Dual-driving system and driving method of piezoelectric ceramic driving sheet for needle selector

A piezoelectric ceramic drive, piezoelectric ceramic sheet technology, applied in the field of needle selectors, can solve the problems of increased equipment cost, low textile efficiency, piezoelectric ceramic sheets not working, etc., to improve safety and service life, improve textile Efficiency and quality, the effect of increasing swing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

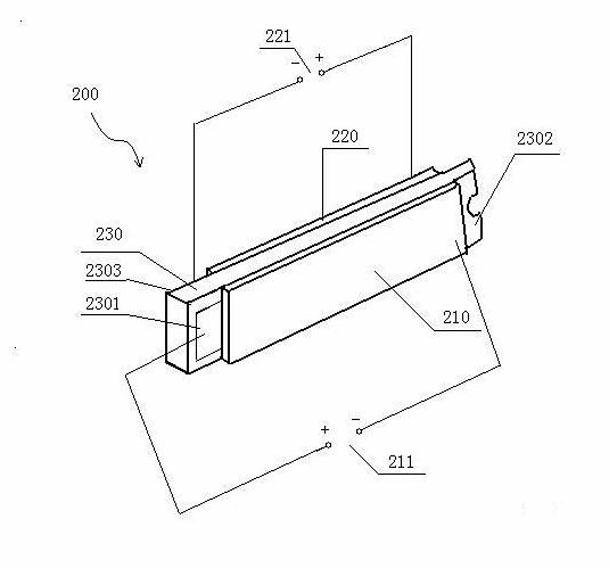

[0037] The B-203 piezoelectric ceramic sheet produced by Jiangsu Yilong New Energy Technology Development Co., Ltd. is used, with a thickness of 0.25mm. according to image 3 A positive voltage of 190V is applied to the piezoelectric ceramic sheet 210 and a negative voltage of 36V is applied to the piezoelectric ceramic sheet 220 . The force is measured by hanging a weight at the tip of the needle selection, and the maximum mass of the weight applied when the tip of the selection needle does not sink is 8.8 grams.

Embodiment 2

[0039] The B-203 piezoelectric ceramic sheet produced by Jiangsu Yilong New Energy Technology Development Co., Ltd. is used, with a thickness of 0.25mm. according to image 3 A positive voltage of 190V is applied to the piezoelectric ceramic sheet 210 and a negative voltage of 48V is applied to the piezoelectric ceramic sheet 220 . The force is measured by hanging a weight at the tip of the needle selection, and the maximum mass of the weight applied when the tip of the selection needle does not sink is 9.2 grams.

Embodiment 3

[0044] The B-203 piezoelectric ceramic sheet produced by Jiangsu Yilong New Energy Technology Development Co., Ltd. is used, with a thickness of 0.25mm. according to image 3 A positive voltage of 160V is applied to the piezoelectric ceramic sheet 210 and a negative voltage of 48V is applied to the piezoelectric ceramic sheet 220 . The force is measured by hanging a weight at the tip of the needle selection, and the maximum weight applied when the tip of the selection needle does not sink is 8.5g.

[0045] From the results measured in Example 3 and Comparative Example 1, it can be known that the needle selector piezoelectric ceramic drive plate dual drive system of the present invention can apply a lower forward voltage than the prior art, but it can also be applied by applying a reverse voltage. Similar or even greater swing dynamics are obtained. This result shows that the piezoelectric ceramic double drive system of the needle selector in the present invention can reduce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com