High-speed sealing integrated lower roller bearing

An integrated, bearing technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of difficult oiling operation, increased friction resistance, and large friction coefficient, so as to improve textile quality, reduce friction resistance and extend bearing life Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

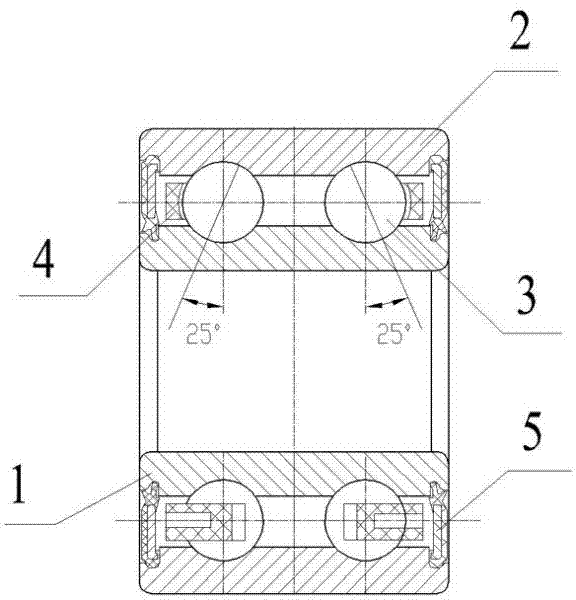

[0024] Such as figure 2 As shown, a high-speed sealed integrated bottom roller bearing includes a bearing inner ring 1, a bearing outer ring 2, steel balls 3, a cage 4 and a dustproof sealing ring 5. The inner wall of the bearing outer ring 2 is provided with a plurality of grooves, and the outer wall of the bearing inner ring 1 is correspondingly provided with a plurality of grooves, thereby forming a plurality of raceways, and each raceway holds several steel balls 3, and the steel balls 3 are separated by The cages 4 are equidistantly spaced, and the multiple raceways are arranged symmetrically along the axis of symmetry of the bearing. The number of steel balls is variable, depending on the size. The design of the above-mentioned raceway enables the bearing to withstand a certain degree of radial force, thereby being able to withs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com