Winding device with high retentivity for spandex yarn production and processing

A winding device and technology of spandex yarn, which is applied in the field of spandex yarn production, can solve the problems that spandex yarn cannot be accumulated and wound at a fixed position, the tension of spandex yarn cannot be adjusted, and there is no reciprocating cycloid, etc., so as to increase adjustability , Guarantee the tightness and avoid the effect of off-line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

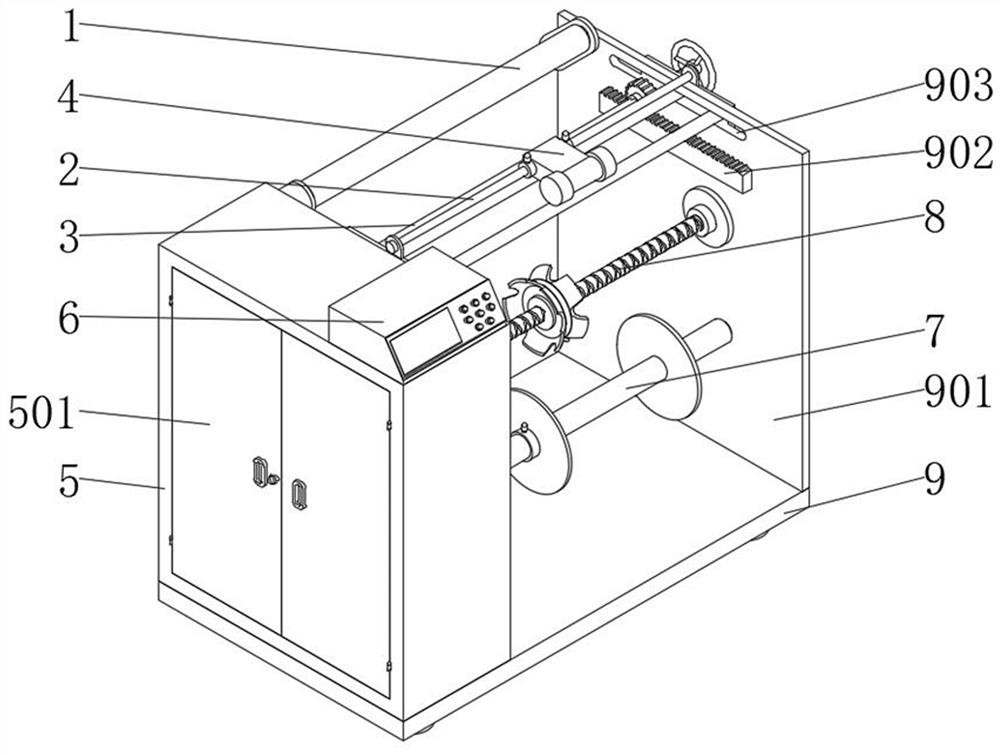

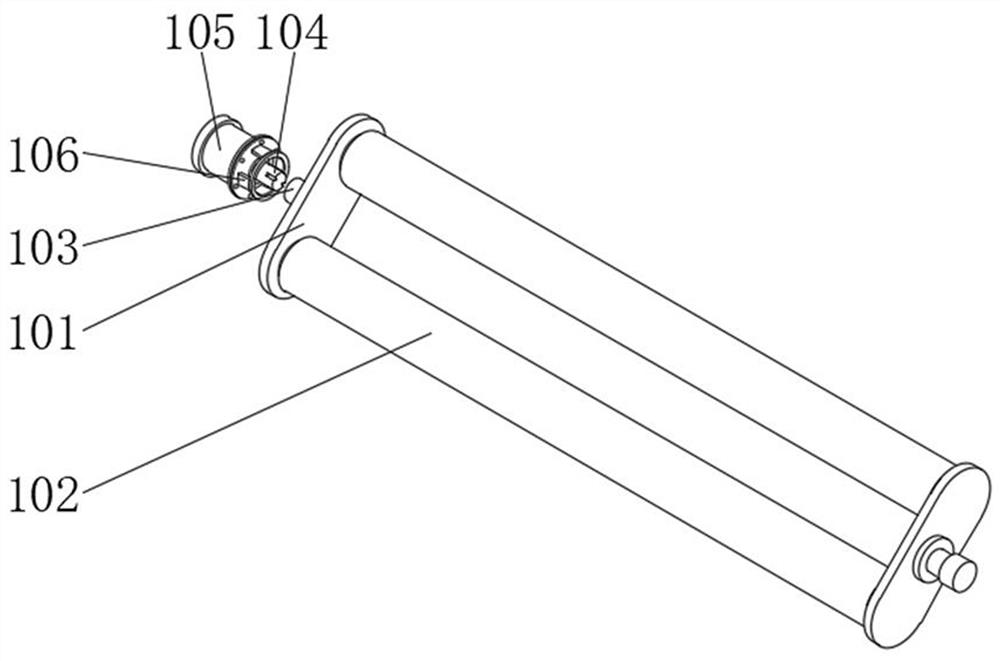

[0035] see Figure 1-8 , a winding device for the production and processing of spandex yarn with strong holding force proposed by the present invention, comprising an elastic adjustment assembly 1, an installation box 5, a cycloid assembly 8 and a bottom plate 9, a side plate 901 is installed on the top side of the bottom plate 9, Bottom plate 9 can provide installation position for installation box 5 and side plate 901, can provide installation position for tightness adjustment assembly 1, adjustment frame 2, winding assembly 7, cycloid assembly 8 through installation box 5 and side plate 901, side plate 901 There is a chute 903 inside, and the side plate 901 can move the adjusting frame 2 through the internal chute 903, which is convenient for the adjusting frame 2 to move horizontally, so that it is convenient to adjust the outlet angle of the spandex yarn according to the winding needs of the spandex yarn. The inner side of the side plate 901 is equipped with a gear seat 9...

Embodiment 2

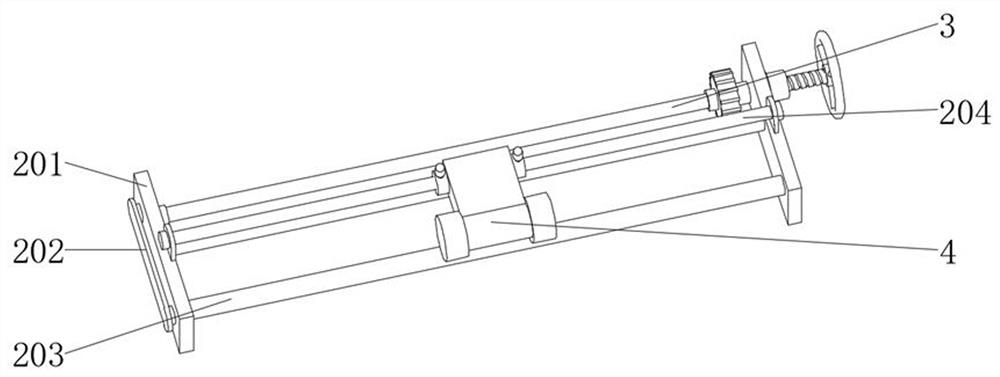

[0037] see Figure 2-4 , a winding device for the production and processing of spandex yarn with strong holding force proposed by the present invention. Compared with Embodiment 1, this embodiment also includes that the adjustment frame 2 includes two sets of limit rods 203, and the two ends of the limit rod 203 An adjusting plate 201 is installed, and one side of the adjusting plate 201 is equipped with a moving plate 202, and the moving plate 202 can be movably installed in the installation groove on the inner wall of the installation box 5, and the top of the adjusting plate 201 is equipped with a shaft, and the top of the adjusting plate 201 passes through the shaft. The installation rod 204 is installed on the part, the inside of the adjustment plate 201 is installed with the adjustment rod 3, the outside of the adjustment rod 3 is equipped with a gear part 301, and the gear part 301 is meshed with the gear seat 902, and one end of the adjustment rod 3 is equipped with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com