A dual-power bidirectional drive circuit for piezoelectric ceramic jacquard combs

A piezoelectric ceramic, two-way drive technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of reduced service life and inability to have both , to reduce the use and production costs, extend the service life, and meet the needs of Jacquard performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

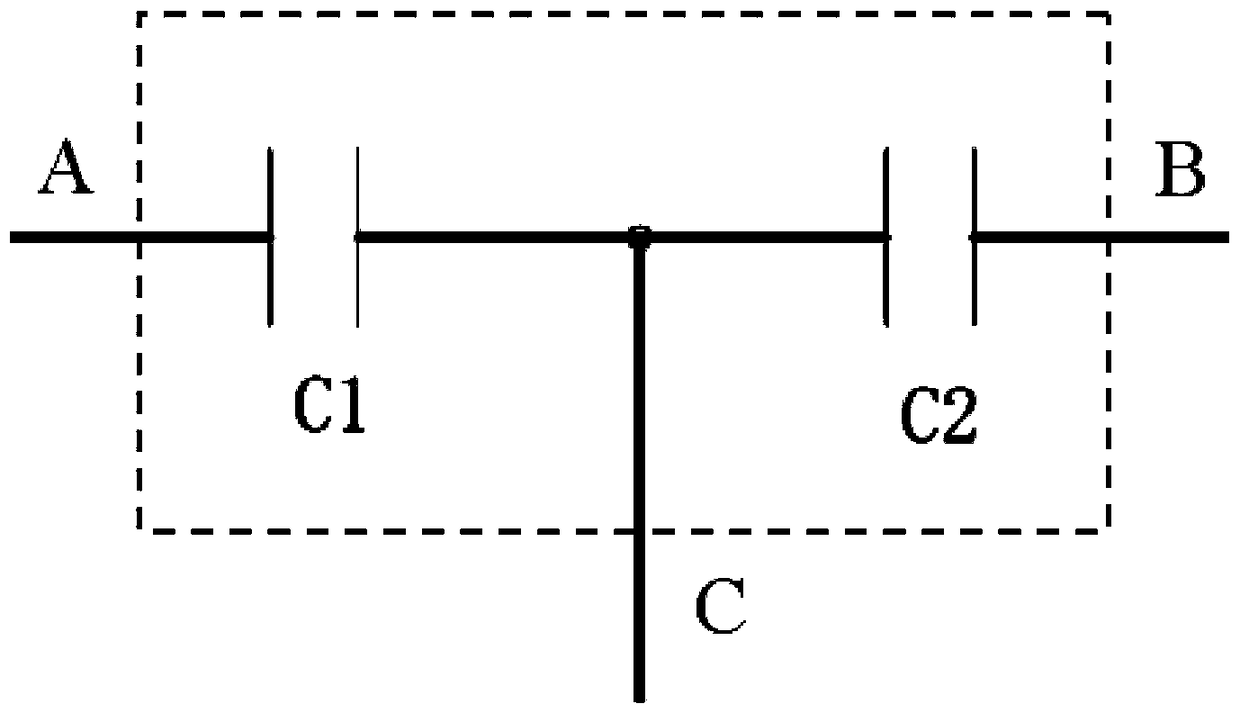

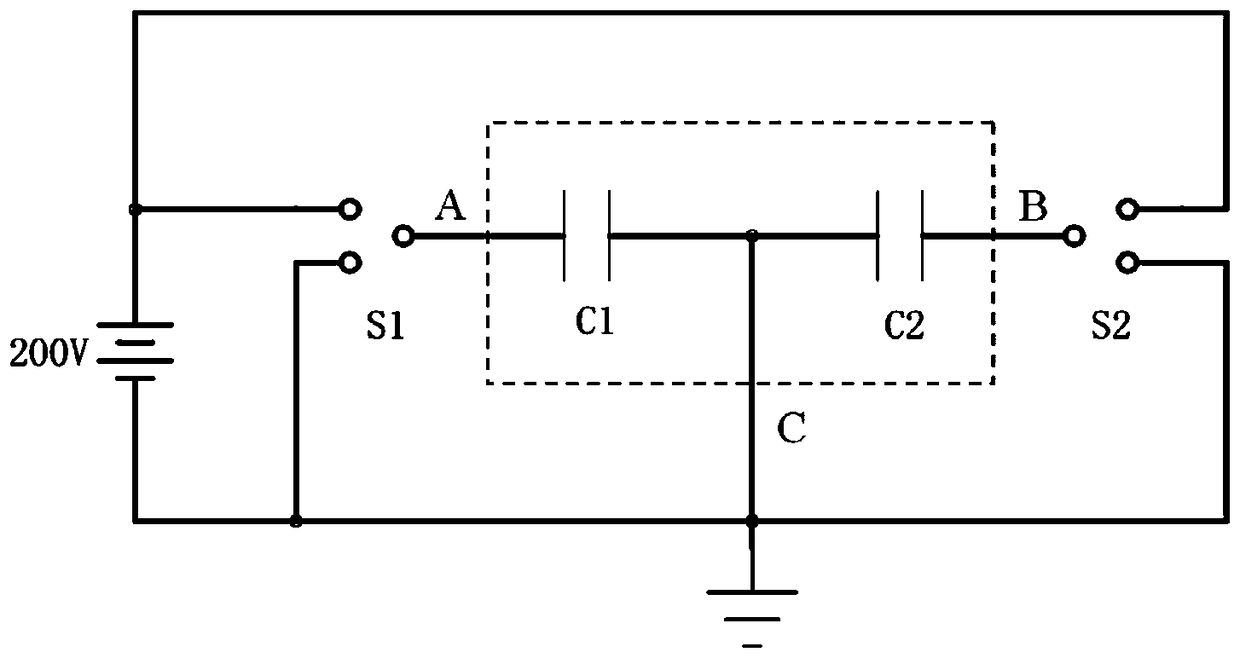

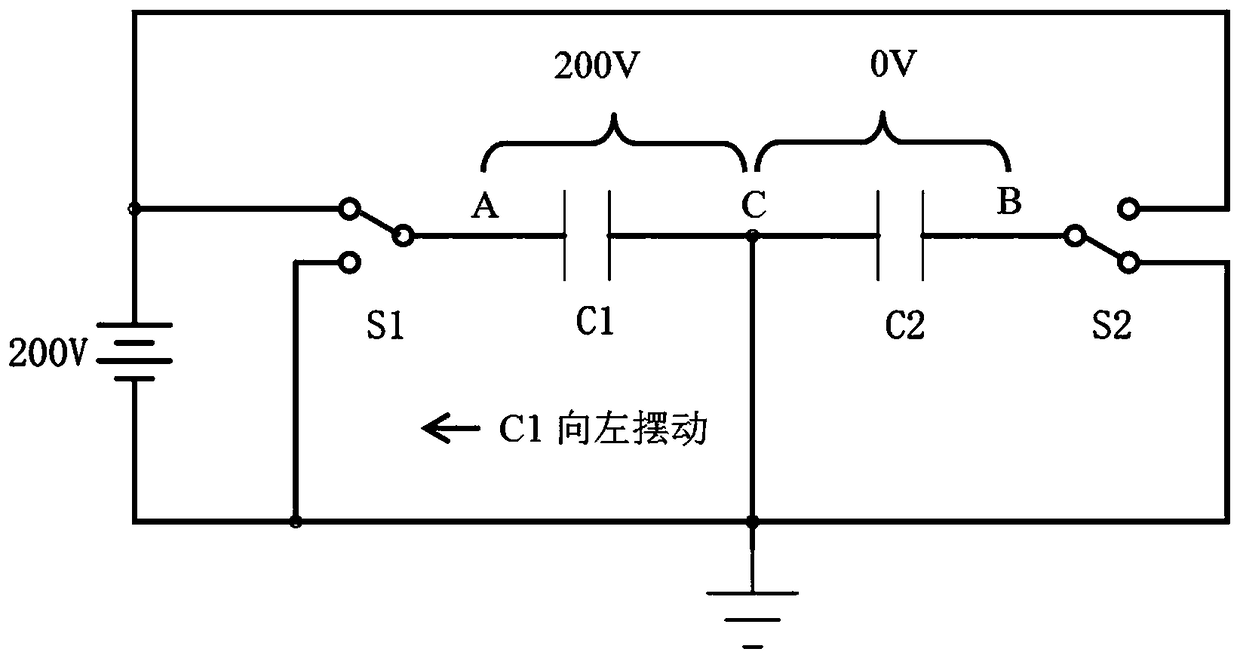

[0024] refer to figure 1 . A dual-power bidirectional drive circuit for piezoelectric ceramic jacquard combs, comprising a power supply VCC1, a power supply VCC2, a piezoelectric ceramic chip C1, a piezoelectric ceramic chip C2, a control switch circuit S1, and a control switch circuit S2, the control switch Both the circuit S1 and the control switch circuit S2 include two input terminals and an output terminal, and the first input terminal of the control switch circuit S1 and the first input terminal of the control switch circuit S2 are connected in parallel to the positive pole of the power supply VCC1; The second access terminal of the control switch circuit S1 and the second access terminal of the control switch circuit S2 and the negative pole of the power supply VCC1 are connected in parallel to the negative pole of the power supply VCC2; the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com