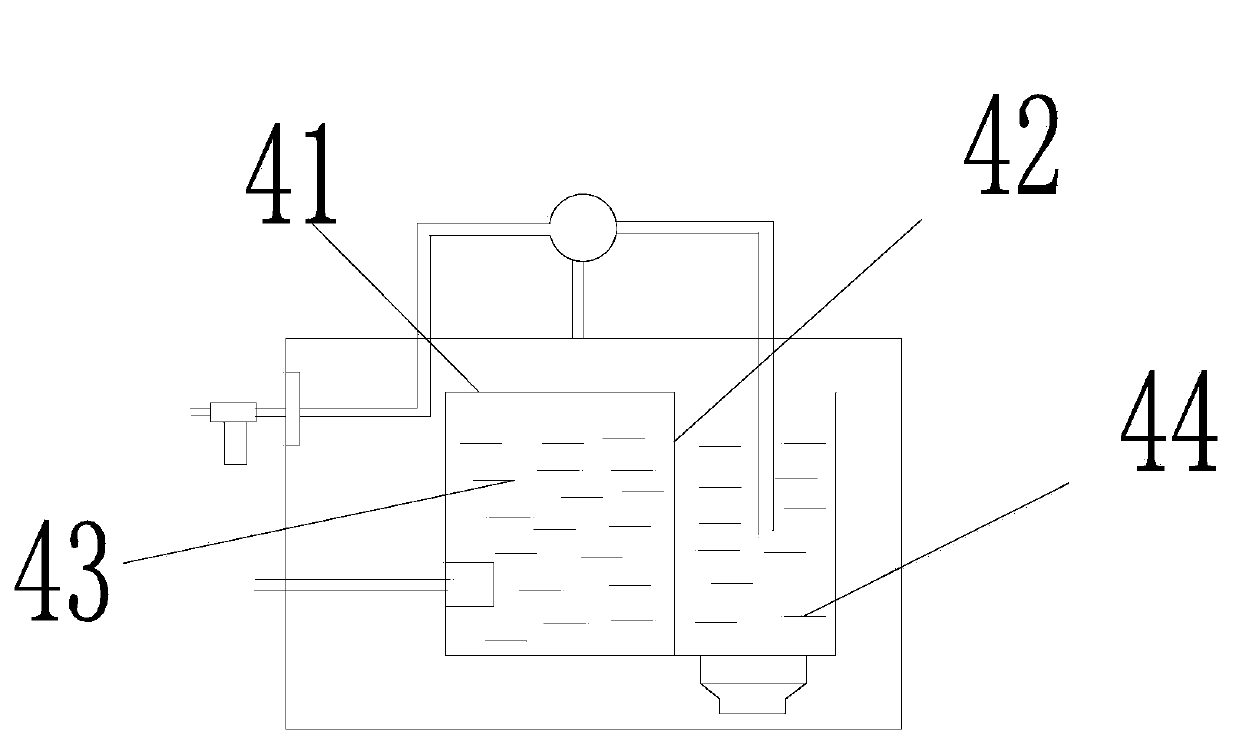

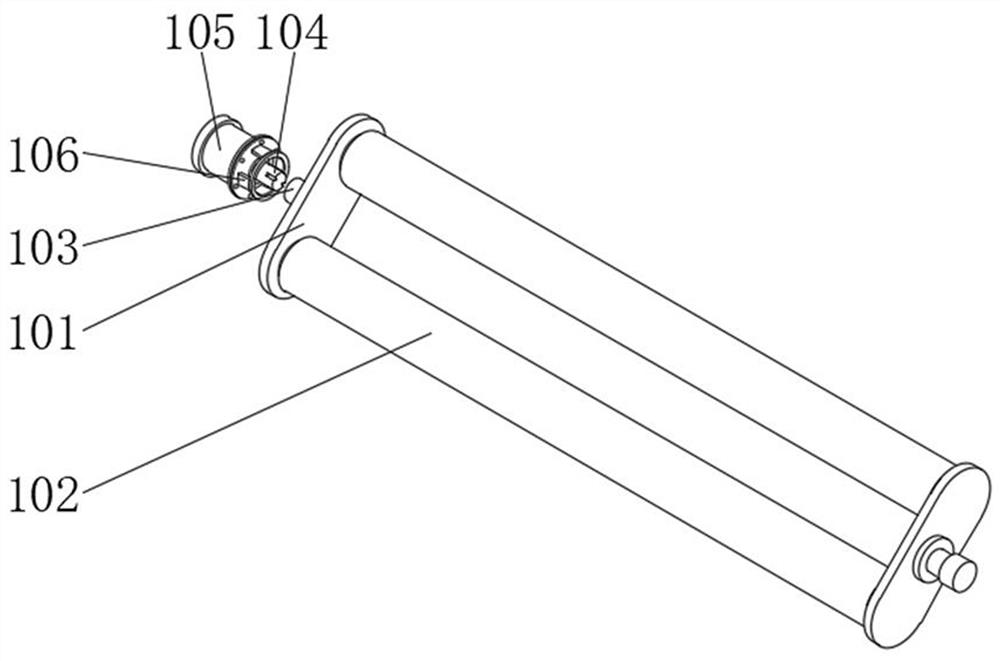

Textile roving frame flyer

The invention discloses a textile roving frame flyer which comprises a rotating shaft, a spindle shell, a yarn guiding block, a humidifier and an inclined through hole. The rotating shaft is fixedly connected with the spindle shell, the humidifier comprises a water tank, the water tank is divided into a water storage tank and a humidification water tank through a partition plate in the water tank, the partition plate is provided with a water supplementing opening, the water storage tank is communicated with a water inlet pipe, a heater is installed at the bottom of the humidification water tank, a water sucking pipe is arranged on the upper portion of the humidification water tank to be connected with a spray head, the air humidifier is further provided with an air inlet pipe, and the air inlet pipe is connected with the spray head. The roving frame flyer is simple, compact and reasonable in structure, convenient and rapid to assemble and reliable to connect, abrasion resistance of the flyer is improved, the shortcoming that a yarn outlet is abraded easily is overcome, the roving end breakage rate is low, the high-speed performance is good, flying fibers are not generated easily, spinnability and weaving quality are improved, working reliability of a roving frame is greatly improved, and the textile roving frame flyer is easy to use and popularize.

Owner:张家港市天江精密模具制造有限公司

Mechanical hand grabbing and interlocking force eliminating combined device of spinning doffer

The invention relates to a mechanical hand grabbing and interlocking force eliminating combined device of a spinning doffer. The mechanical hand grabbing and interlocking force eliminating combined device is characterized by comprising a mechanical hand grabbing device and an interlocking force eliminating device, a pure mechanical mode is adopted in the whole bobbin drawing process, operation of all worknodes is reliable in action and accurate in rhythm, the combined device is small in size and light in weight, and an existing spinning structure does not need to be improved. Power load is small, a cart can be pushed with a single motor or pushed manually without a motor to fast draw a bobbin, and doffing is achieved without damage to the bobbin or a spindle.

Owner:荣德明

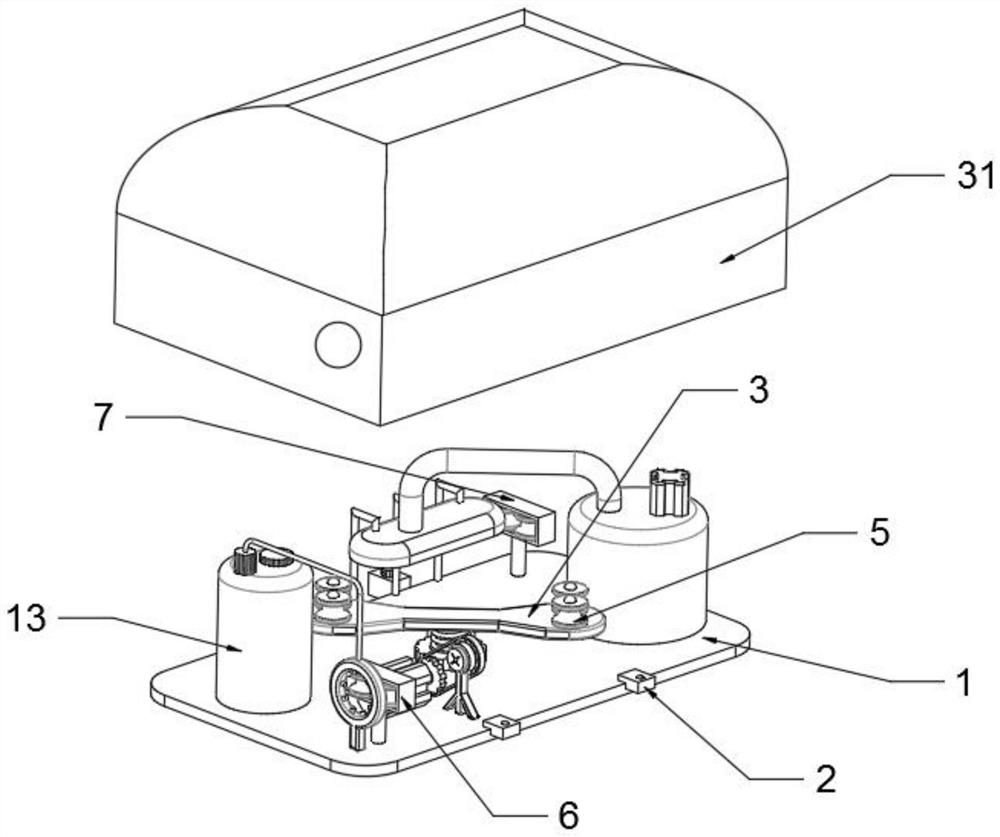

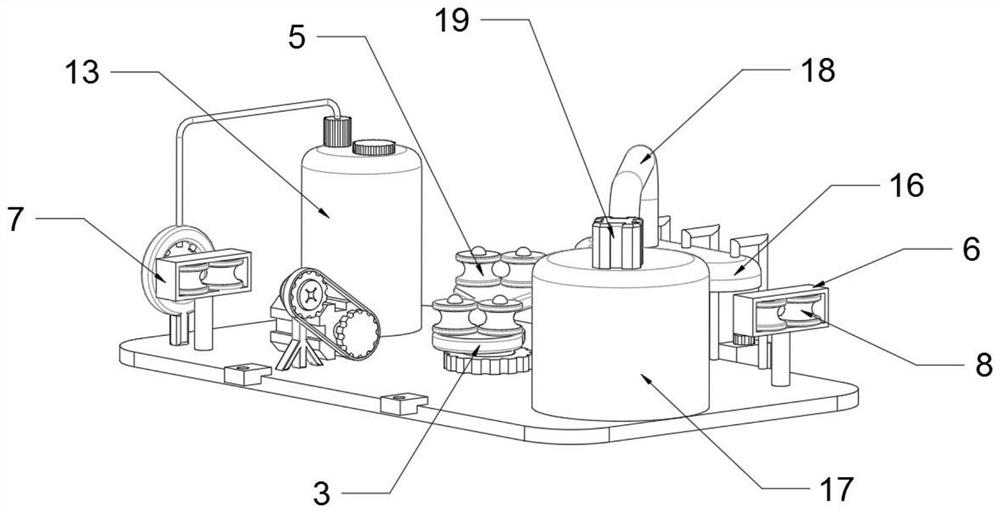

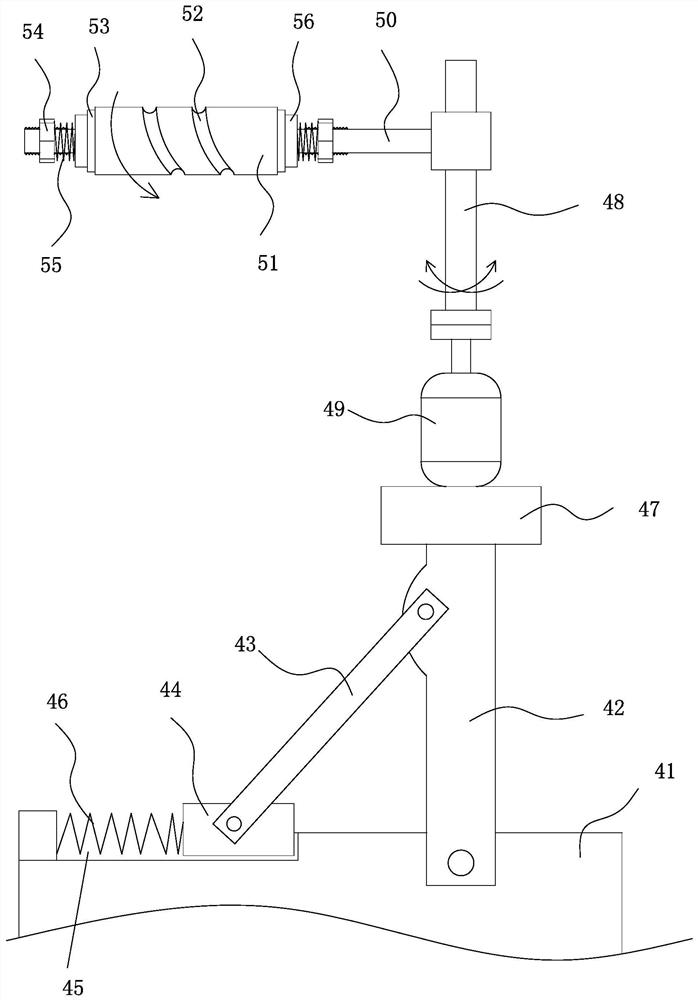

Pipe inserting and pulling positioning power device of fine-spinning doffing machine

The invention relates to a pipe inserting and pulling positioning power device of a fine-spinning servo doffing machine. The pipe inserting and pulling positioning power device comprises a positioning movable connecting base, a curved rolling wheel bearing, a crawler-type positioning transmission belt, a pipe pulling power belt wheel, a pipe pulling power main transmission shaft, a pipe inserting power driving belt wheel, a tooth-shaped transmission belt, a pipe inserting power driven belt wheel, a pipe inserting power transmission shaft, a crawler-type positioning linear motor, a crawler-type positioning linear motor fixing seat, a crawler-type positioning linear motor driving fixing seat, a linear sliding rod, a linear sliding rod fixing seat and a linear sliding rod bearing; the crawler-type positioning transmission belt is engaged with each spindle of a fine spinning machine; and the device is used for feeding along a rail of the fine spinning machine and subsequent pipe inserting and pulling power is provided for each corresponding spindle rod through accurate control.

Owner:荣德明

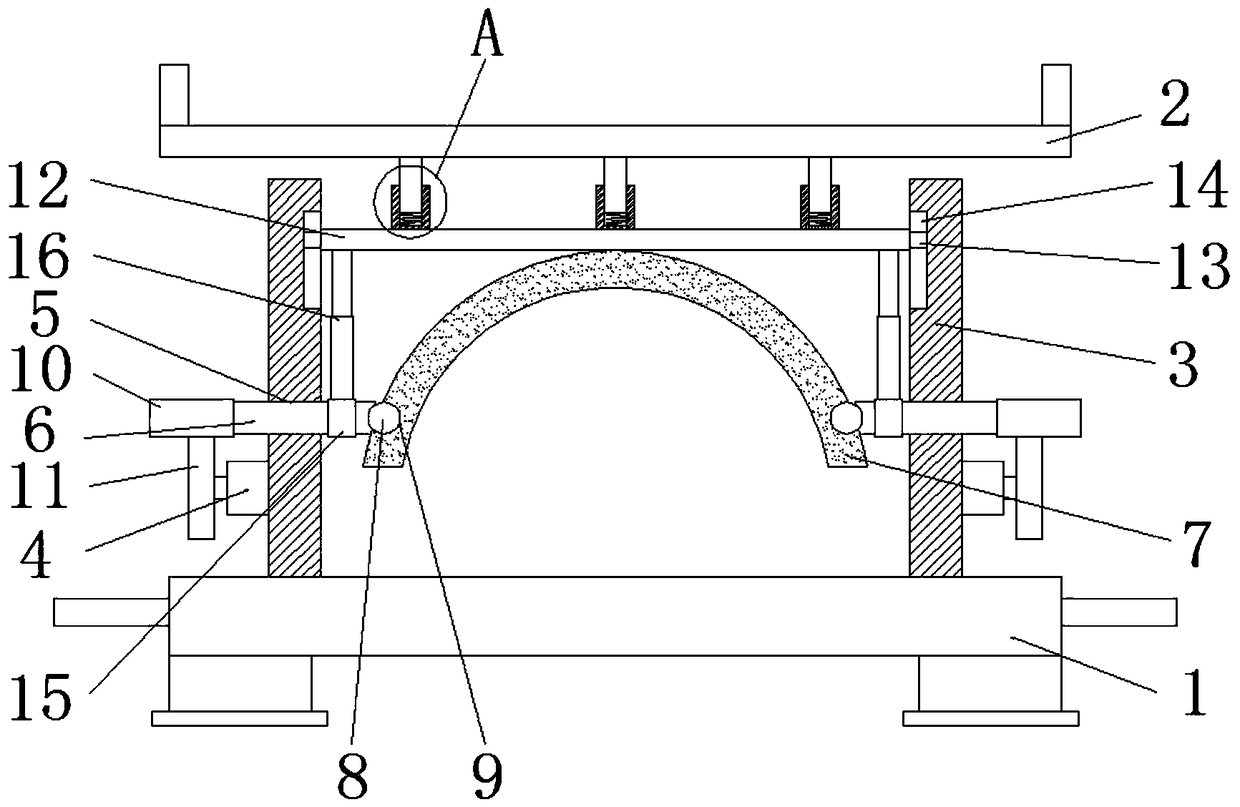

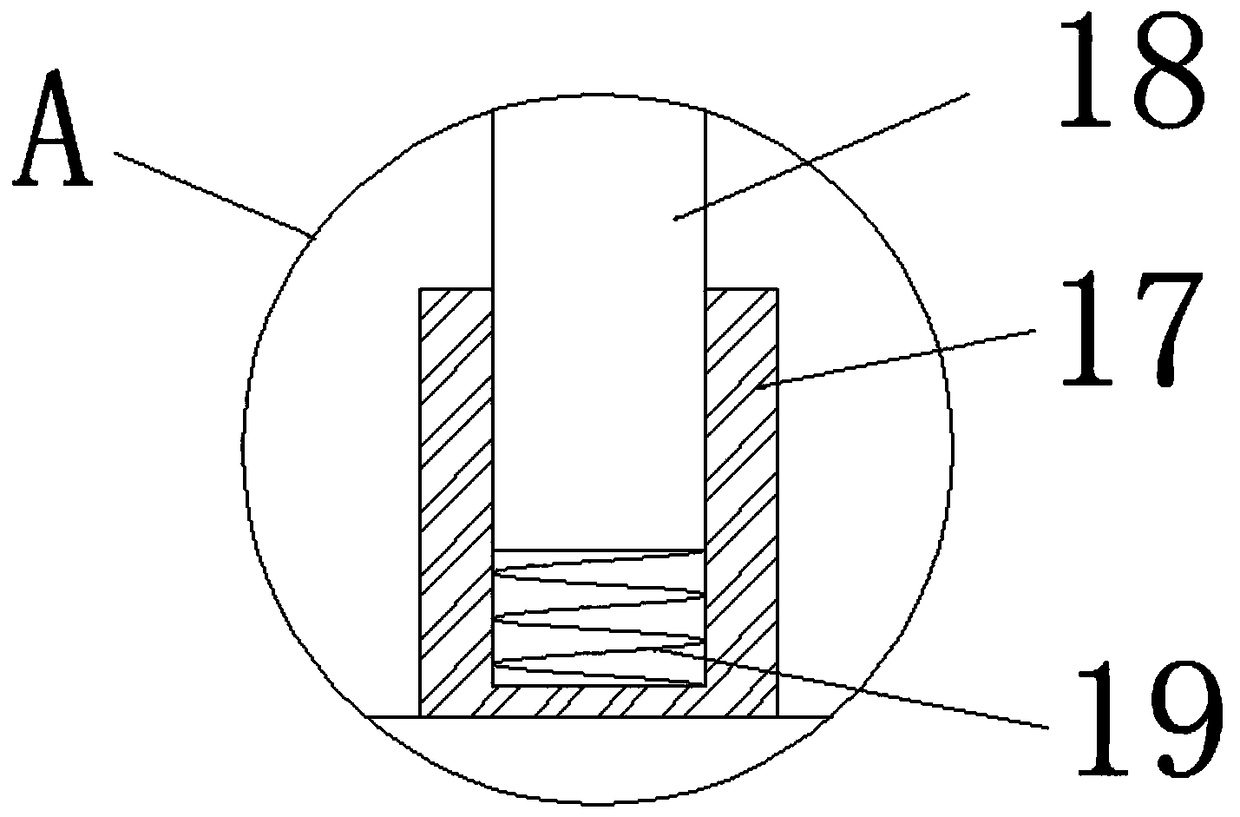

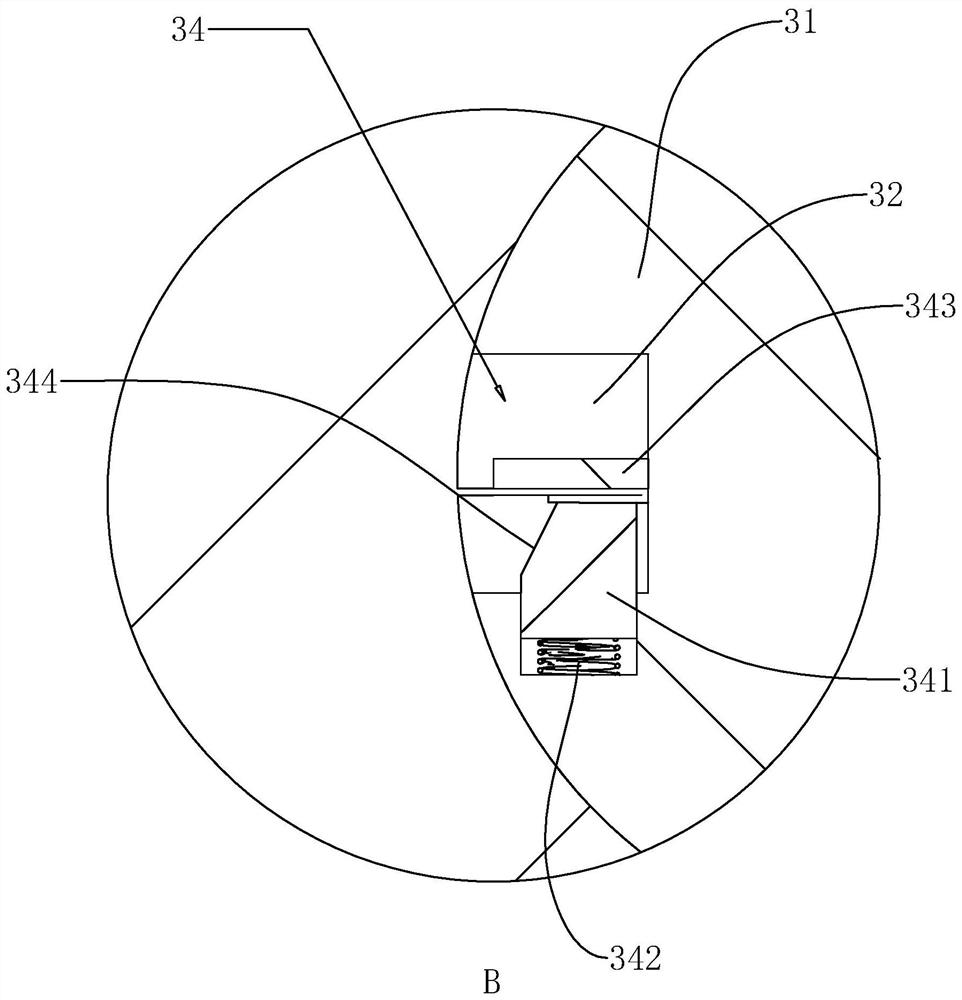

Damping adjusting seat for textile machinery

InactiveCN109163195AImprove shock absorptionImprove textile qualityNon-rotating vibration suppressionLeaf springsDrive motorEngineering

The invention discloses a damping adjusting seat for textile machinery. The damping adjusting seat comprises a bottom plate and a placing plate, wherein baffles are vertically and fixedly connected toboth sides of the top of the bottom plate, driving motors are fixedly connected to the opposite sides of the two baffles, screw holes are horizontally formed in the baffles, threaded rods are in threaded connection to the interiors of the screw holes, a curved spring plate is installed between the two threaded rods, one end of the threaded rods penetrate through the screw holes, toothed columns are fixedly connected to one end of the threaded rods on the outer sides of the baffles, gears which are engaged with the toothed columns are fixedly connected to output shafts of the driving motors, asupport plate is horizontally and movably connected between the two baffles, the support plate is located above the curved spring plate, a plurality of sleeves are fixedly connected to the top of thesupport plate, insertion plates which are matched with the sleeves are fixedly connected to the bottom of the placing plate, and a plurality of damping springs are fixedly connected to the bottoms ofthe inner walls of the sleeves. The damping adjusting seat has the advantages of high damping capacity and convenience in adjusting the height and the damping strength, and the textile quality is increased.

Owner:刘四凤

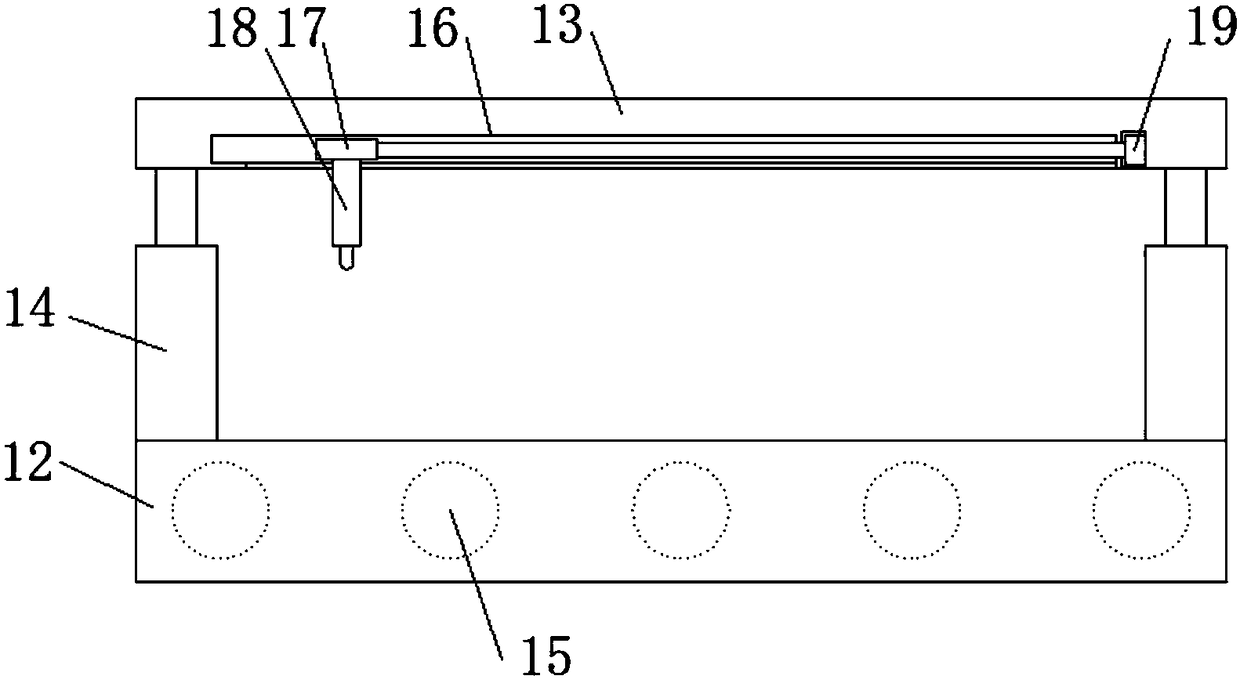

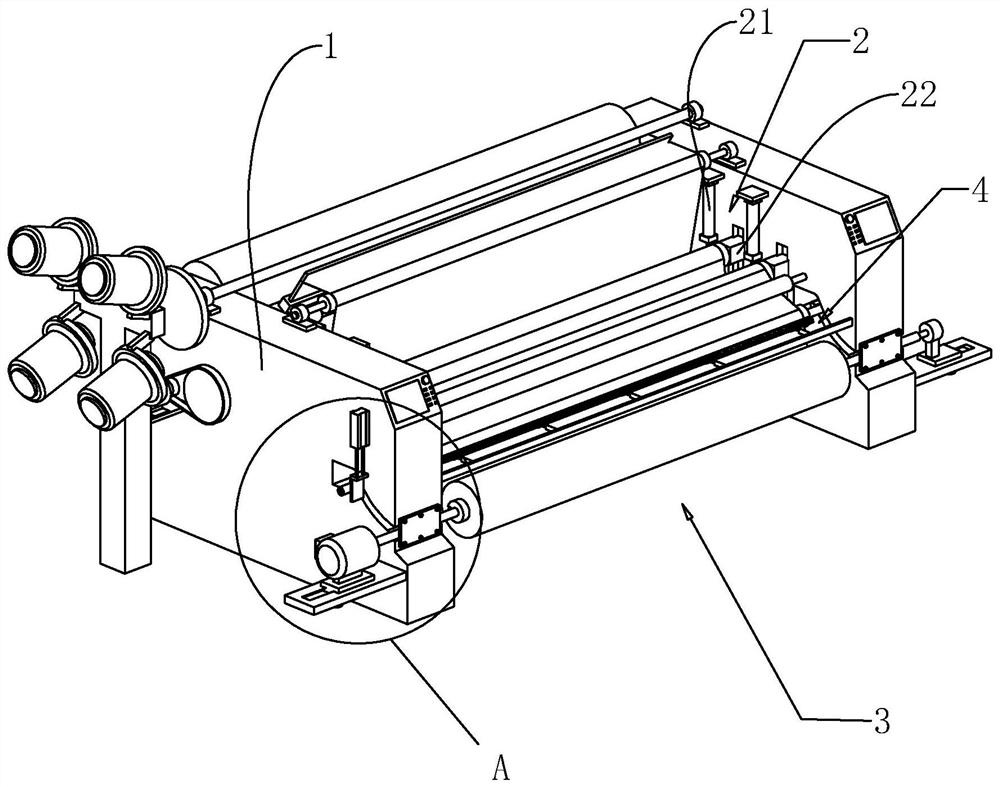

Air jet loom for high-temperature-resistant fabric and using method thereof

ActiveCN111826780AImprove work efficiencyCut faster and betterLoomsAuxillary apparatusAir-jet loomEngineering

The invention relates to an air jet loom for high-temperature-resistant fabric and a using method of the air jet loom. The air jet loom comprises a machine body. A winding mechanism is arranged at oneend of the machine body and comprises a main winding roller and an auxiliary winding roller. A main clamping assembly is arranged on the main winding roller, and an auxiliary clamping assembly is arranged on the auxiliary winding roller. A cutting mechanism is arranged on the side, exactly opposite to the auxiliary clamping roller, of the machine body. Sliding grooves which penetrate through theside wall of the machine body are formed in the two sides of the interior of the machine body, and the two ends of the main winding roller and the two ends of the auxiliary winding roller are arrangedin the sliding grooves and detachably connected with the machine body. When the quantity of the fabric on the main winding roller is equal to a certain quantity, the fabric is cut by the cutting mechanism, the main winding roller and the fabric are replaced, the bottom end of the remaining fabric passes through the auxiliary clamping assembly and then is clamped on the auxiliary winding roller, the fabric is wound through the auxiliary winding roller, the auxiliary winding roller slides to the main winding roller through the sliding grooves and becomes a new main winding roller, and the process that the winding rollers are replaced as non-stop operation is conducted is accomplished. The air jet loom has the effect of improving the working efficiency of the air jet loom.

Owner:杭州明华纺织有限公司

Fine spinning doffer imbedding force eliminating device

The invention relates to a fine spinning doffer imbedding force eliminating device. The imbedding force eliminating device comprises a manipulator upper positioning plate, an impact rod fixing plate, an impact rod, a compression spring ejection rod, a spring sleeve and an impact compression spring. A pure mechanical mode is adopted in the whole process, working nodes are reliable in motion action, accurate in tact, small in size and light in weight, and transformation of an existing fine spinning structure is not needed. The power load is small, a trolley can be manually pushed to rapidly pull a bobbin in a single-motor or motor-free mode, and doffing without bobbin or spindle damage is achieved.

Owner:荣德明

Textile skein fluffing device

InactiveCN112030301ALarge capacitySave spaceDispersed particle filtrationFibre cleaning/openingTextile technologyDust control

The invention discloses a textile skein fluffing device in the technical field of textiles. The textile skein fluffing device comprises a fluffing base and a fluffing column, wherein a middle air cylinder is fixedly mounted in the middle of the fluffing column, multiple groups of sliding chutes are formed in the outer wall of the fluffing column, fluffing disks are fixedly connected to the two ends of the middle air cylinder correspondingly, and extension frames are fixedly connected to the side wall of each fluffing disk correspondingly; each extension frame penetrates through the corresponding sliding chute to be in sliding fit with the corresponding sliding chute; a reversing assembly is arranged at the top of the extension frame which is located at the upper part, and a hanging assembly is arranged at the bottom of the extension frame which is located at the lower part; the reversing assembly comprises a mounting disk slidably connected into the fluffing column, a pressing air cylinder is fixedly connected between the top of the mounting disc and the fluffing column, and multiple groups of reversing rollers are rotationally arranged at the bottom of the mounting disk; the fluffing column is rotationally connected to the top of the fluffing base, a shield is fixedly connected to the top of the fluffing base, and a dust removal assembly is arranged at the top of the shield. The textile skein fluffing device is hung in a vertical direction, so that the capacity is large, and space is saved; human resources are not used, and multiple reels of skein can be fluffed in one time, so that the efficiency is improved, and time is saved; and impurities are removed during fluffing, so that use space is protected and clean.

Owner:秦明鸿

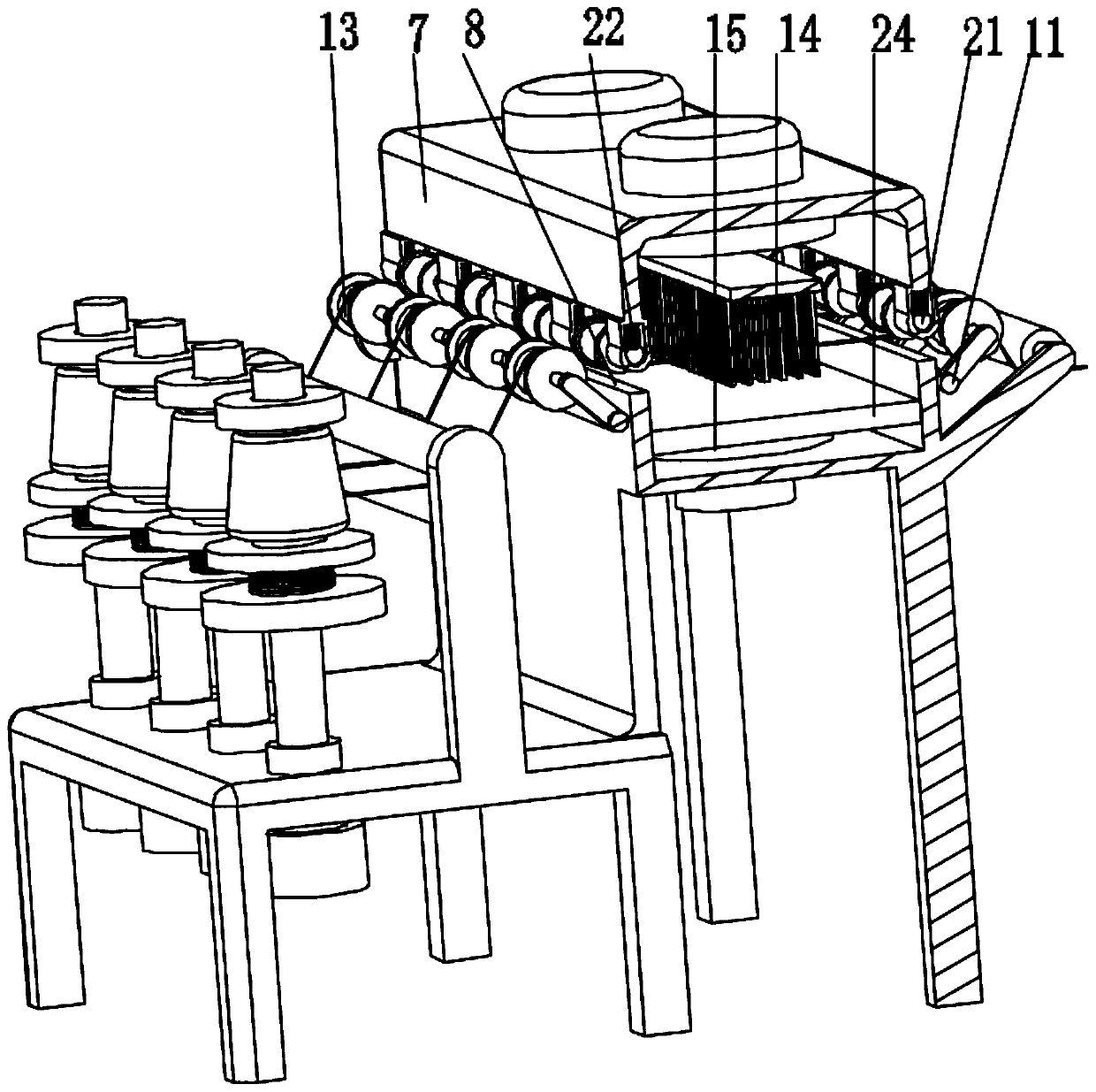

Manipulator device of fine-spinning doffing machine

The invention relates to a manipulator device of a fine-spinning doffing machine. The manipulator device comprises a manipulator sliding block connection seat, a manipulator lower locating plate, a clamping force-bearing rod, a clamping linkage rod, a deflector rod retainer, a loosening force-bearing rod, a loosening linkage rod, a loosening push rod, a movable force arm, a clamping deflector rod, a loosening deflector rod, a supporting rod, a tension spring, a fixed force arm, a pressure spring, a first movable clamping claw and a second movable clamping claw. By the adoption of a pure mechanical mode, all working nodes are reliable in operation action, accurate in beat, small in size and light in weight, and the structure of the existing fine spinning machine is not needed to be transformed. Due to low power load, bobbins can be quickly pulled out with a single motor or by pushing a trolley manually without a motor, so that scatheless doffing of the bobbins and spindles is realized.

Owner:荣德明

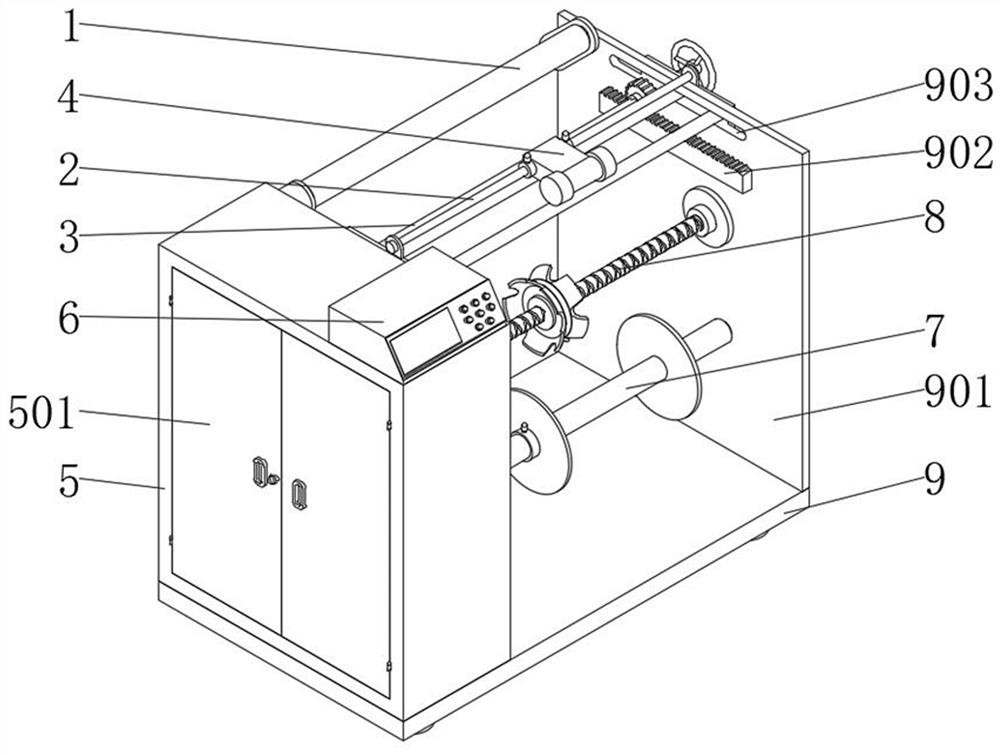

Winding device with high retentivity for spandex yarn production and processing

The invention discloses a winding device with high retentivity for spandex yarn production and processing. The winding device with high retentivity for spandex yarn production and processing comprises a tightness adjusting assembly, a mounting box, a yarn swinging assembly and a bottom plate, wherein the mounting box is mounted on one side, far away from a side plate, of the top of the bottom plate; the extending tightness adjusting assembly is mounted on one side of the interior of the mounting box; the yarn swinging assembly is mounted between the mounting box and the side plate; the yarn swinging assembly comprises a reciprocating lead screw; a reciprocating cycloid disc is mounted on the outer side of the reciprocating lead screw; and an extending winding assembly is mounted in the mounting box. According to the winding device with high retentivity for spandex yarn production and processing provided by the invention, through the tightness adjusting assembly, a tightness adjusting roller can be adjusted, the traction force of a spandex yarn can be adjusted, the tightness of the spandex yarn semi-surrounding the outer side of the tightness adjusting roller is adjusted, and the problems that the elastic spandex yarn is too loose and too tight during winding are effectively solved, so that the compactness of the spandex yarn during winding is ensured; and the spandex yarn can be driven to swing in a reciprocating mode through the yarn swinging assembly, so that the spandex yarn is evenly wound.

Owner:南通世纪纺织有限公司

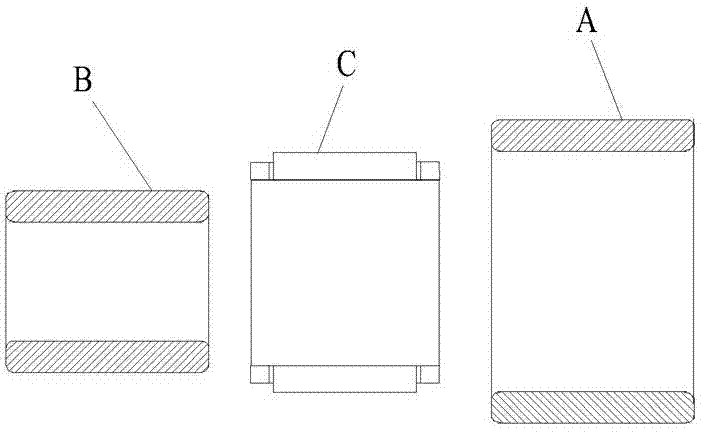

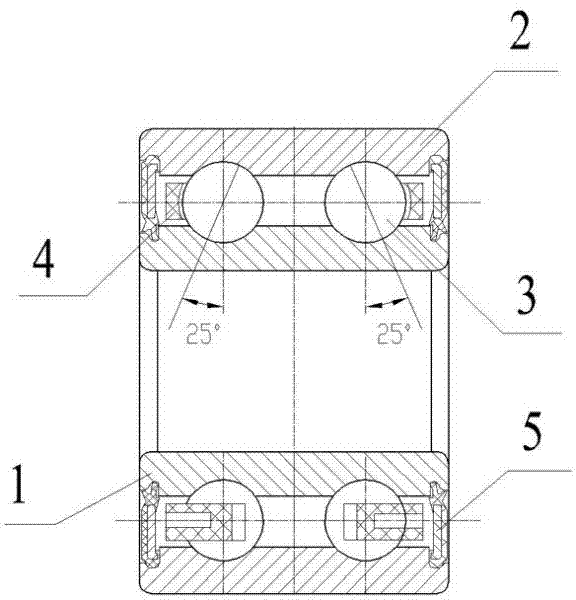

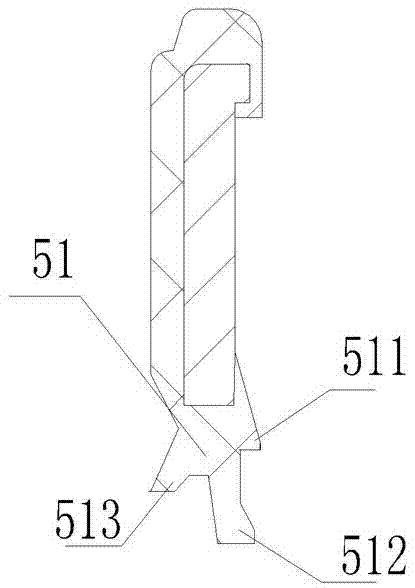

High-speed sealing integrated lower roller bearing

InactiveCN102518653ADoes not affect operationEasy to fixRolling contact bearingsDrafting machinesSteel ballRoller bearing

The invention discloses a high-speed sealing integrated lower roller bearing, comprising a bearing inner ring, a bearing outer ring, steel balls, a retainer and a dustproof seal ring, wherein the inner wall of the bearing outer ring is provided with multiple channels, the outer wall of the bearing inner ring is correspondingly provided with multiple channels, thus multiple roller paths are formed; each roller path clamps multiple steel balls, the steel balls are equispaced from each other by the retainer, and the multiple roller paths are symmetrically arranged along the direction of an axial symmetric line of the bearing; and the outer wall of the dustproof seal ring and the outer side of the inner wall of the bearing outer ring are tightly matched, and the inner wall of the dustproof seal ring and the outer side of the outer wall of the bearing inner ring are in clearance fit. By adopting the technical scheme of the invention, frictional resistance and noise can be greatly reduced, and rotating speed can be greatly improved; meanwhile, oil is prevented from leaking, oil is not required to be added for a long time, and dust can be prevented from entering the high-speed sealing integrated lower roller bearing.

Owner:浙江博盟精工机械有限公司

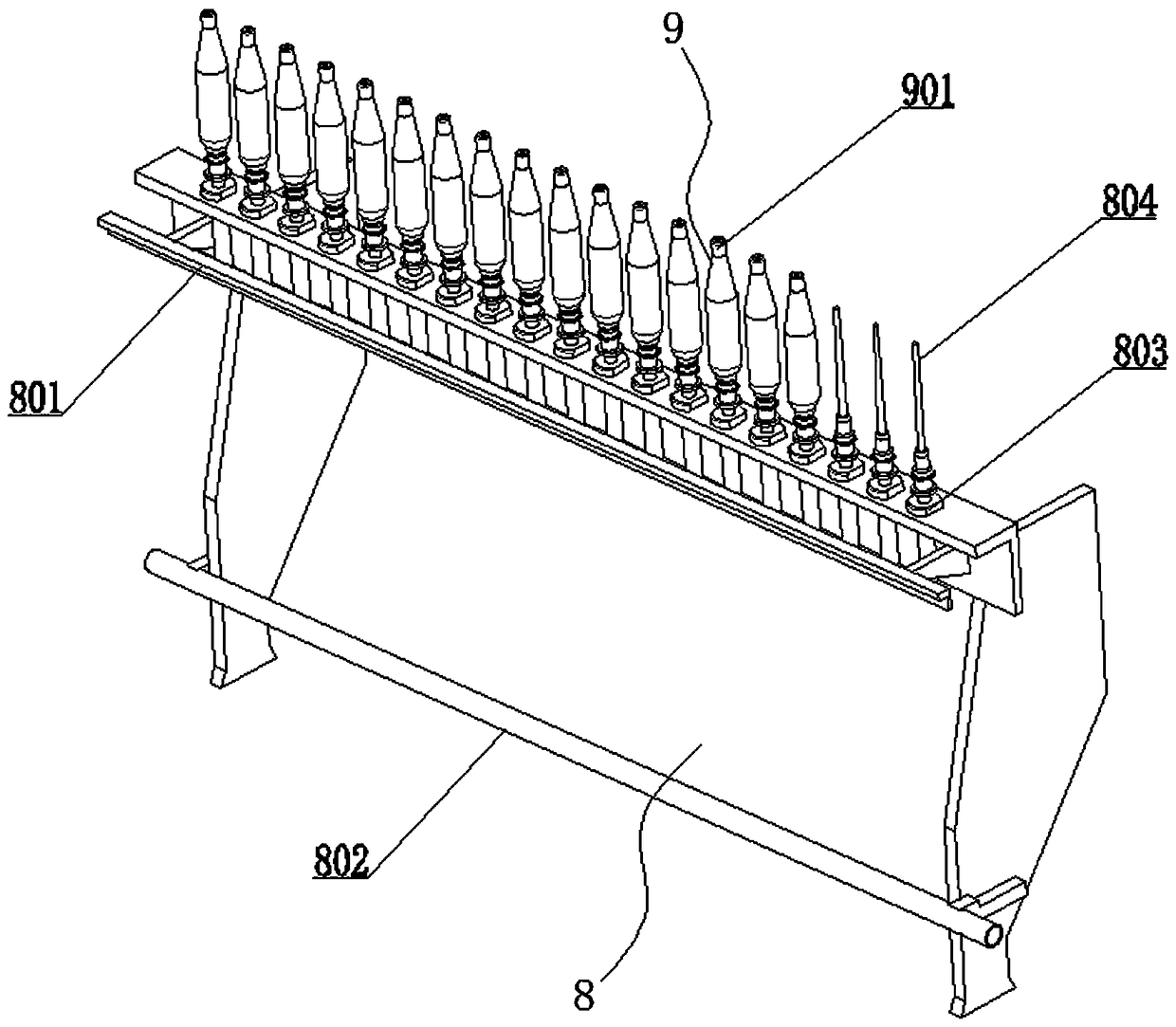

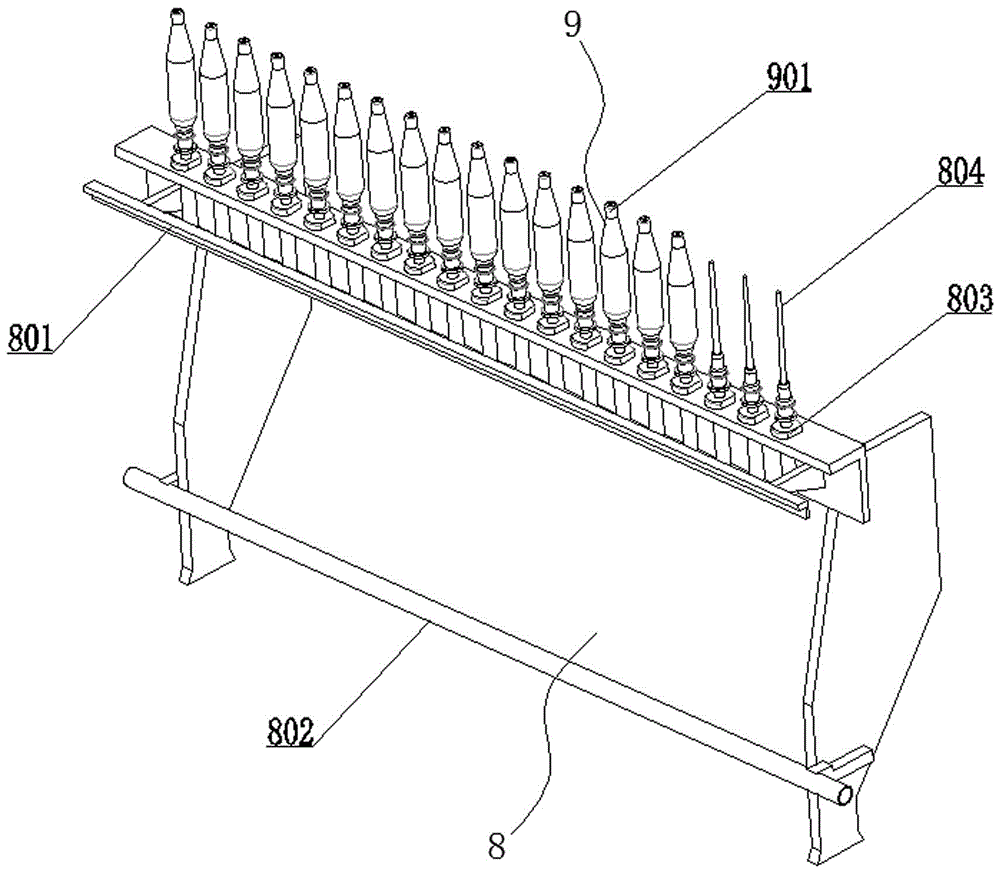

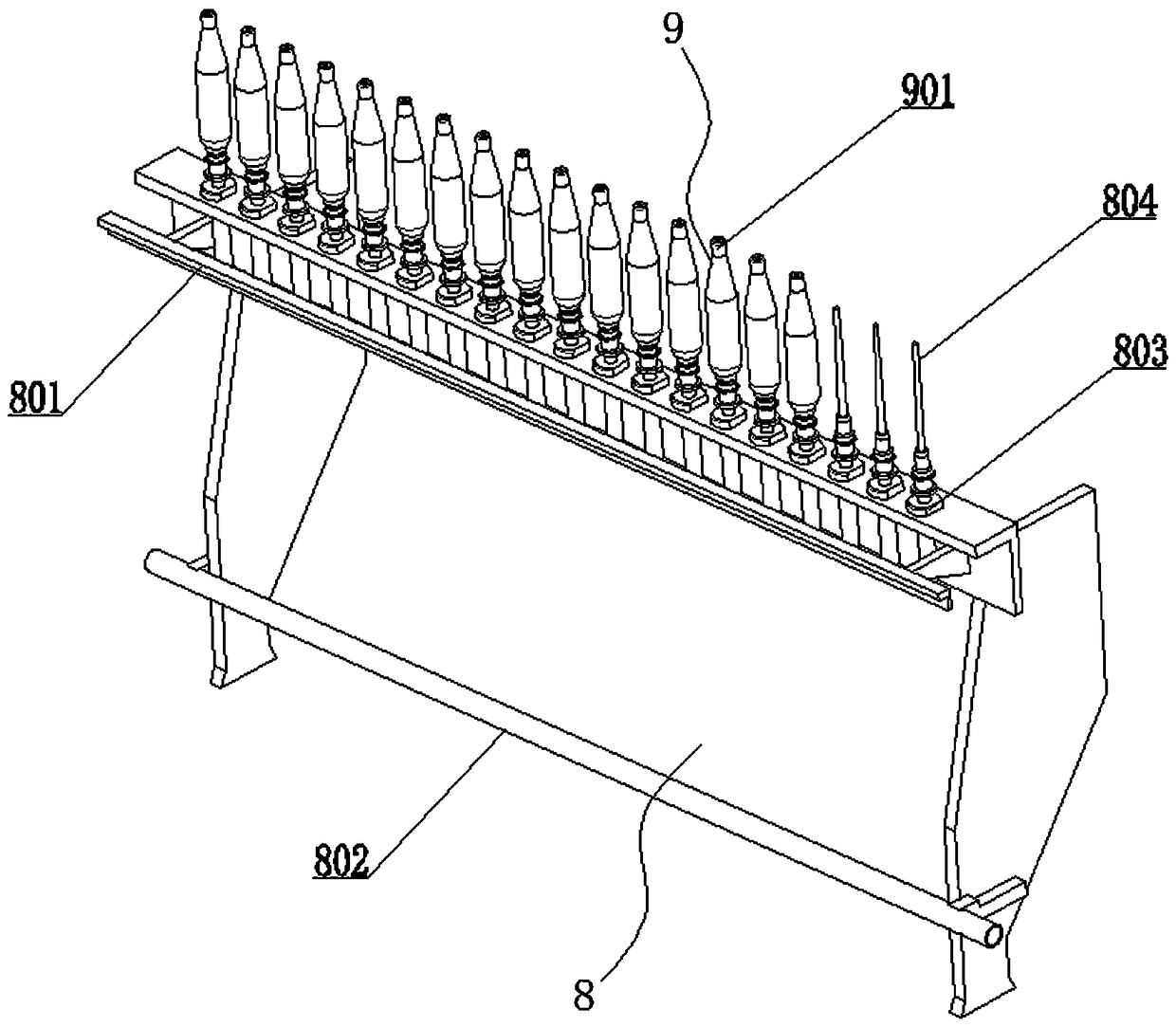

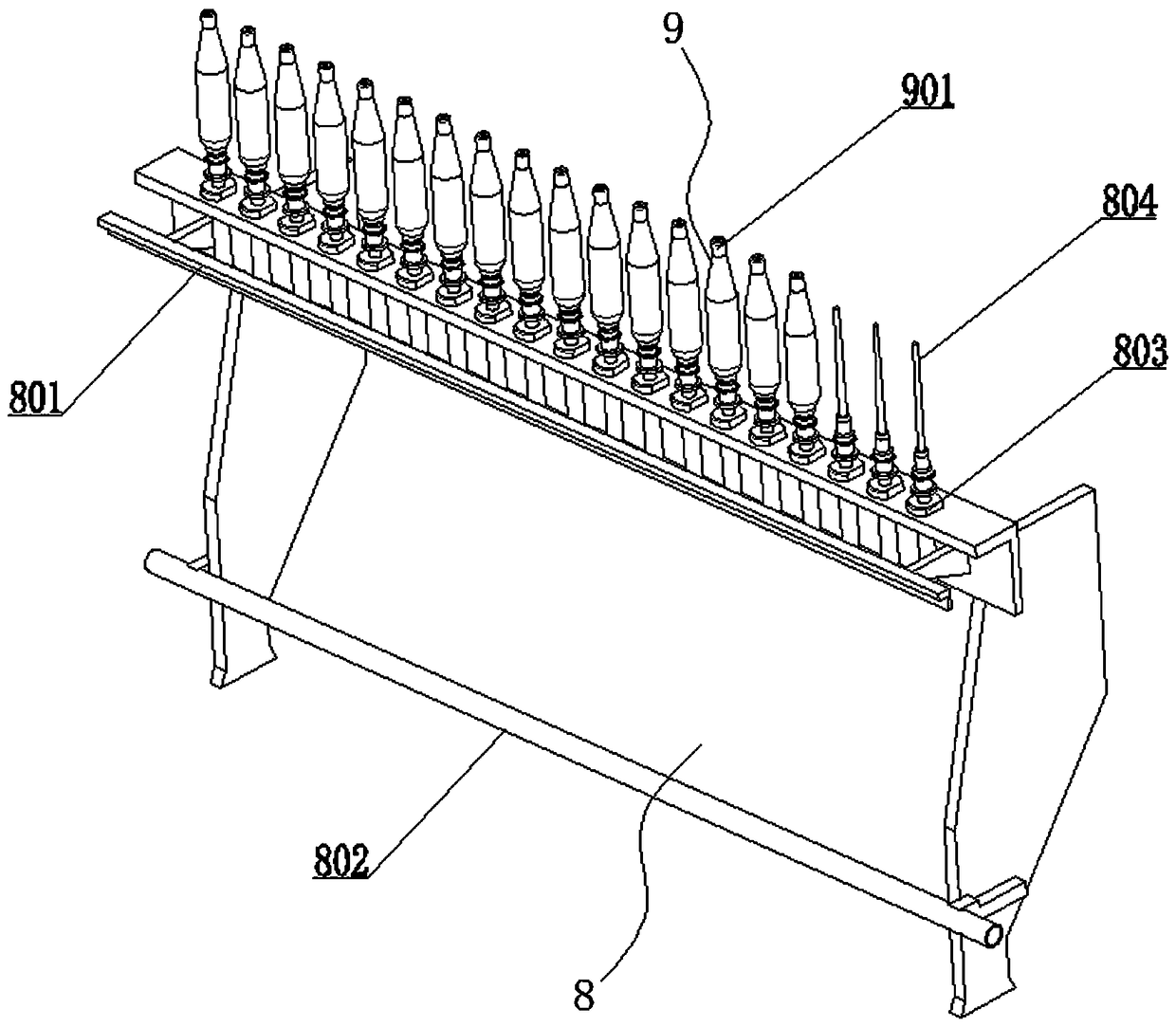

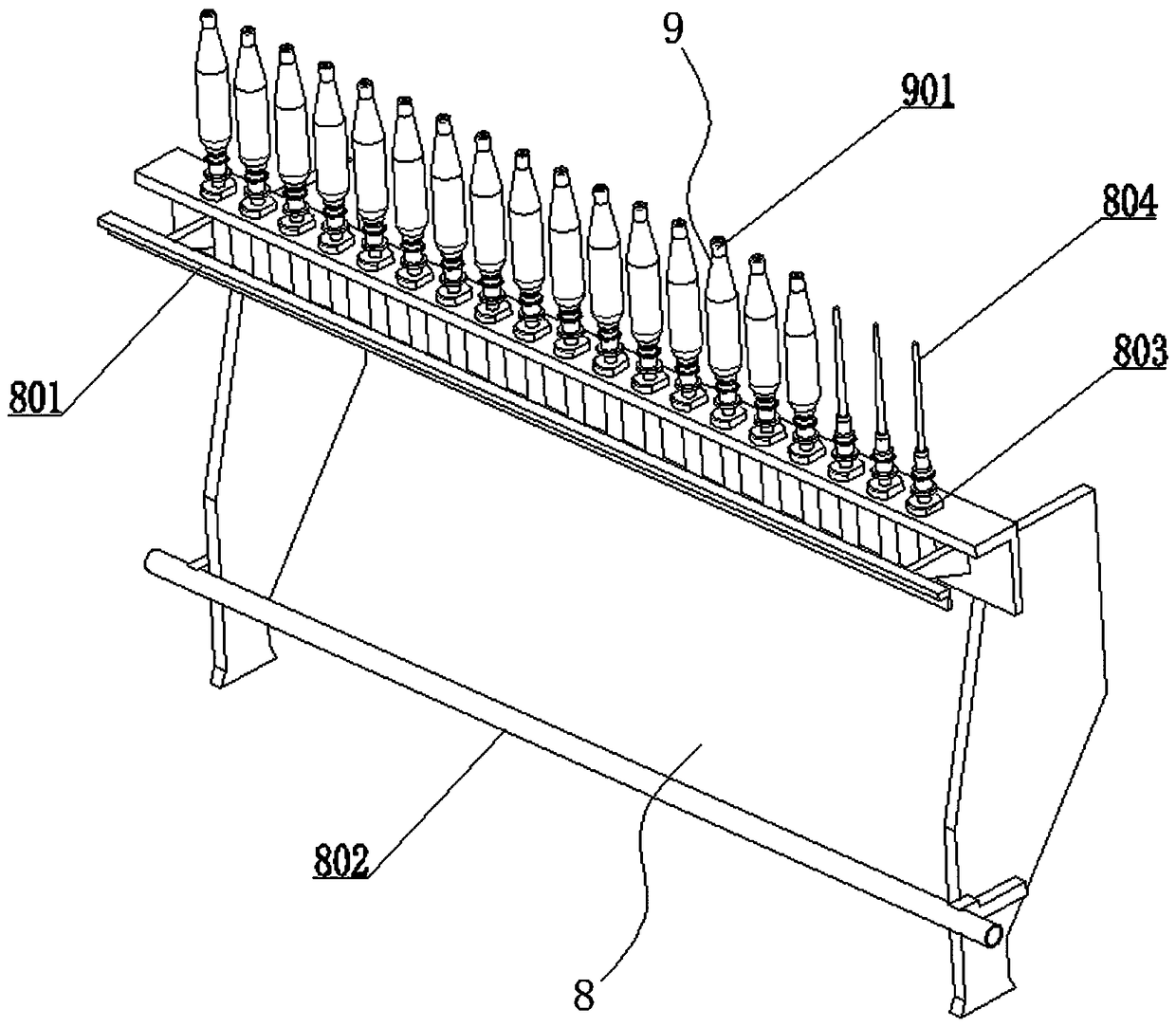

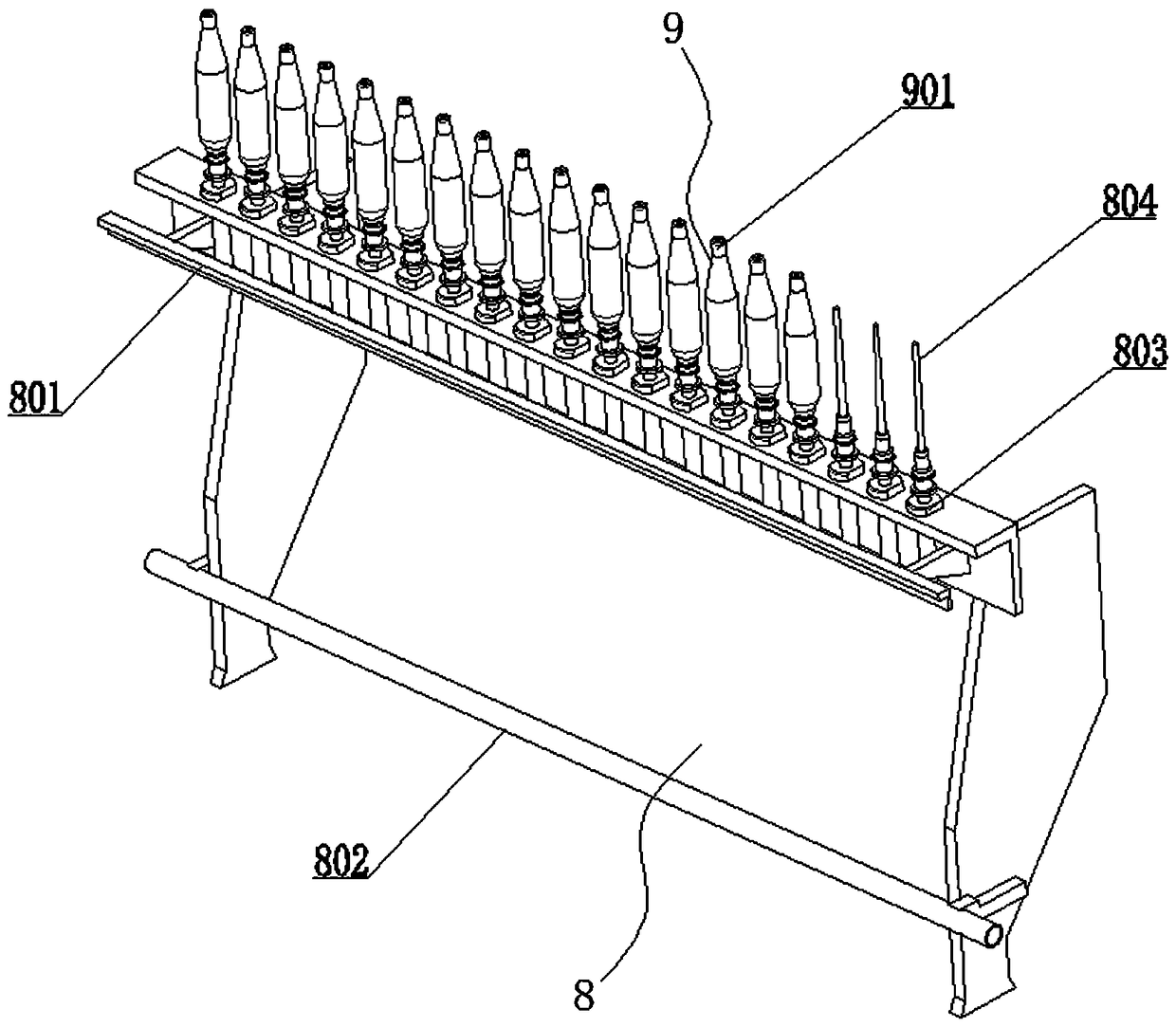

Tube pulling frame assembly for worsted doffing machine

The invention relates to a bobbin-pulling machine frame assembly of a finely-spun yarn removing machine. The bobbin-pulling machine frame assembly is arranged on the right side of a machine frame moving trolley; the bobbin-pulling machine frame assembly comprises a bobbin-pulling upper fixing plate, a bobbin-pulling sliding base upper track box, a bobbin-pulling lower fixing plate, a bobbin-pulling sliding base lower track box, an upper and lower bottom plate fixing upright post, an embedding force reaction force protection track, an embedding force spring compression track, a slide rod deviation-preventing inner track, a grabbing lug boss and a loosening lug boss; each working node is reliable in operating action, accurate in pace, small in size and light in weight; the structure of the conventional fine spinning machine is not required to be transformed. The bobbin-pulling machine frame assembly is small in power load, and a trolley is driven by a single motor or manually without using a motor to achieve fast bobbin pulling, so that yarn removal, causing no damage to a bobbin and a spindle, is achieved.

Owner:荣德明

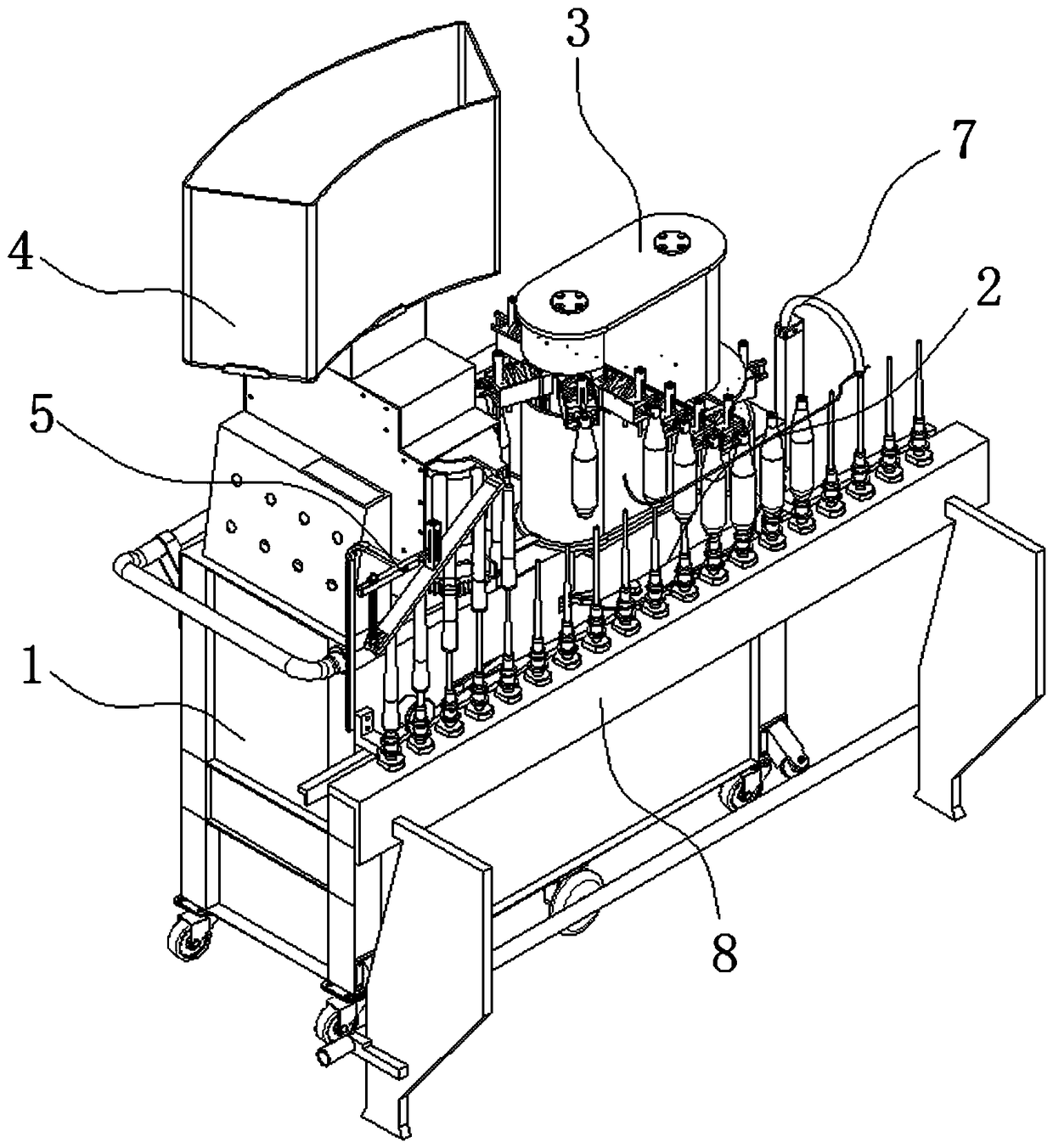

Pipe inserting executing device of fine-spinning doffing machine

The invention relates to a fine-spinning doffing machine. The fine-spinning doffing machine comprises a rack moving trolley, an electric appliance control cabinet, a pipe inserting and pulling positioning power device, a pipe pulling device, a pipe inserting device, a yarn pressing device, a cutting and chopping combined yarn shearing device and a pipe pressing device. After a vehicle box body and spindle rods of a fine spinning machine are subjected to inserting and pulling station correspondence, and vertical and parallel positioning through a spindle pitch positioning device, a walking supporting device and a walking parallel positioning device, a trolley walking driving device drives to run along upper and lower doffing frames of the fine spinning machine; the crawler-type positioning transmission belt is engaged with each spindle of the fine spinning machine; and the machine is used for feeding along a rail of the fine spinning machine; and meanwhile, integrated operation of pipe pulling, pipe inserting, yarn pressing, yarn shearing and pipe pressing is realized through accurately controlling the yarn pressing device, the pipe pulling device, the cutting and chopping combined yarn shearing device, the pipe inserting device and the pipe pressing device, which correspond to each spindle rod.

Owner:荣德明

yarn guide for textile machinery

The invention relates to the technical field of textile machinery, in particular to a yarn guide for textile machinery, which includes a mounting base, a wire inlet frame and a wire outlet frame are symmetrically arranged on the upper side of the installation base, and two The first guide wheel has a wet assembly on the incoming wire frame, a dry assembly on the outgoing wire frame, and an adjustable elastic limit assembly on the installation base for elastically limiting the rotating arm. Both ends of the rotating arm are symmetrically arranged. Two second guide wheels, the installation base is provided with a twisting assembly corresponding to the position of the incoming wire frame. The invention is used for yarn guiding operation during weaving, which can ensure that the yarn is in a tight state, and at the same time avoid tearing or yarn falling off caused by the sudden stop of the machine, and it is also lubricated by alcohol during yarn guiding to avoid excessive friction The yarn is broken, and the yarn is tightened while lubricating, and the alcohol on the yarn is dried when it is exported, and it has a cleaning effect at the same time.

Owner:嘉兴市佳瑞思喷织有限公司

Yarn pressing device for worsted doffer

The invention relates to a yarn pressing device of a spinning doffer. The yarn pressing device comprises a yarn pressing fixing bracket, a yarn pressing linear motor, a guide steel wire, a guide tube and a yarn pressing steel wire, wherein the yarn pressing fixing bracket is connected with the right side of a machine frame movement trolley or the right side of a tube drawing device; the yarn pressing linear motor is arranged in the yarn pressing fixing bracket, and is connected with the lower end of the guide steel wire; the guide steel wire is penetrated into the guide steel wire; the guide tube is fixedly penetrated into the upper end of the yarn pressing fixing bracket; the upper end of the guide steel wire is connected with the yarn pressing steel wire, and the yarn pressing steel wire is parallel with the arrangement direction of an ingot rod of a spinning machine, and is arranged at the front side of the ingot rod; the tail end of the yarn pressing steel wire is bent upwards, and extends to the left side of a rail box under a tube drawing slide seat.

Owner:荣德明

A mechanical arm device for worsted spinning doffing machine

The invention relates to a manipulator device of a fine-spinning doffing machine. The manipulator device comprises a manipulator sliding block connection seat, a manipulator lower locating plate, a clamping force-bearing rod, a clamping linkage rod, a deflector rod retainer, a loosening force-bearing rod, a loosening linkage rod, a loosening push rod, a movable force arm, a clamping deflector rod, a loosening deflector rod, a supporting rod, a tension spring, a fixed force arm, a pressure spring, a first movable clamping claw and a second movable clamping claw. By the adoption of a pure mechanical mode, all working nodes are reliable in operation action, accurate in beat, small in size and light in weight, and the structure of the existing fine spinning machine is not needed to be transformed. Due to low power load, bobbins can be quickly pulled out with a single motor or by pushing a trolley manually without a motor, so that scatheless doffing of the bobbins and spindles is realized.

Owner:荣德明

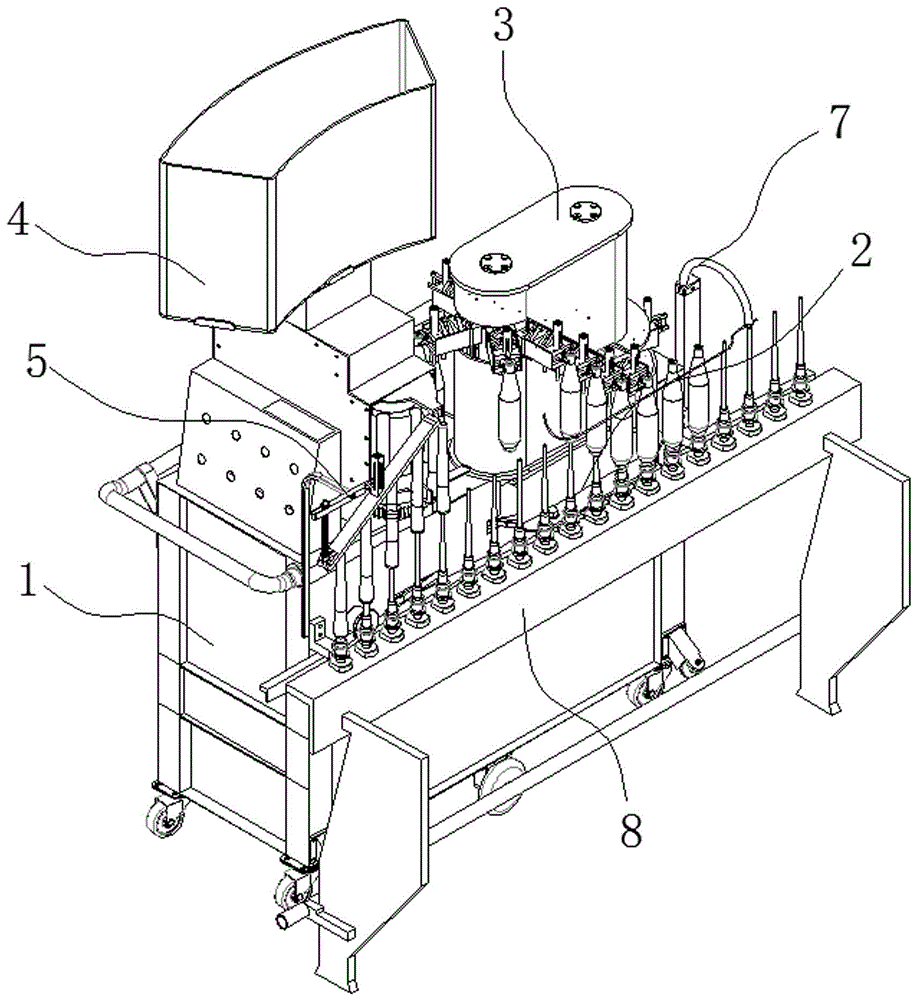

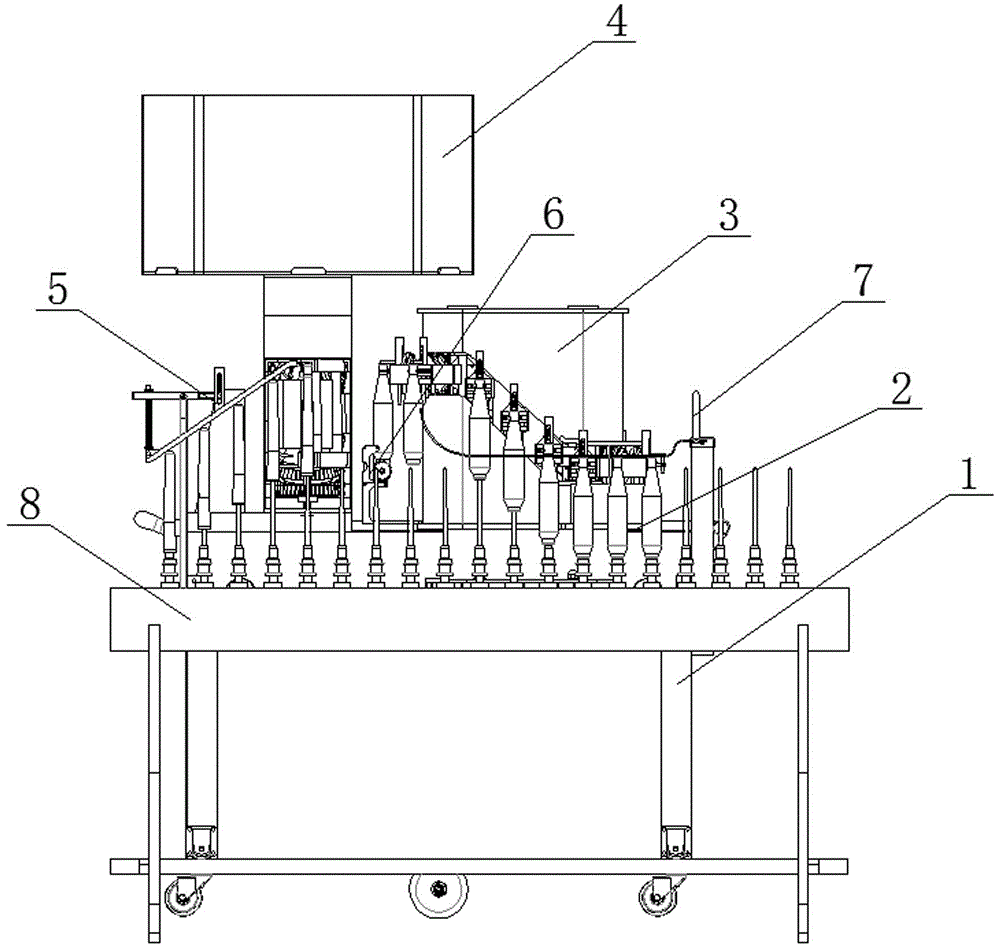

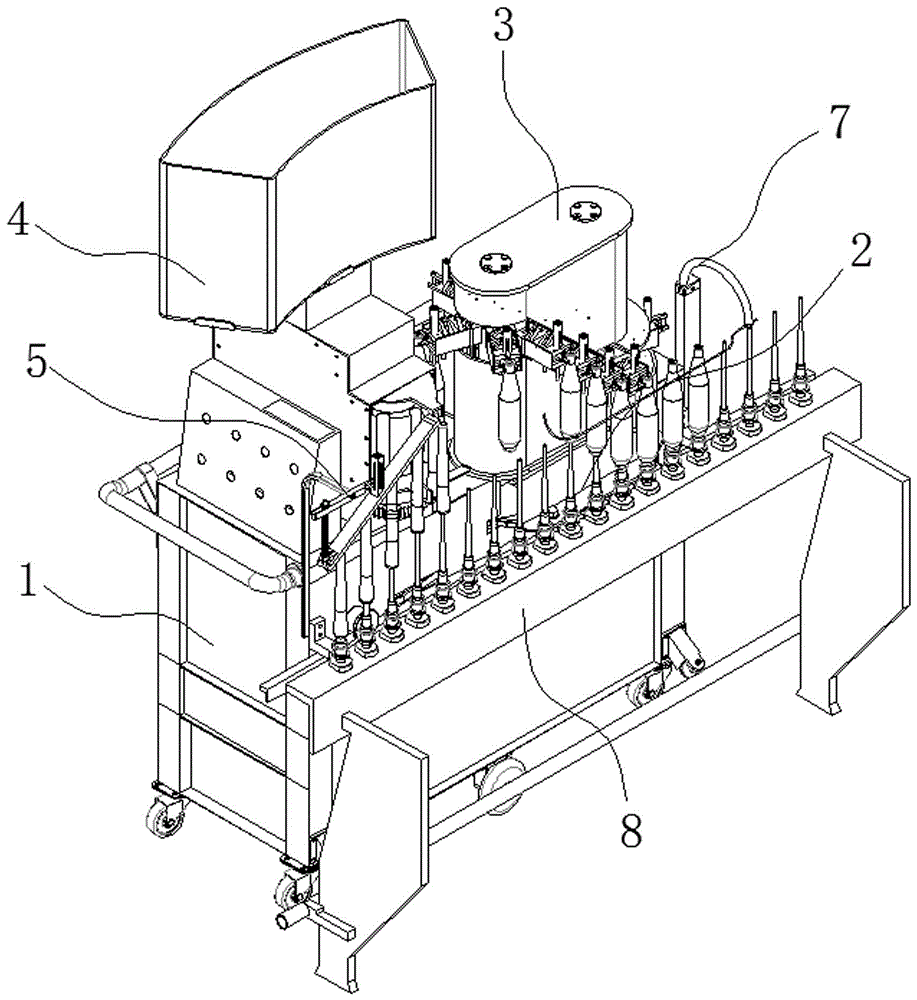

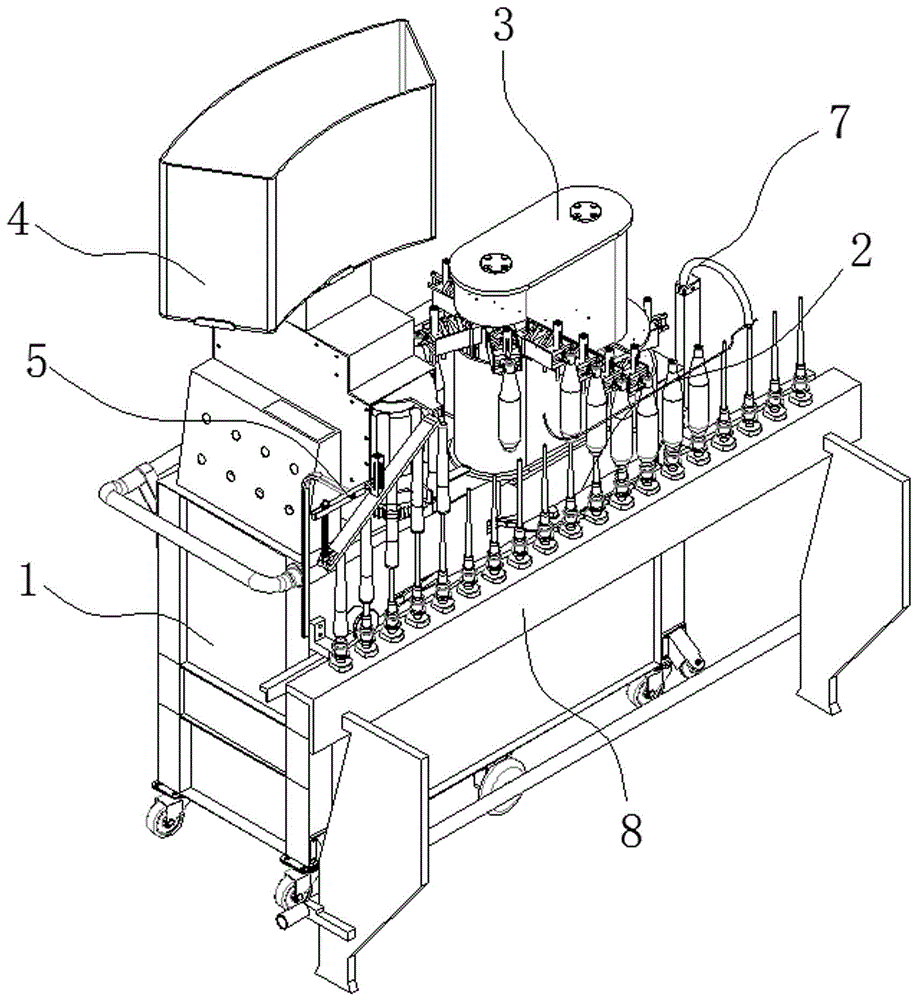

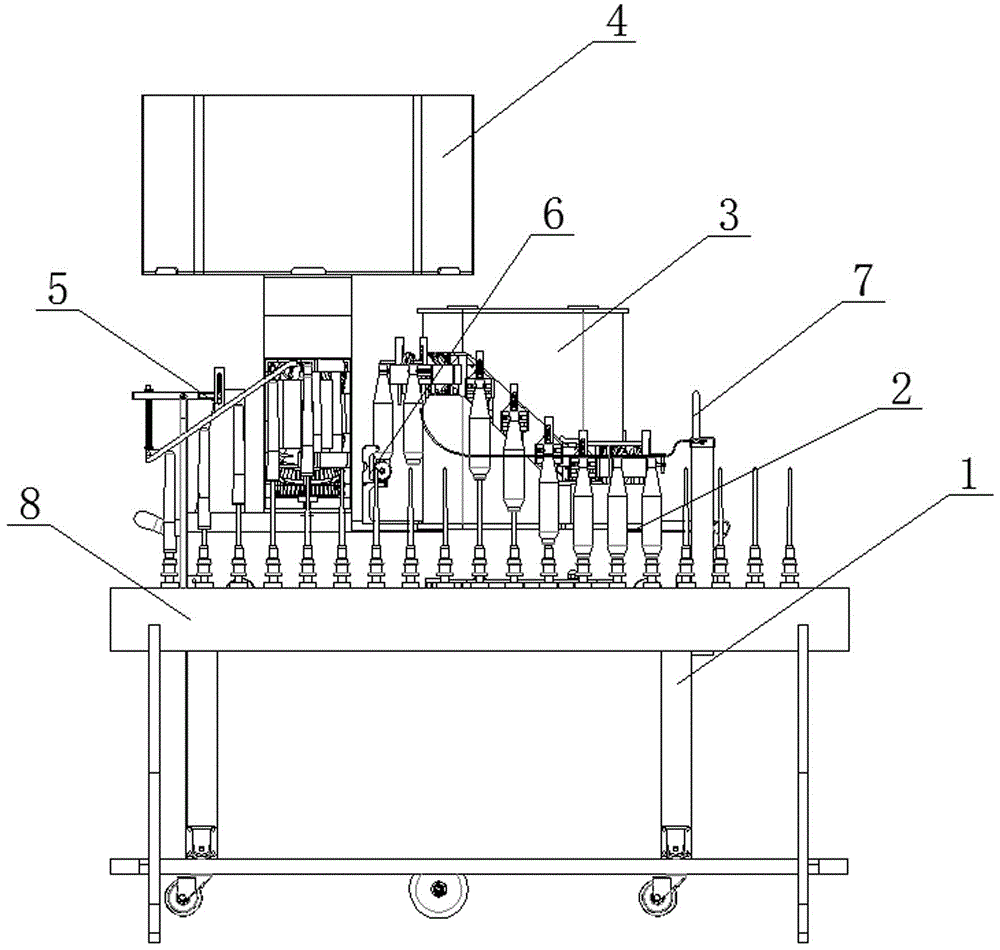

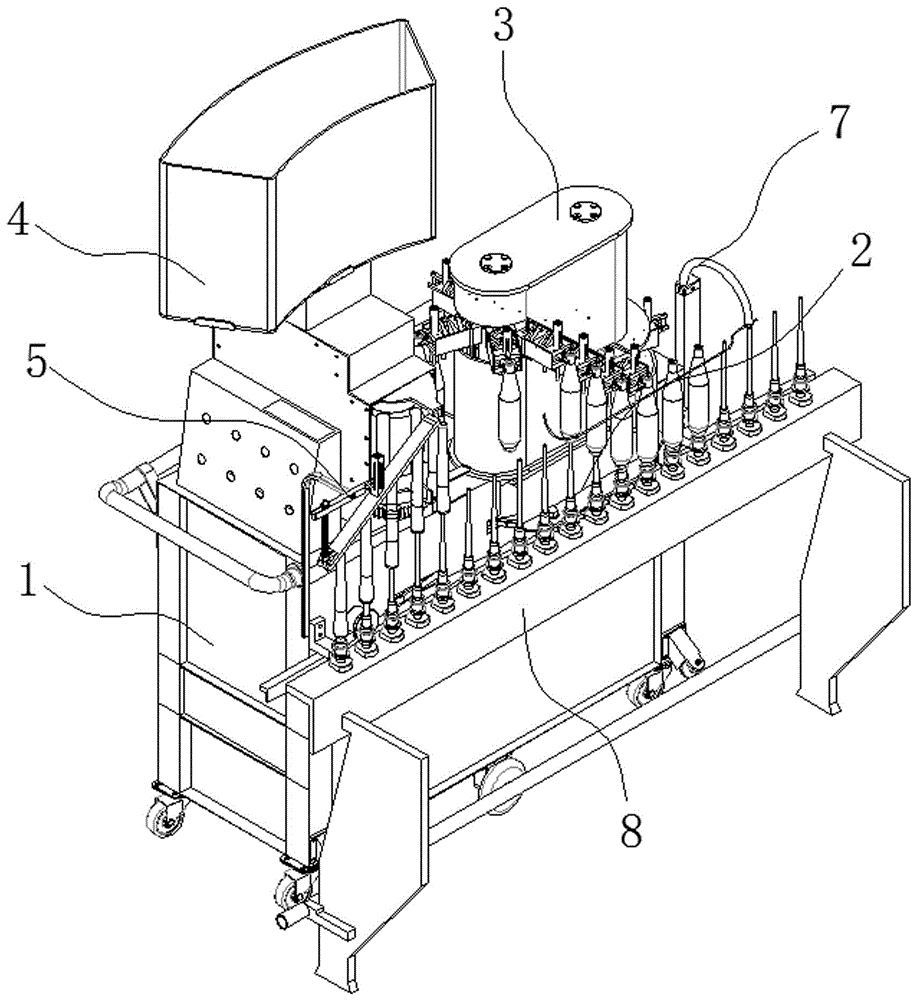

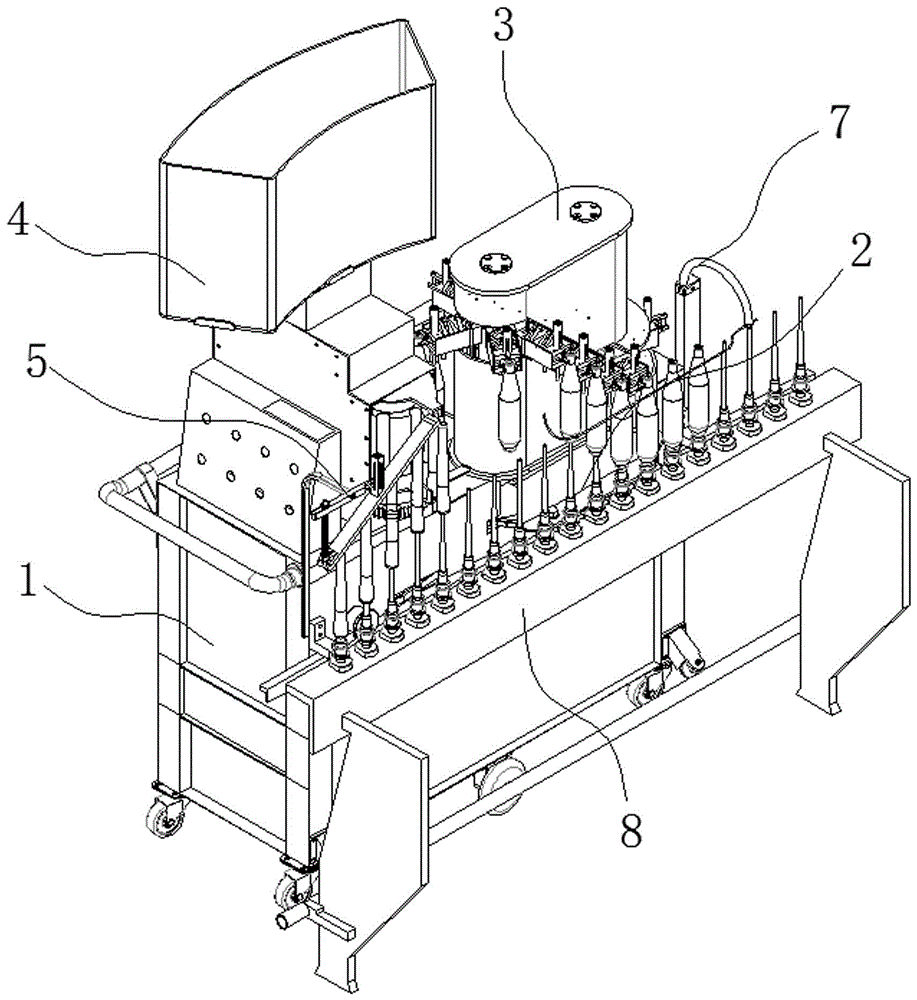

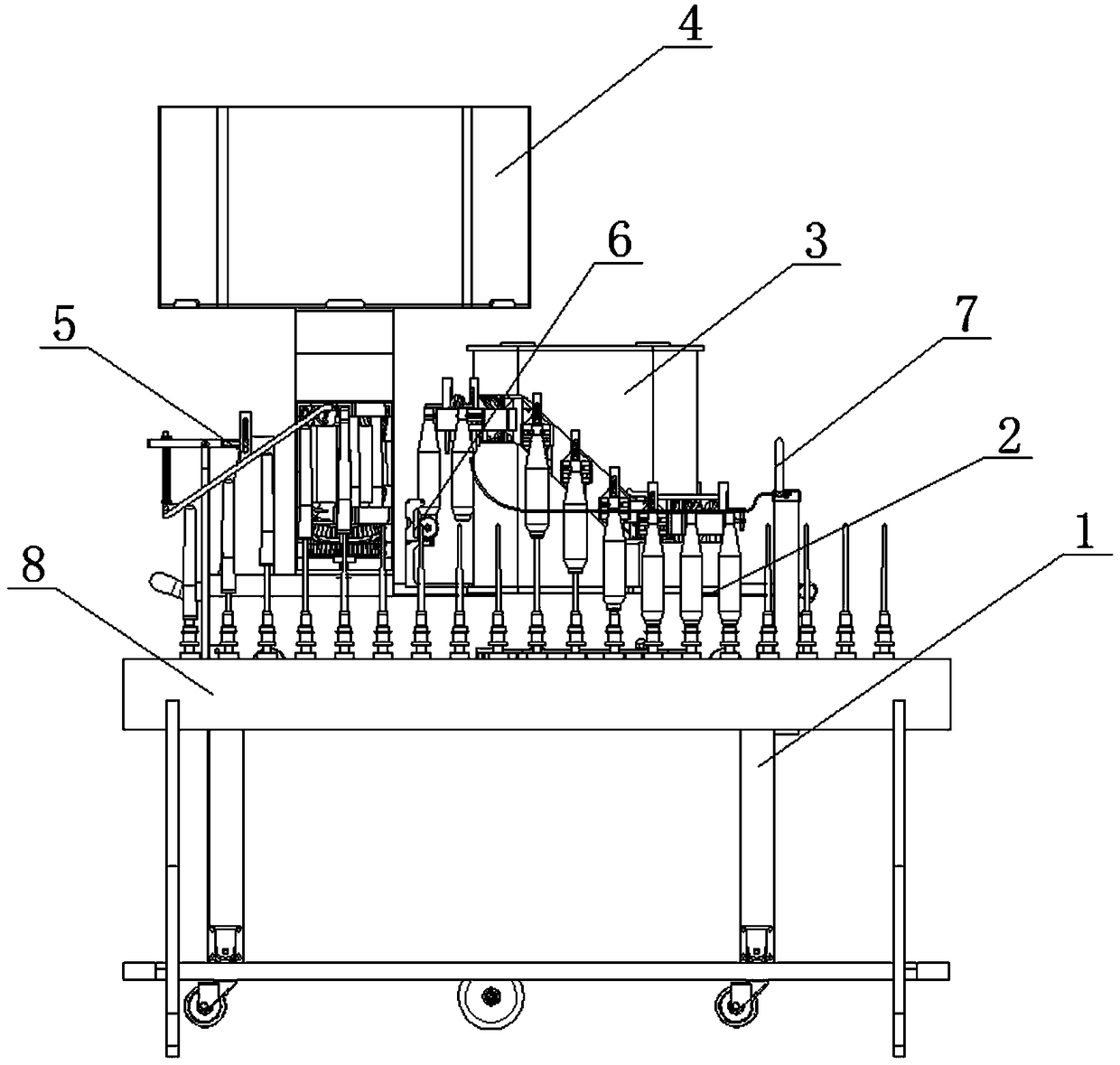

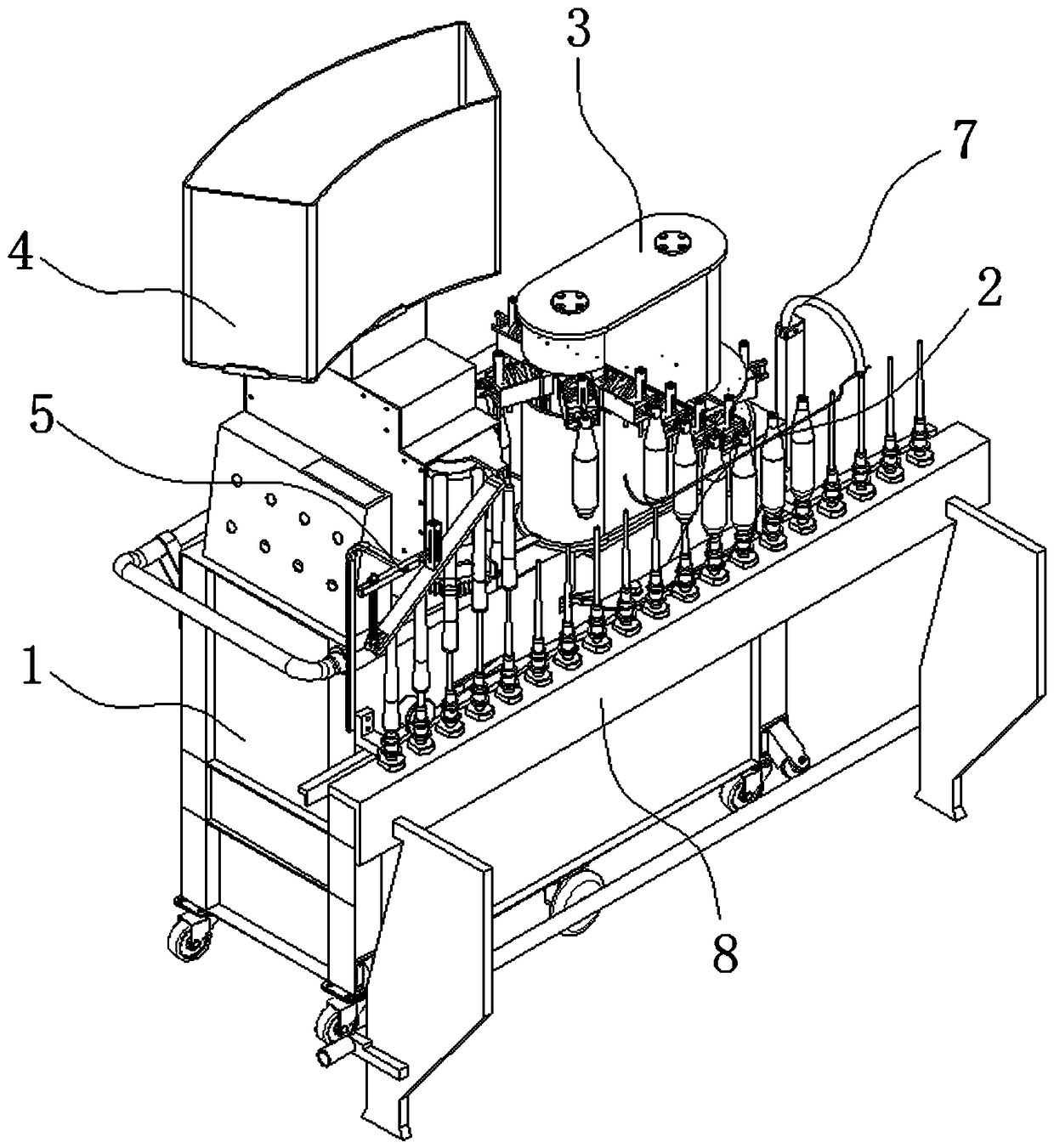

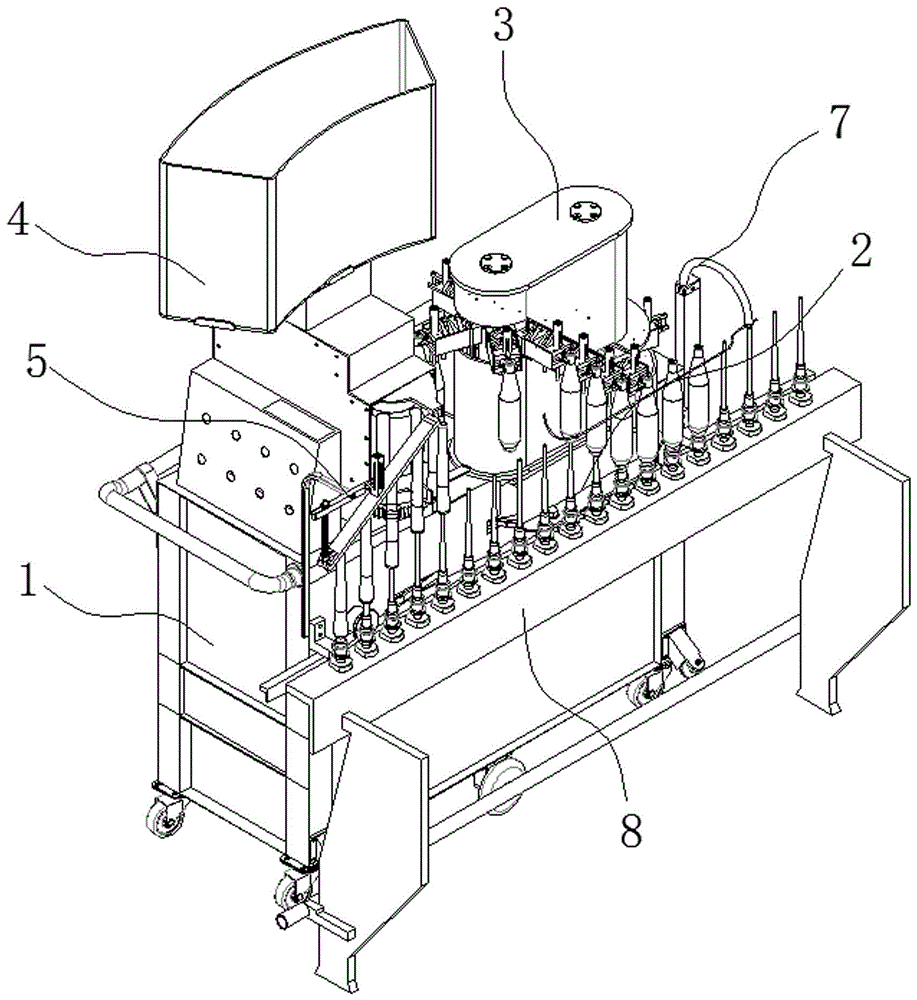

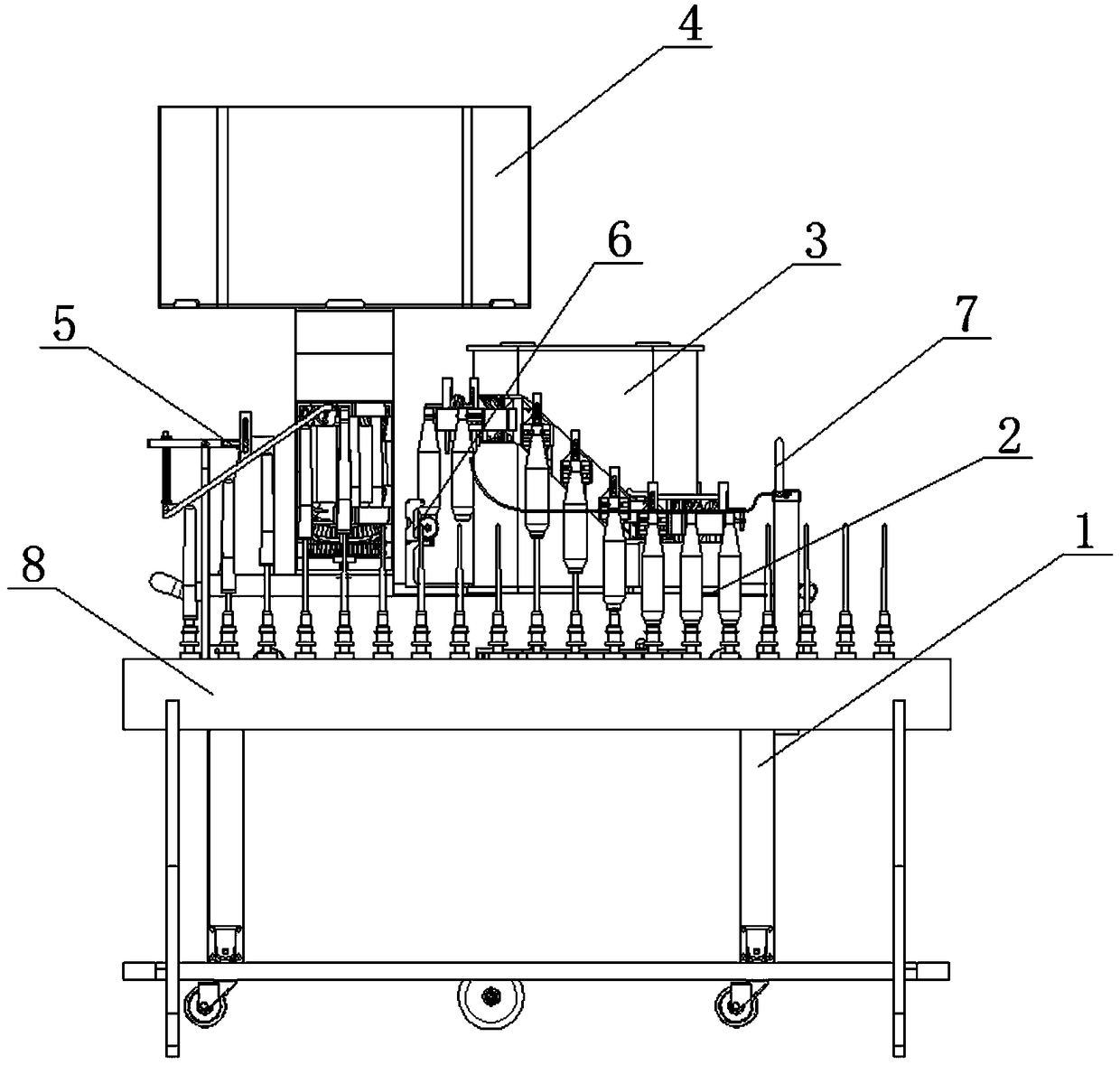

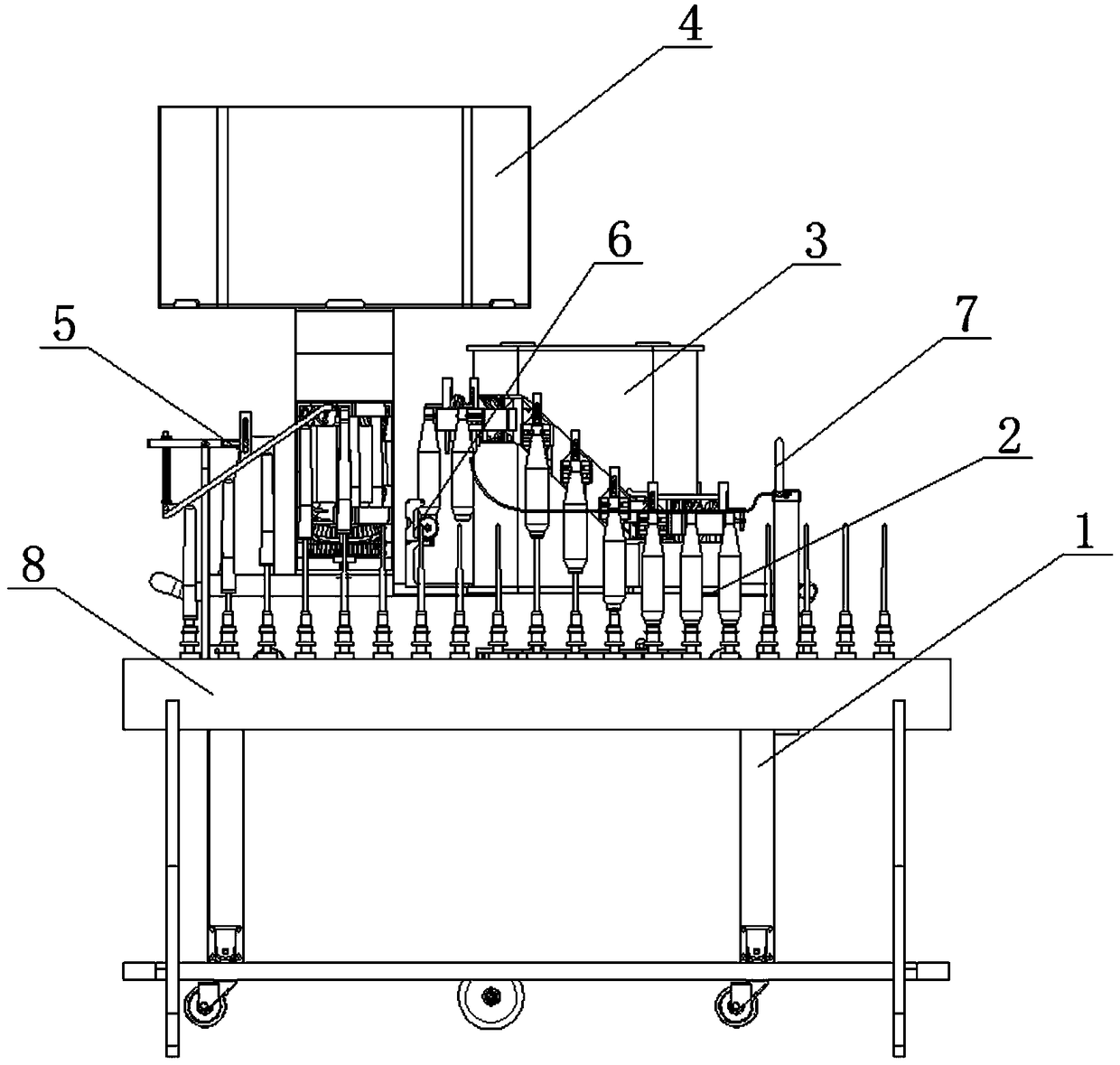

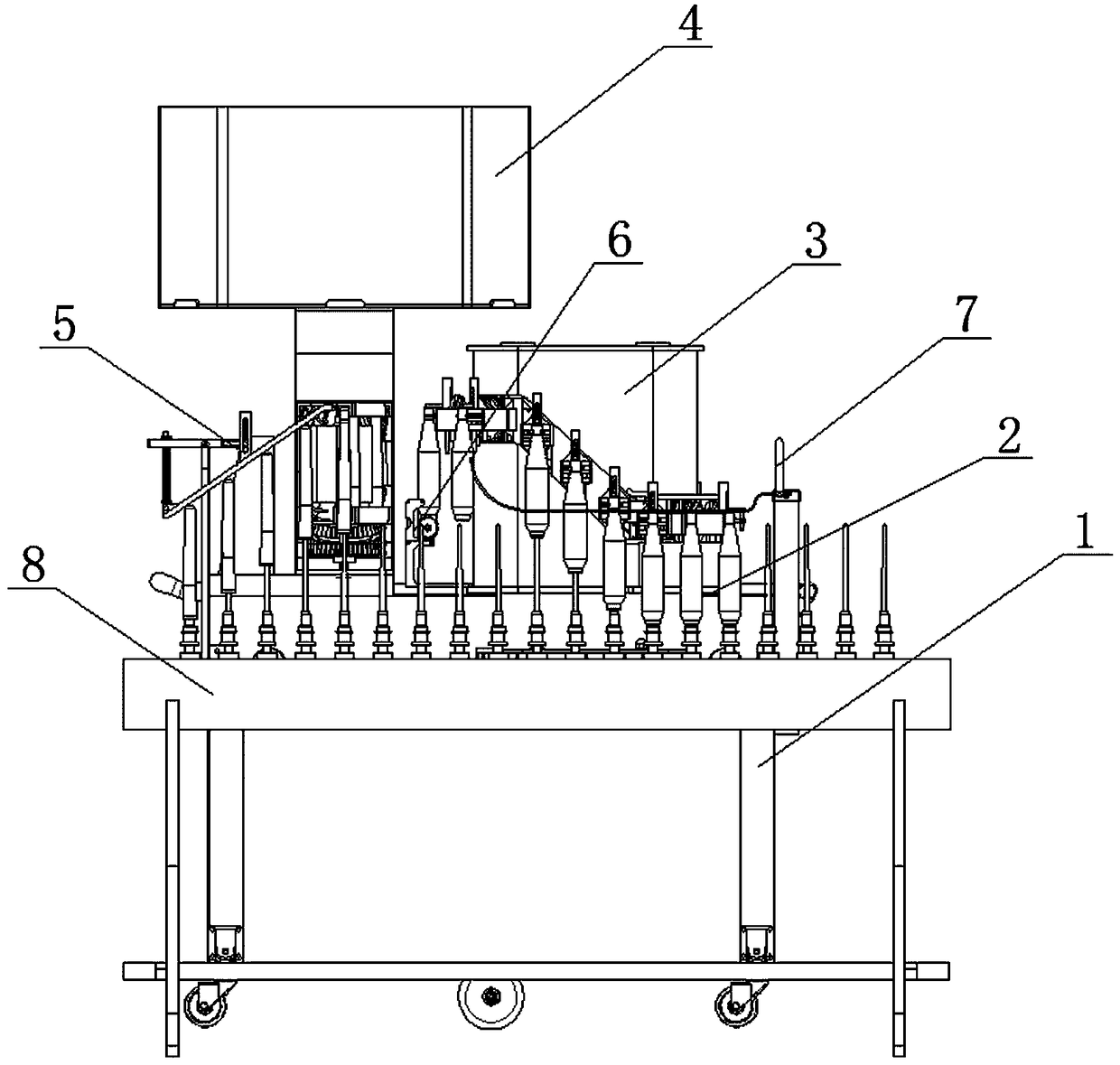

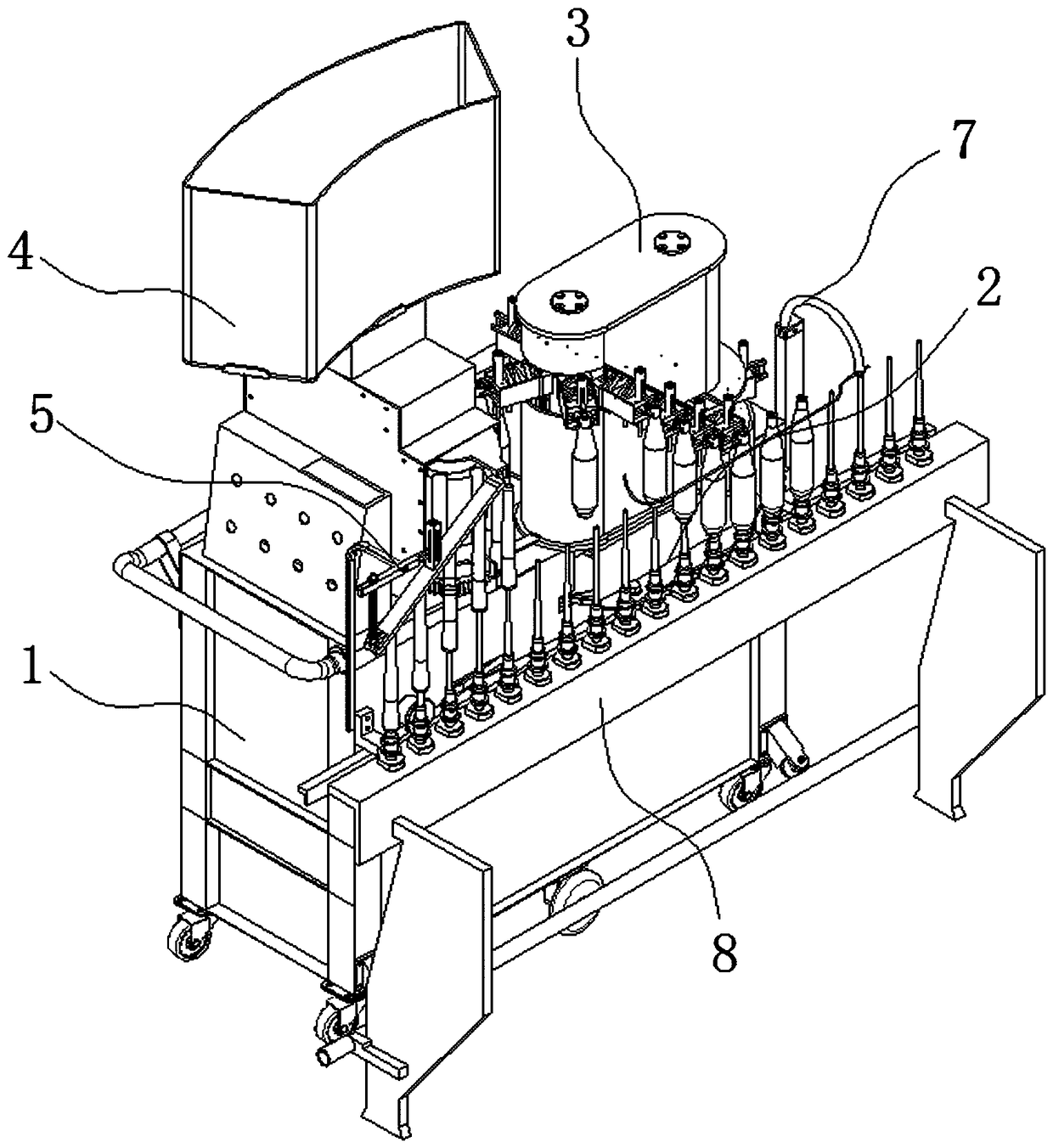

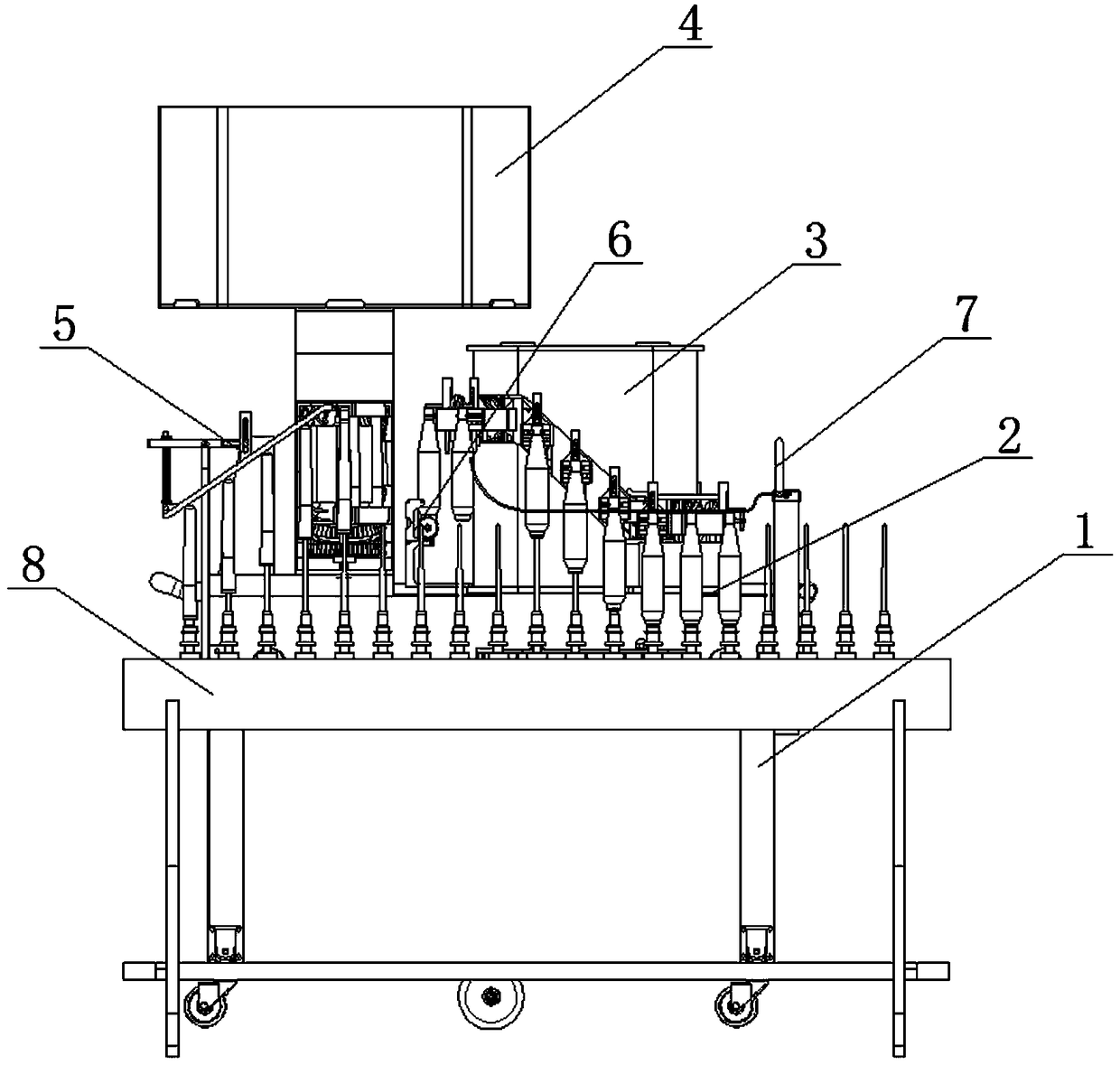

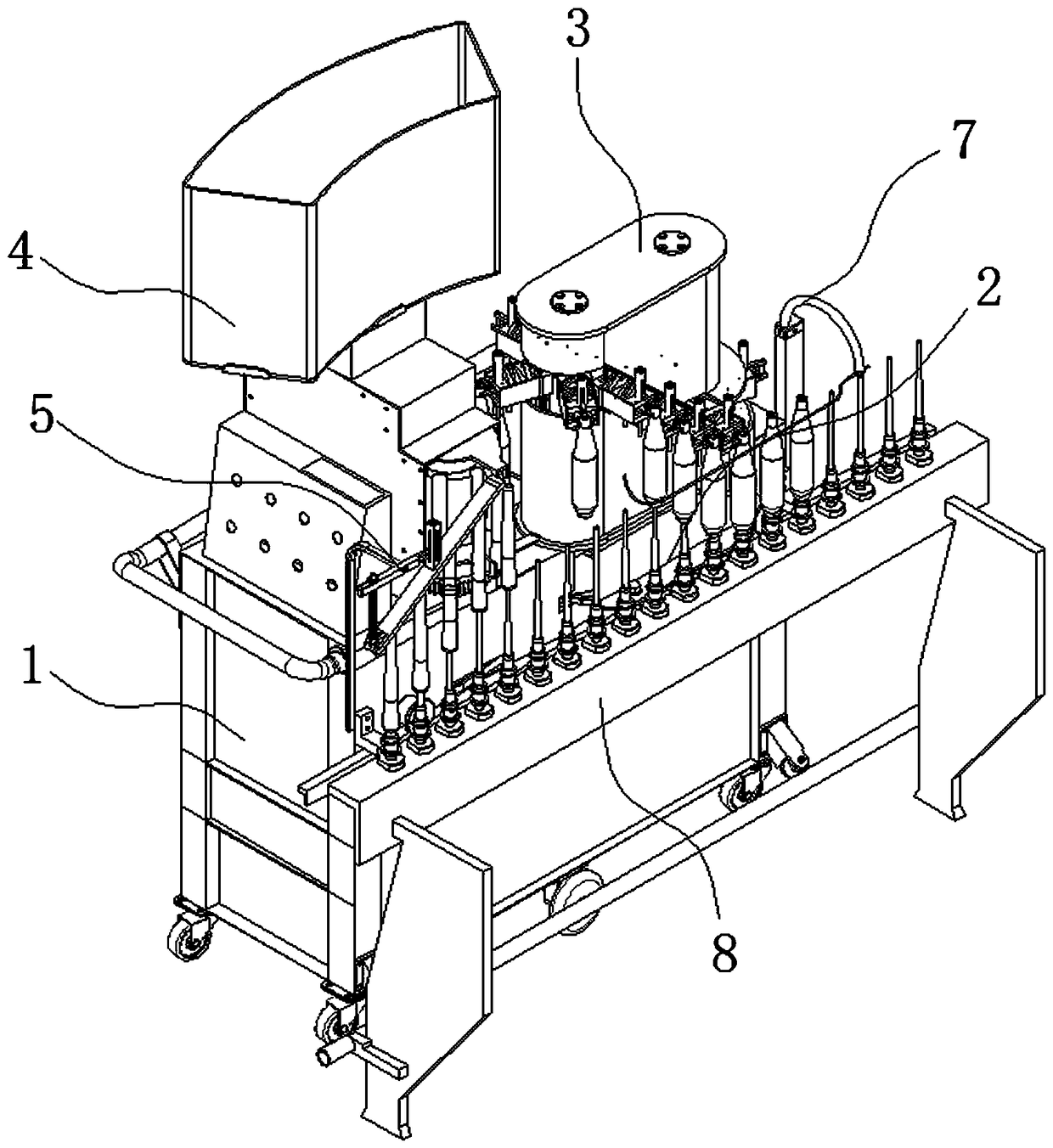

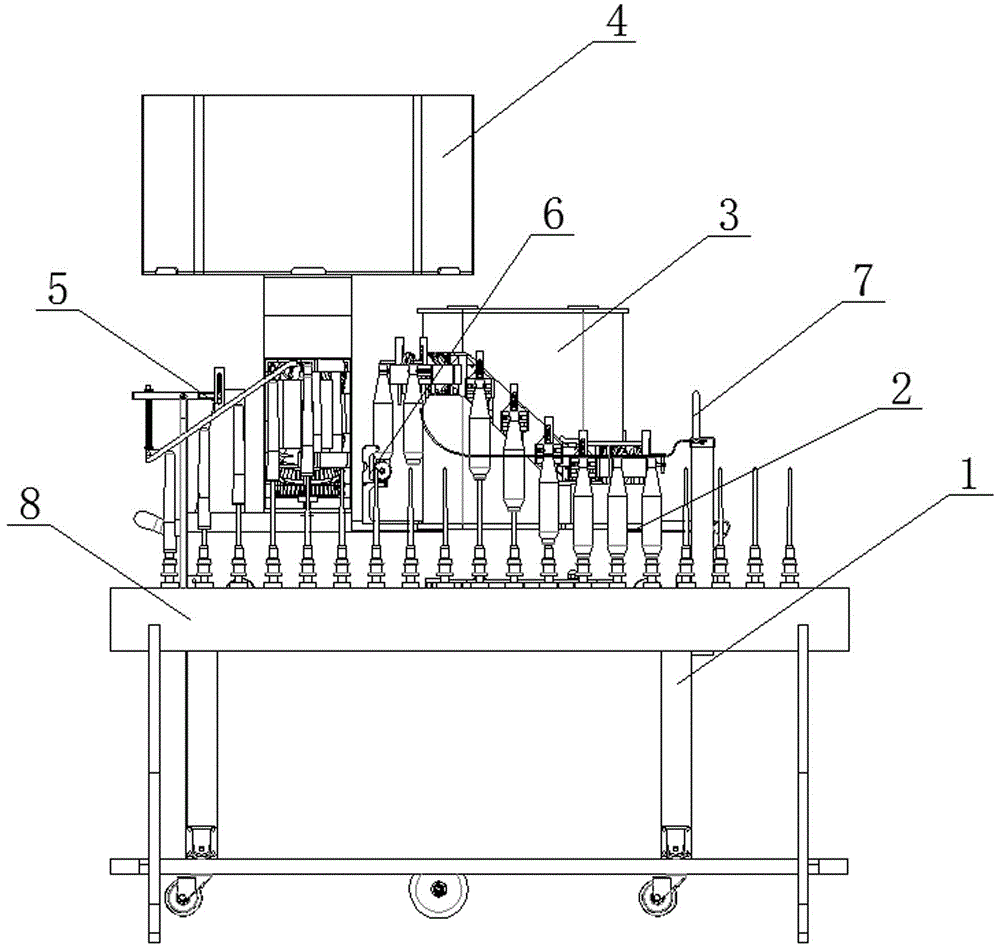

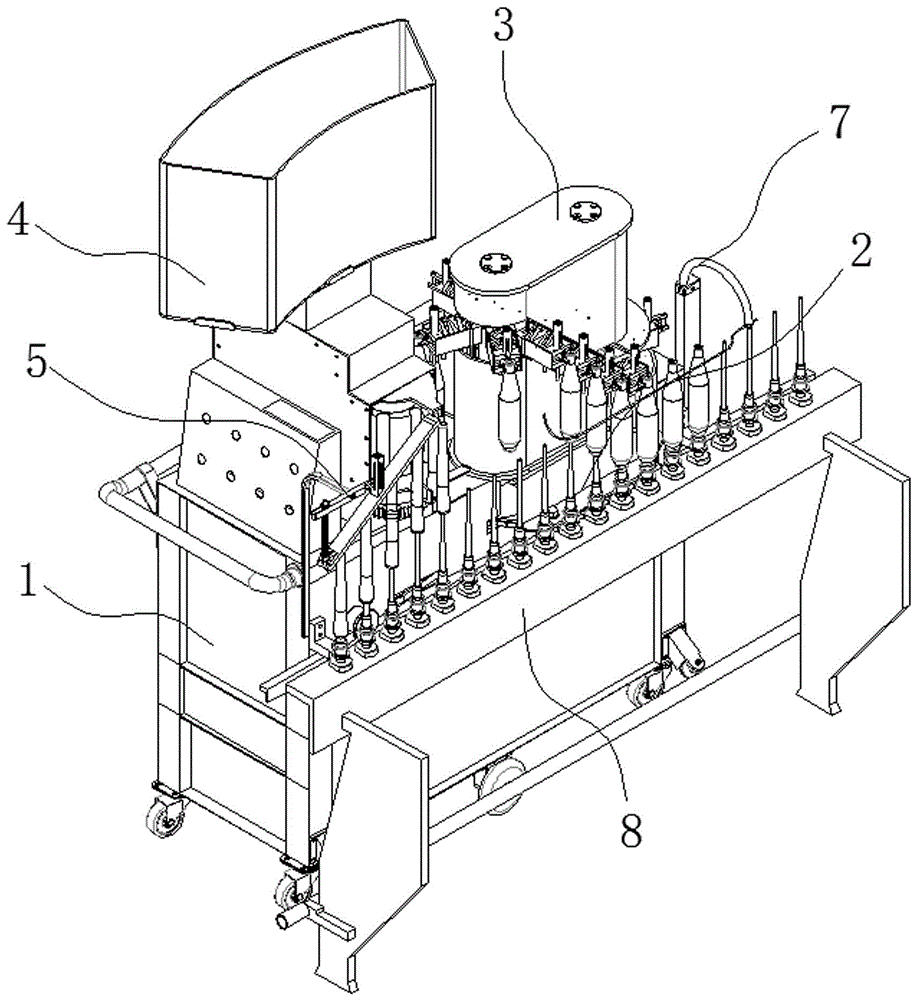

A spinning doffing machine

The invention relates to a worsted doffing machine. The worsted doffing machine comprises a rack moving trolley, an electrical equipment control box, an inserting and drawing tube positioning power device, a tube drawing device, a pipe inserting device, a yarn pressing device, a chopping composite yarn cutting device and a pipe pressing device. After corresponding, vertical and parallel positioning with a fine spinning machine spindle blade inserting and drawing station is completed on a trolley box through a spindle pitch positioning device, a walking support device and a walking parallel positioning device, a trolley walking driving device is driven to travel along an upper creel and a lower creel of a fine spinning machine, by combining the condition that a crawler-type positioning driving belt is meshed with each ingot phase of the fine spinning machine, feeding is conducted along a fine spinning machine track, and meanwhile integrated operation of tube drawing, tube inserting, yarn pressing, yarn cutting and tube pressing corresponding to the yarn pressing device, the tube drawing device, the chopping composite yarn cutting device, the tube inserting device and the tube pressing device corresponding to each spindle blade is accurately controlled.

Owner:荣德明

A gripping and fitting force elimination assembly of a worsted doffing machine manipulator

The invention relates to a fine spinning doffer manipulator grabbing and embedding force eliminating assembly. Multiple manipulator grabbing and embedding force eliminating assemblies are uniformly spaced on a grabbing track; the manipulator grabbing and embedding force eliminating assembly comprises a linear slide rail, a linear slider, a chain fixing seat, a slide rail positioning roller, a guide vertical positioning frame, a guide vertical positioning roller and a manipulator grabbing and embedding force eliminating compound device; a pure mechanical mode is adopted in the whole tube drawing process, and each work node has the advantages of reliable operation action, accurate beat, small volume and light weight; and the existing spinning machine structure does not need to be transformed. With a low power load, a trolley can be pushed through a single motor or by labor without a motor to quickly draw a tube, and no-damage doffing is realized for a bobbin and a spindle.

Owner:荣德明

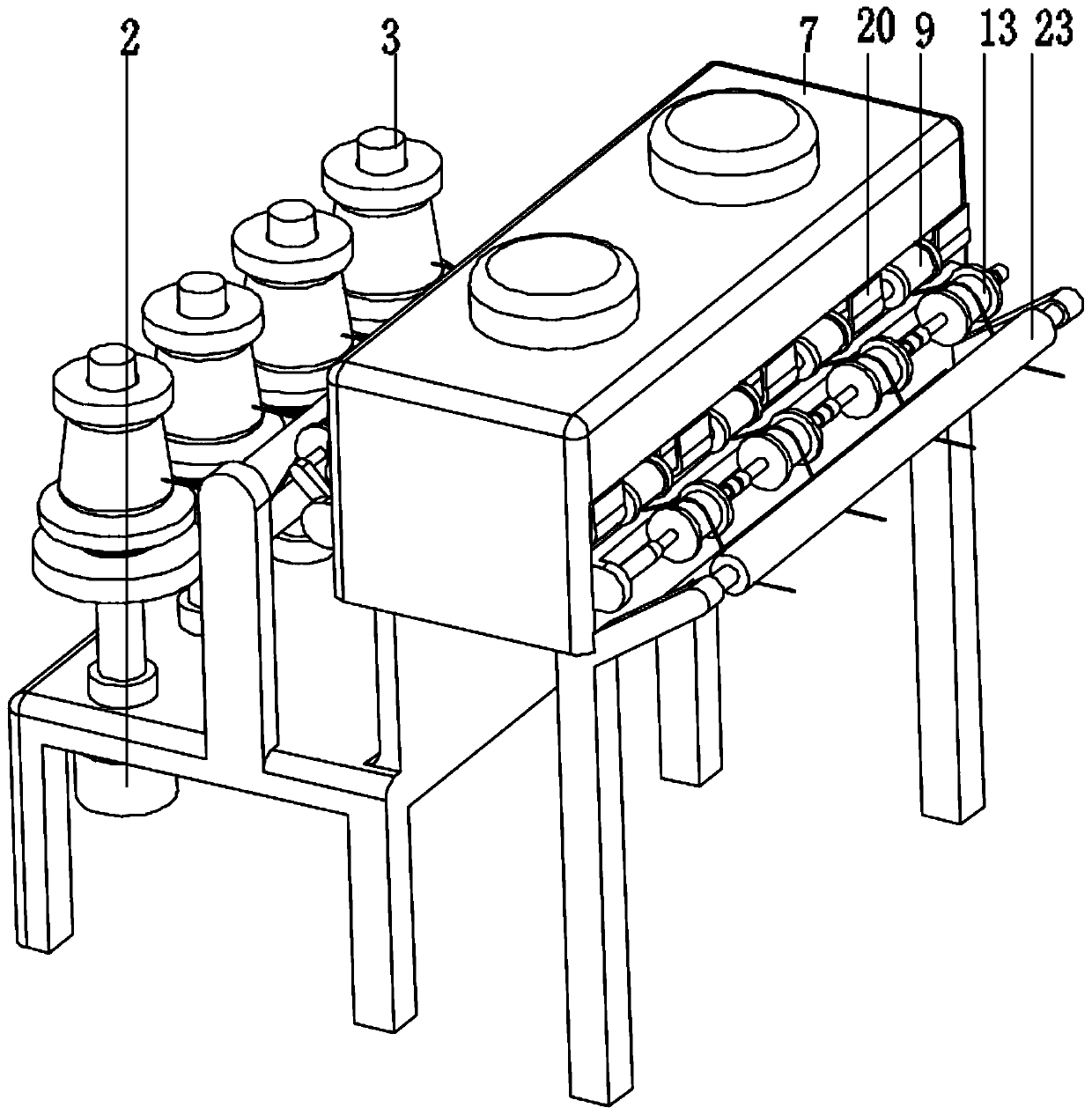

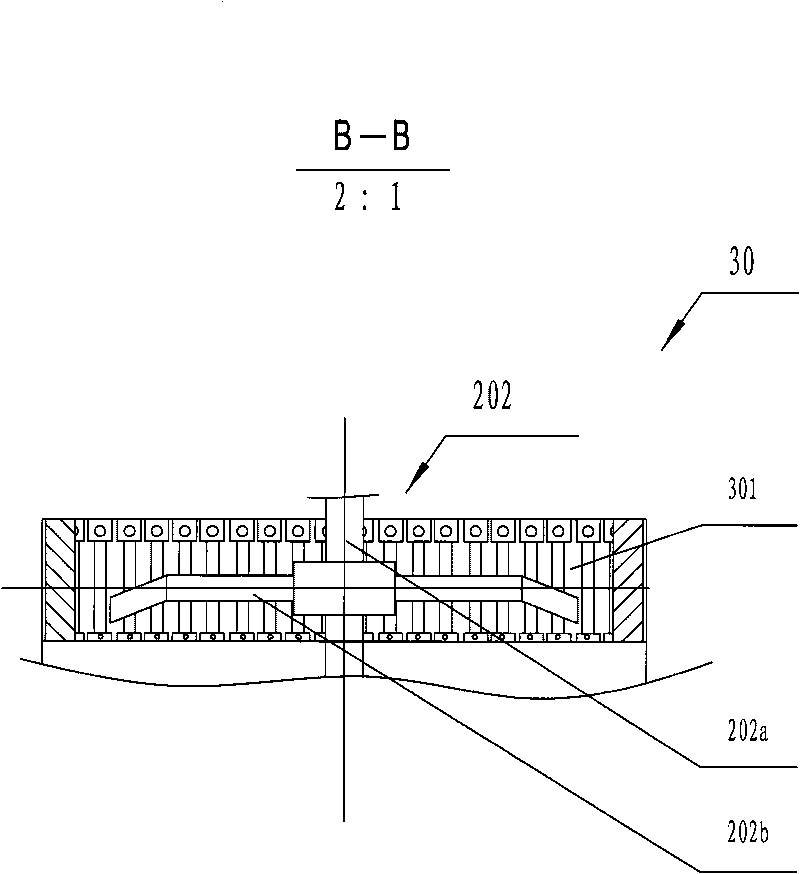

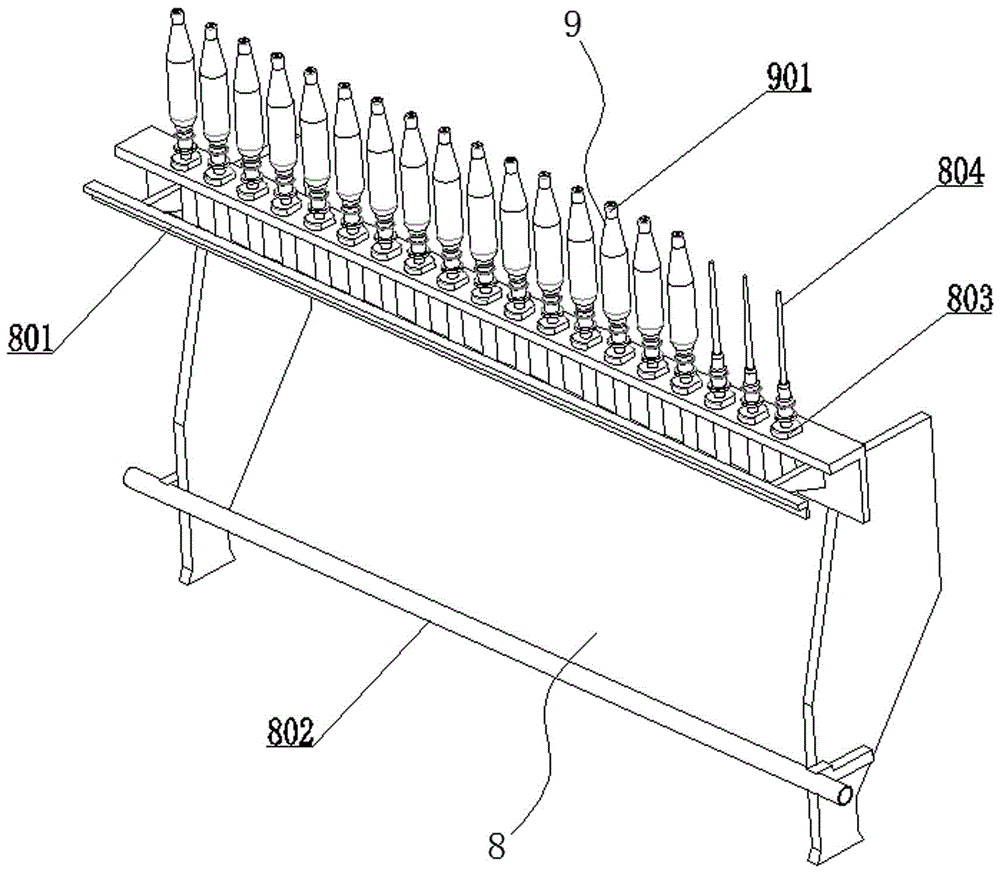

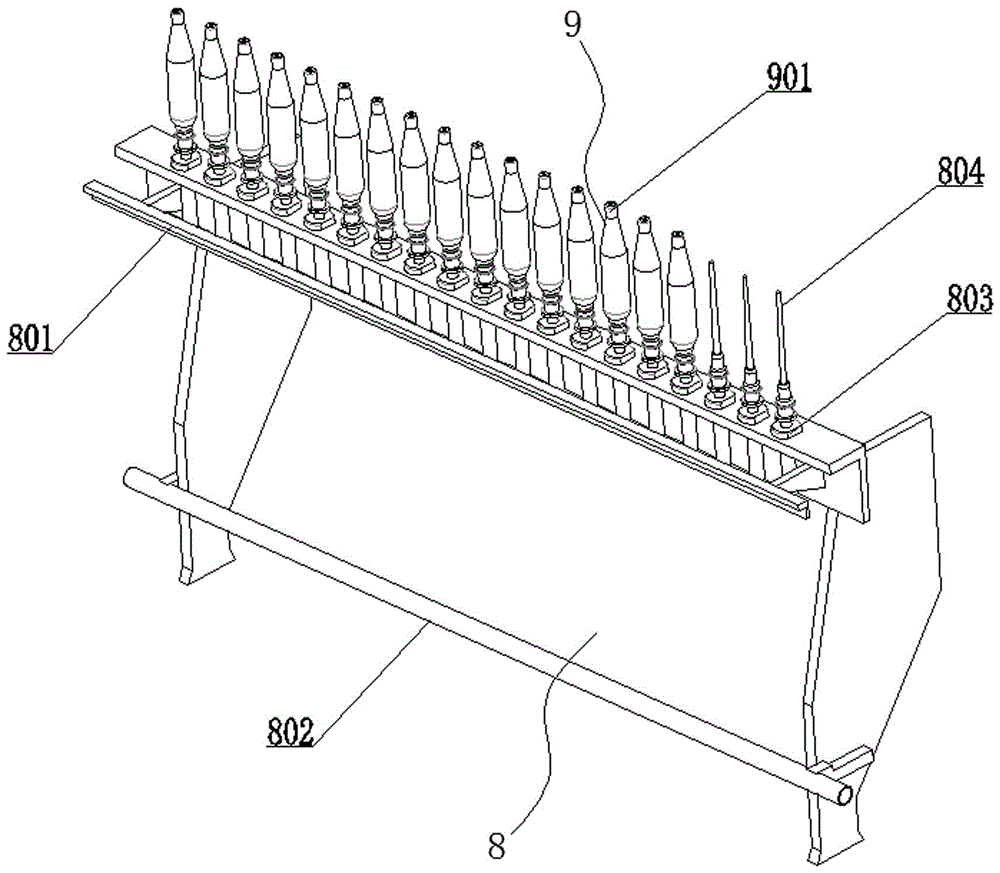

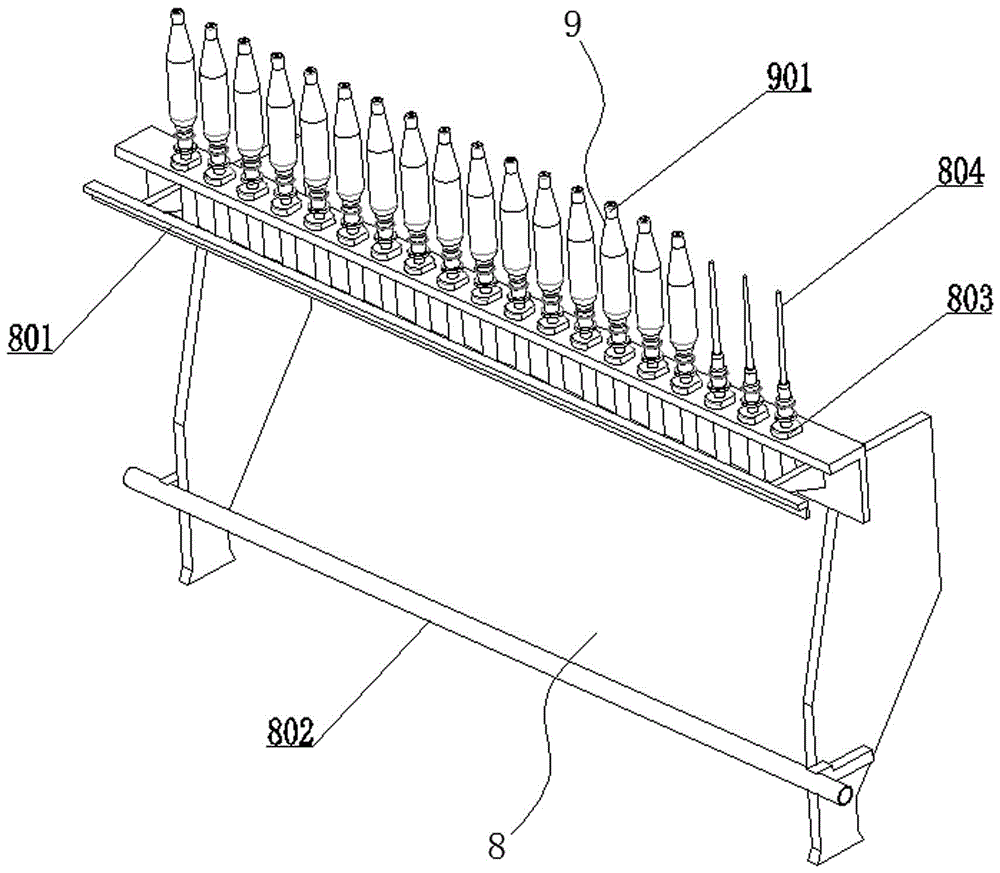

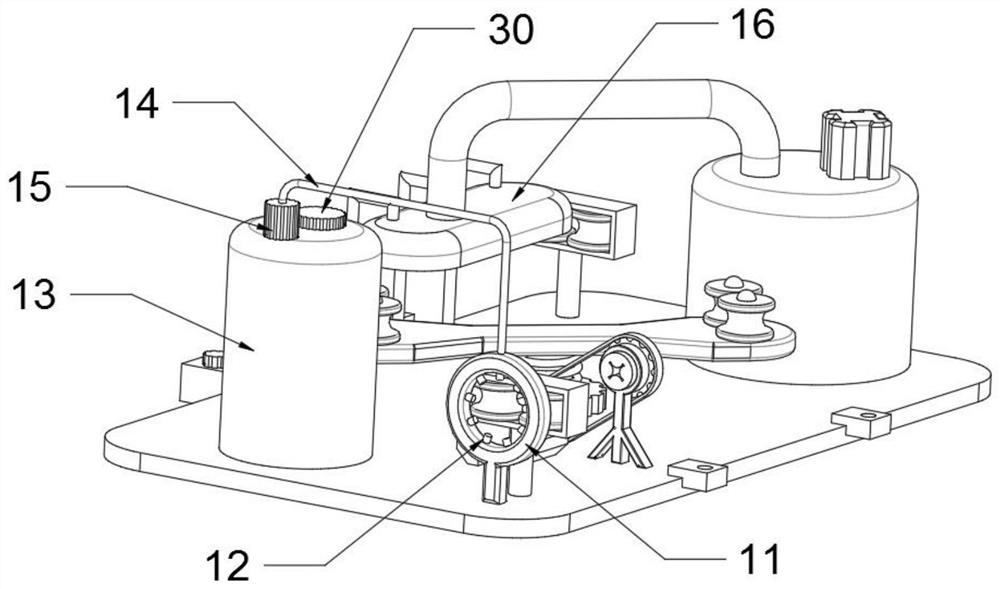

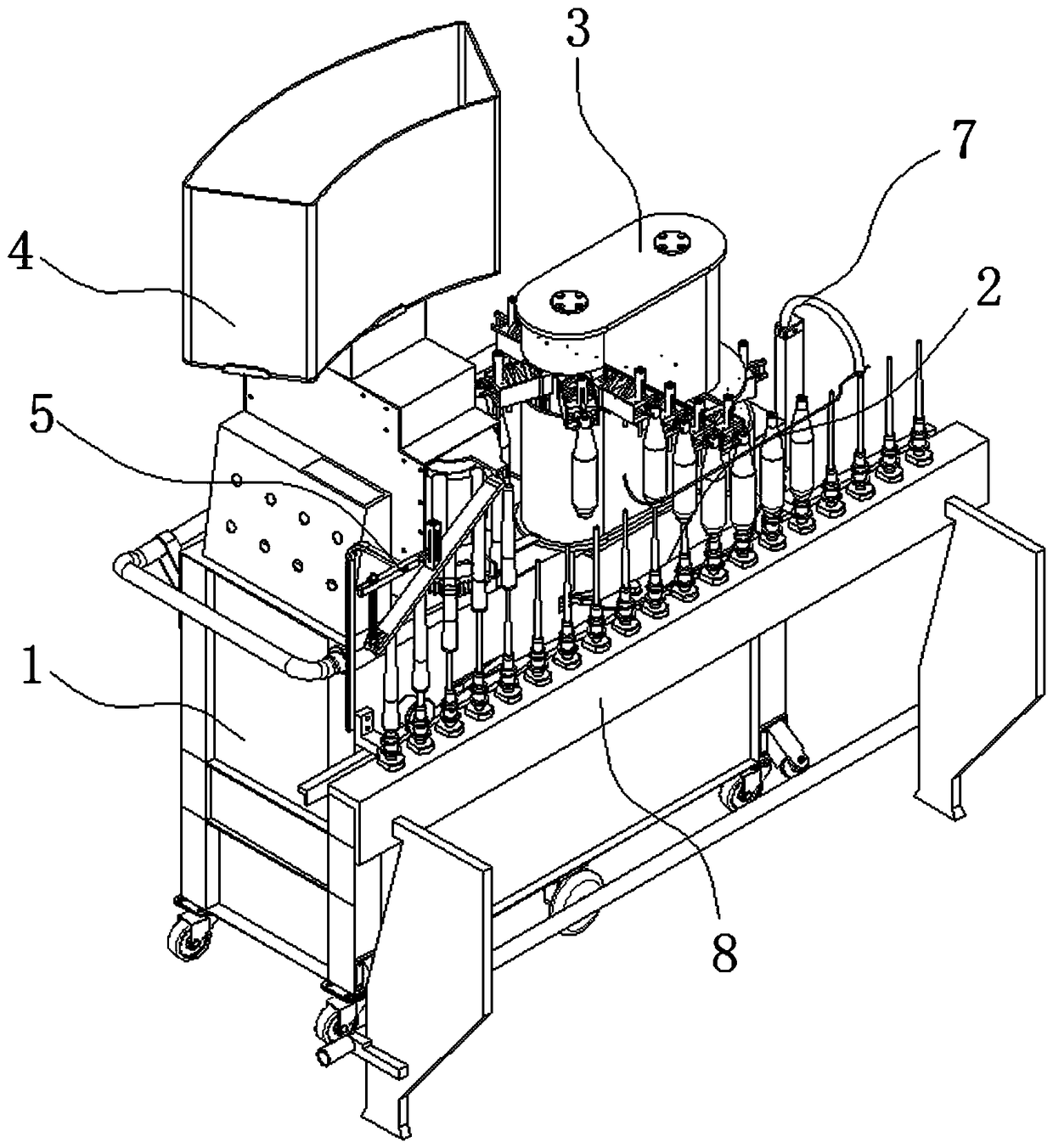

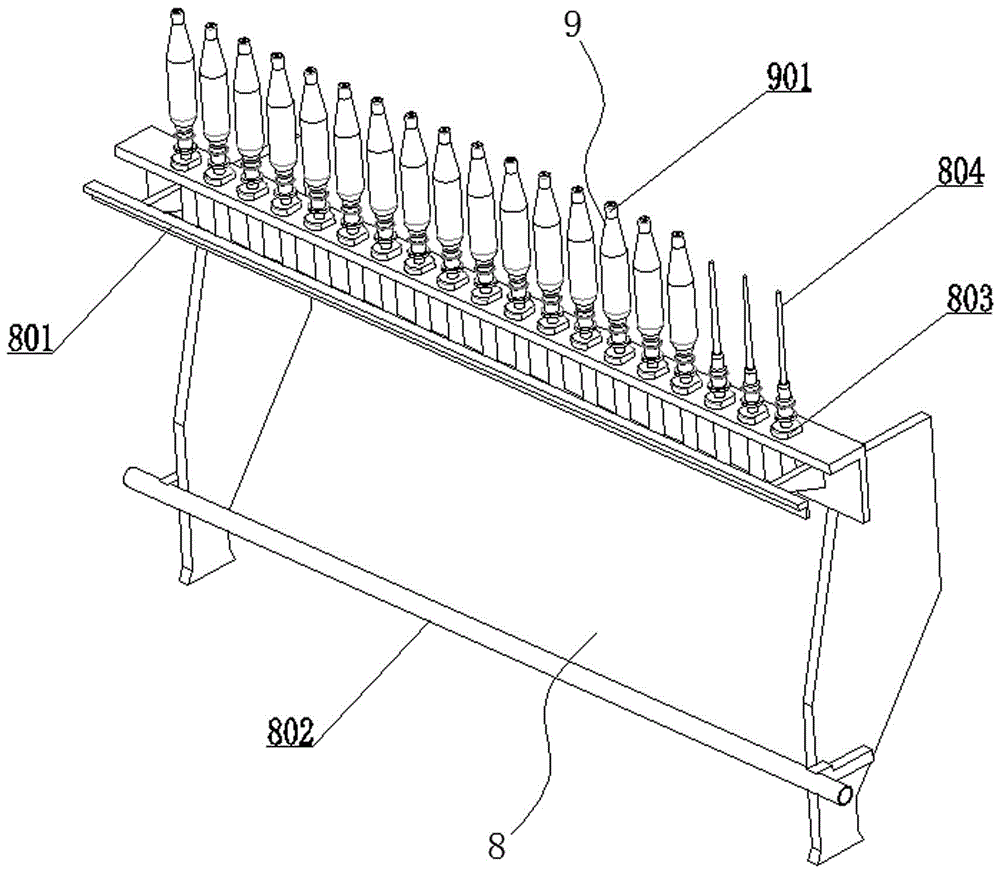

Worsted yarn doffer bobbin inserting device

The invention relates to a worsted yarn doffer tube inserting device. The bobbin inserting device comprises a bobbin inserting box, a bobbin material box, a bobbin material feeding conveying device and a bobbin insertion executing device. According to the worsted yarn doffer bobbin inserting device, the bobbin material box reciprocal shaking device is not necessary, and therefore the situation that the bobbin material box shakes reciprocally and vibrates to affect the doffer. The angle change of the bobbin in a controllable condition is achieved. After rotating by 180 degrees horizontally an S-shape is pushed to become the vertical status of 90 degrees. After the equal pitch synchronous displacement of a guide disk and a spindle, the spindle is accurately inserted. The worsted yarn doffer bobbin inserting device changes the bobbin angle change and insertion mode of the various current doffers.

Owner:荣德明

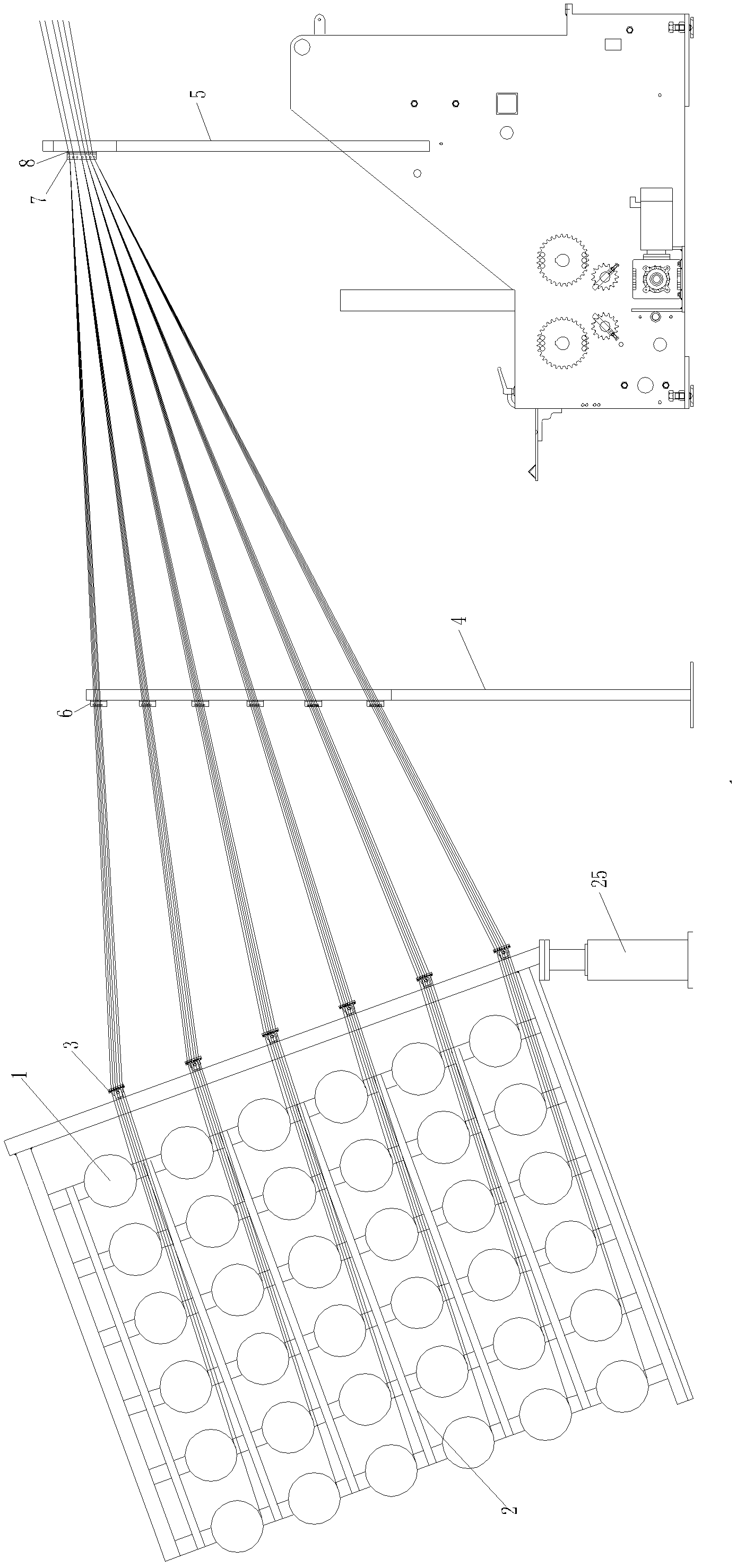

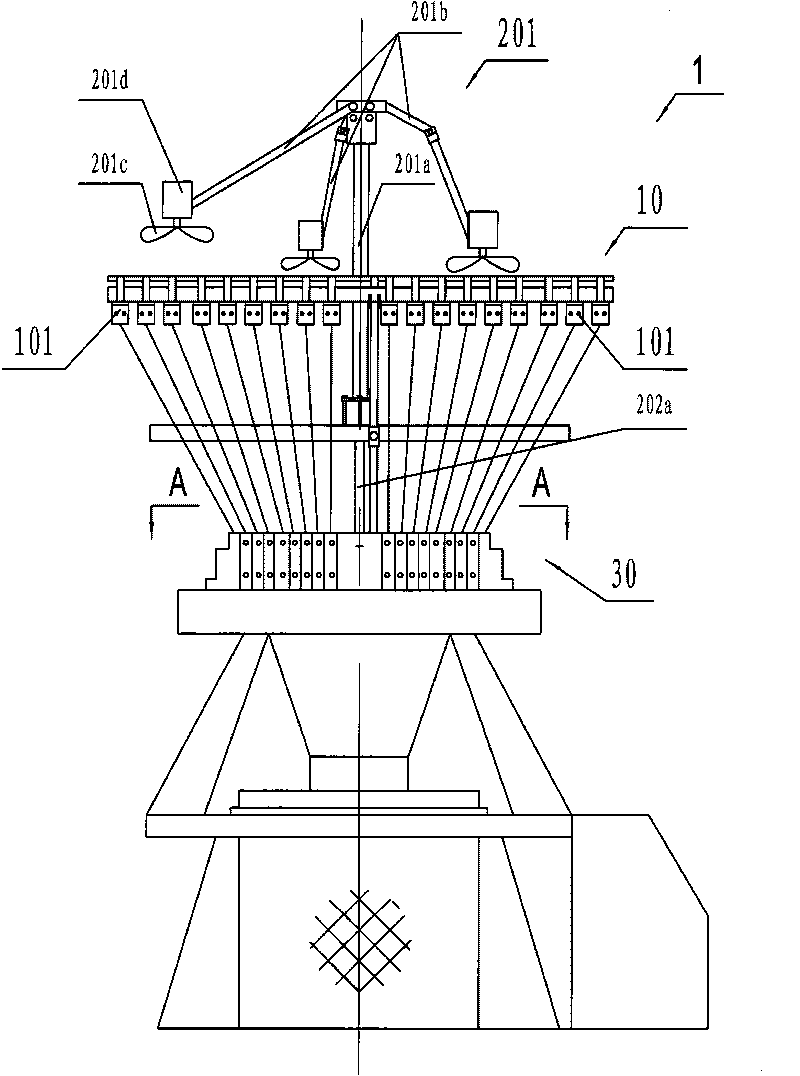

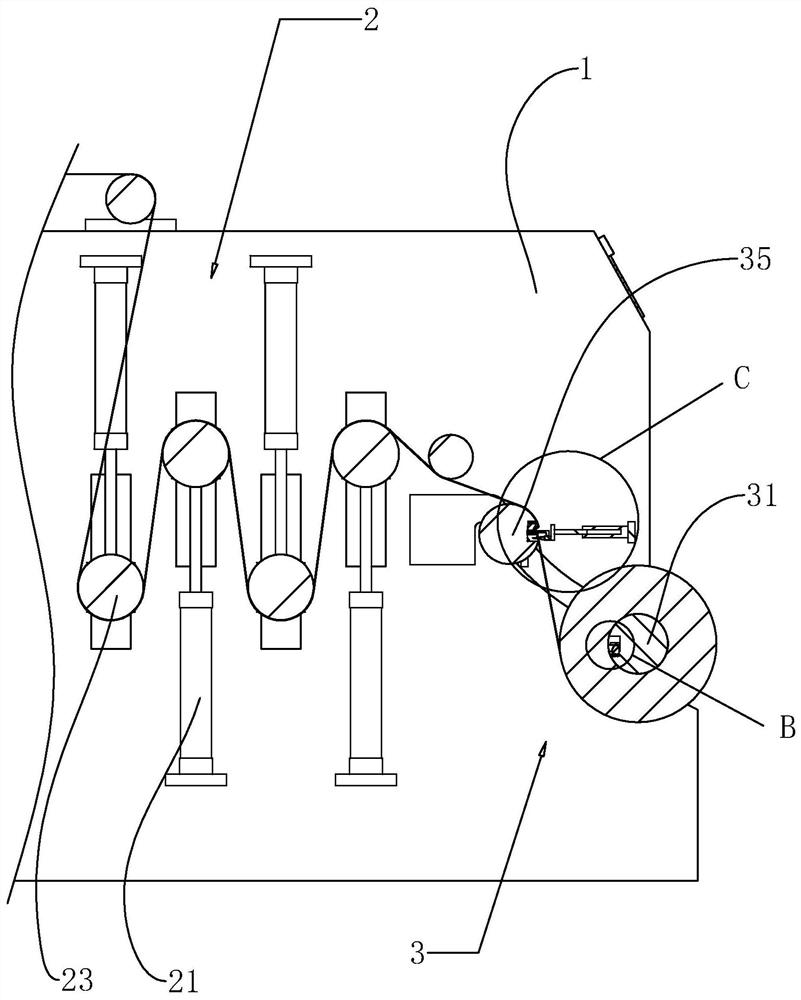

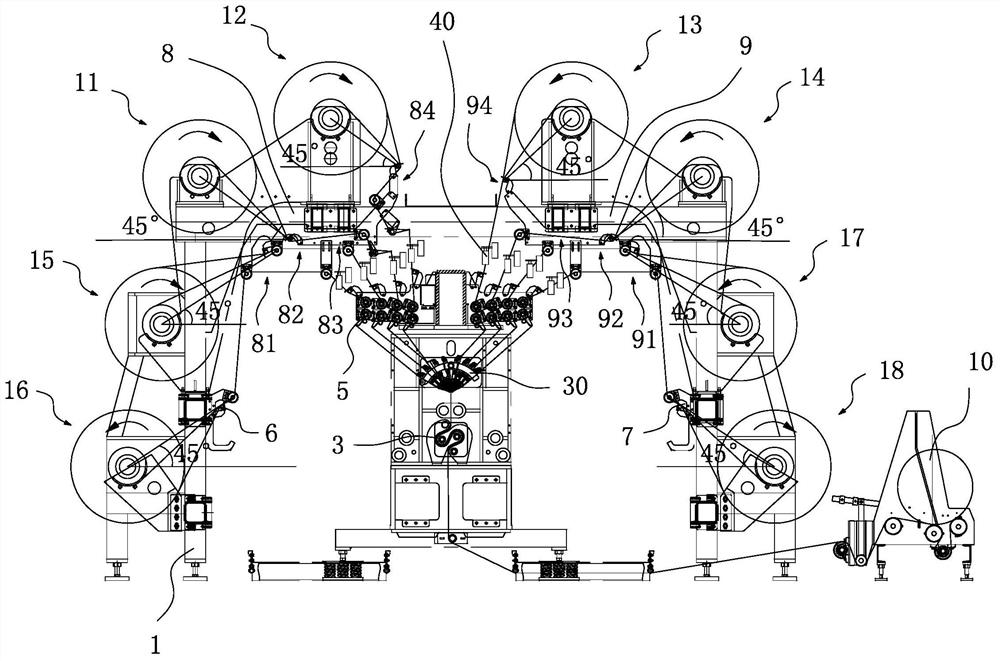

Warp knitting machine yarn path distributing system

PendingCN111778628AReduce high frequency vibrationGuarantee delivery qualityWarp knittingEngineeringStructural engineering

The invention relates to the field of textile machinery, in particular to a warp knitting machine yarn path distributing system, and mainly aims to solve the problem in the prior art that yarn path distribution is not reasonable to cause that the warp knitting quality of warp knitting fabric is poor. The warp knitting machine yarn path distributing system comprises a rack, seven or eight rotary shafts rotatably arranged on the rack, a drive motor driving the rotary shafts to rotate, and a warp knitting device; a plurality of pan heads are arranged on each of the rotary shafts; a yarn guiding compensating mechanism is arranged at the upper part of the warp knitting device; the rack covers the outer side of the warp knitting device; the rotary shafts are arranged on the rack in parallel in the front-rear direction; eight yarn placing areas including a first yarn placing area, a second yarn placing area, a third yarn placing area, a fourth yarn placing area, a fifth yarn placing area, a sixth yarn placing area, a seventh yarn placing area and an eighth yarn placing area for mounting all rotary shafts are arranged on the rack; and a yarn tension adjusting device for adjusting the tension of the yarn on each yarn placing area is arranged between the rack and the yarn guiding compensating mechanism.

Owner:JINJIANG PENGTAI MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com