Wheel hanging and tightening type wiring stitching machine for flexible heating blanket body and manufacturing equipment

A wheel-hanging heating blanket technology, applied in the production field of flexible heating appliances, can solve the problems of no automatic covering, failure to achieve automatic production equipment, and undescribed fiber blanket material bonding technology, etc., to avoid mechanical The probability of damage to the heating cord, the reduction of labor intensity and production time, and the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

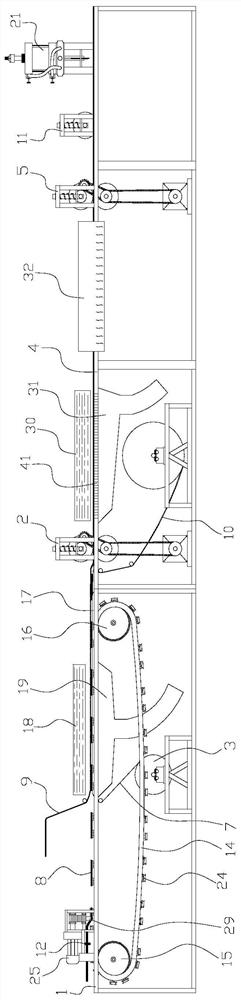

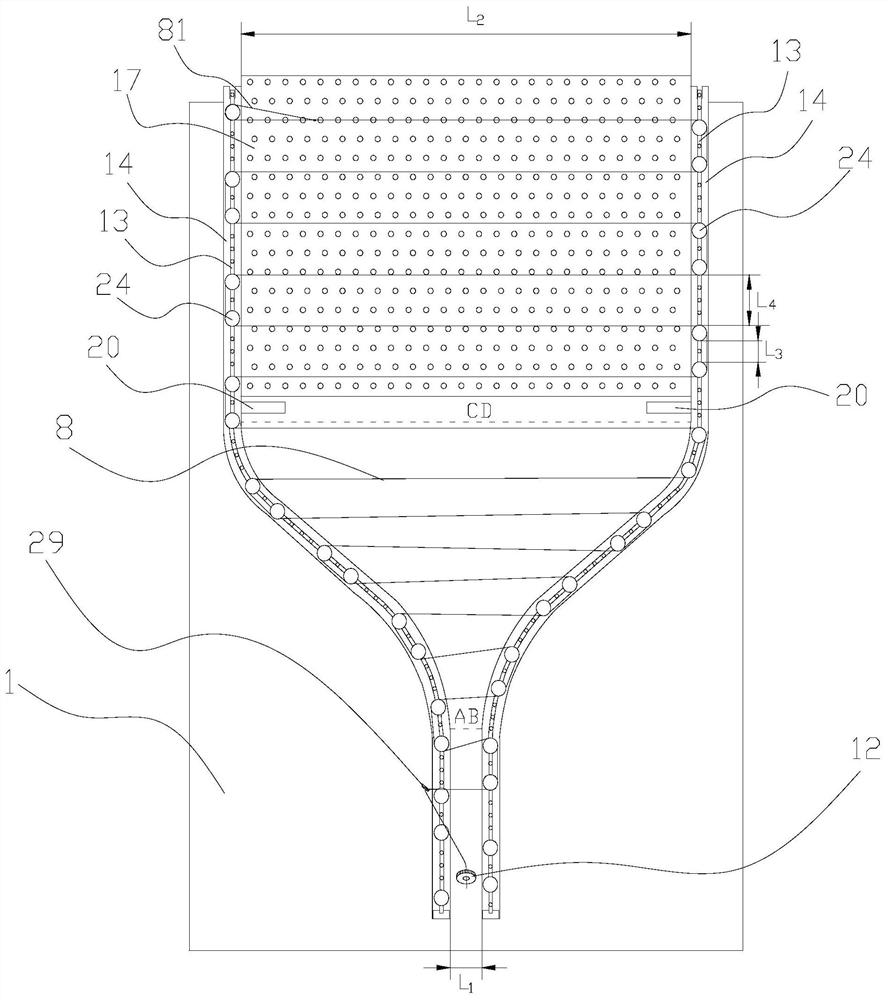

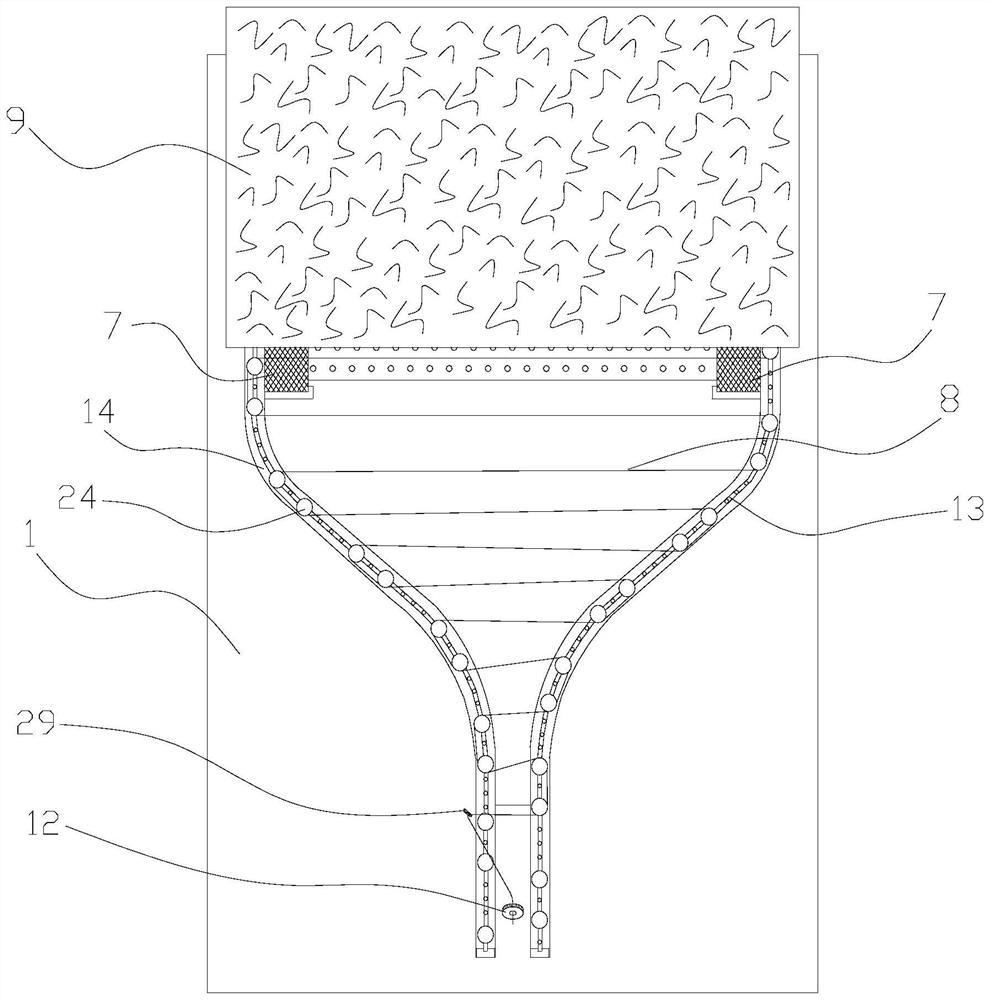

[0025] Embodiment 1: as Figure 1 to Figure 6 As shown, the wheel-hanging tension-type wiring stitching machine for the flexible heating blanket body in this embodiment includes a wheel-hanging tension wiring mechanism, a wiring machine 1, a first synchronous tension roller mechanism 2, and two fixing belt frames 3 , spunlace drying machine table 4, spunlace drying mechanism and second synchronous tension roller mechanism 5. The wheel hanging tension wiring mechanism is installed on the wiring machine 1, the fixed belt frame 3 is located under the wiring machine 1, the spunlace drying mechanism is installed on the spunlace drying machine 4, and the first synchronous tension roller mechanism 2 is located on the Between the wheel-hanging tensioned wiring mechanism and the spunlace drying mechanism, the second synchronous tension roller mechanism 5 is located behind the spunlace drying mechanism.

[0026] The wheel hanging type wiring mechanism includes a wire manager 12, a pend...

Embodiment 2

[0033] Embodiment 2: The structure of the wheel-hanging type wiring stitching machine for the flexible heating blanket body in this embodiment is the same as that in Embodiment 1.

[0034] Such as Figure 7 As shown, the manufacturing equipment of the flexible heating blanket body in this embodiment includes a blanket body winding mechanism 6, a cutting and trimming mechanism 11 and the above-mentioned wheel-hanging stretch type wiring stitching machine, and the cutting and trimming mechanism 11 is installed in the spunlace oven. On the drying machine table 4 and located behind the second synchronous tension roller mechanism 5, the blanket winding mechanism 6 is located behind the cutting and trimming mechanism 11, and the cutting and trimming mechanism 11 pulls the output flexible heating blanket body to the second synchronous tension roller mechanism 5 After trimming, the flexible heating blanket body after trimming enters the blanket body winding mechanism 6, and the blanke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com