Fine spinning doffer imbedding force eliminating device

A technology of fitting force and doffing machine, which is applied in the direction of textiles and papermaking, and can solve problems such as inability to solve the fitting force between the spindle rod and the bobbin, time-consuming and laborious, and inability to effectively insert vertically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the drawings and embodiments.

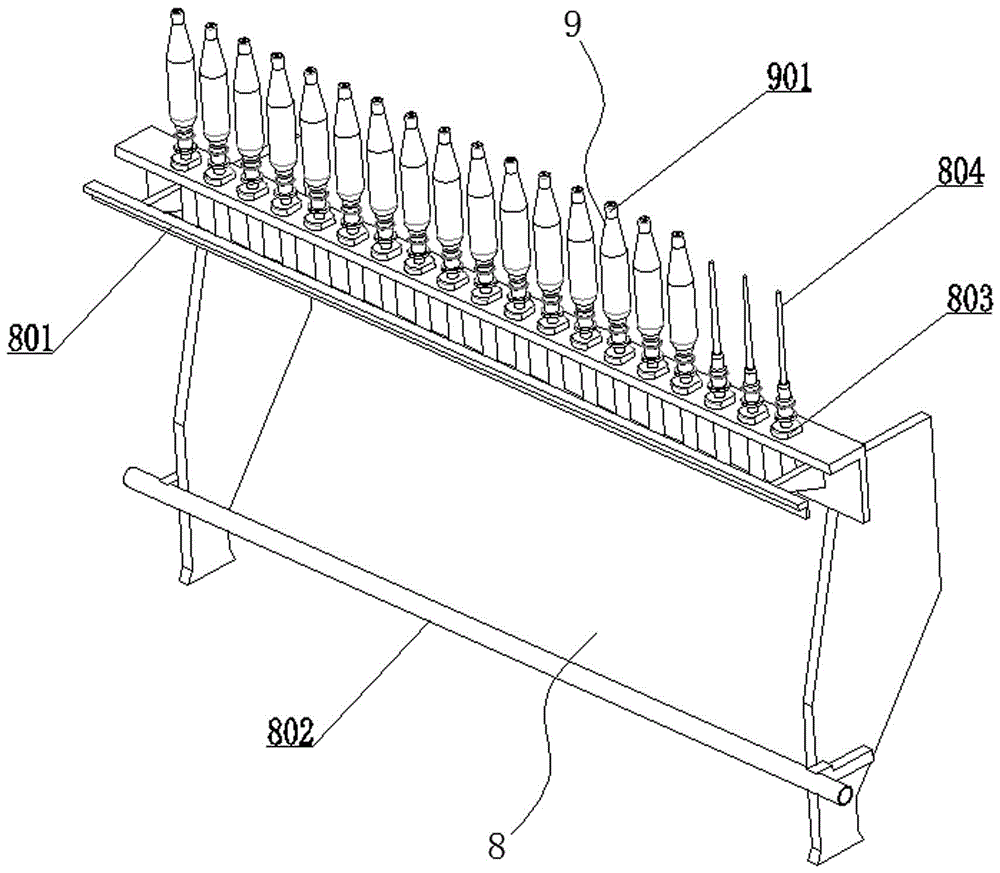

[0050] figure 1 Shown: on the front side of the worsted spinning machine, a number of spindle seats 803 are uniformly distributed along the length of the worsted spinning machine 8, the spindle rod 804 is threaded on the spindle seat 803, and the bobbin 901 of the bobbin 9 is inserted into the spindle On the rod 804, the upper and lower creels 801, 802 are set up and down along the length of the frame on the front side of the 8 spindle seat 803 of the spinning machine.

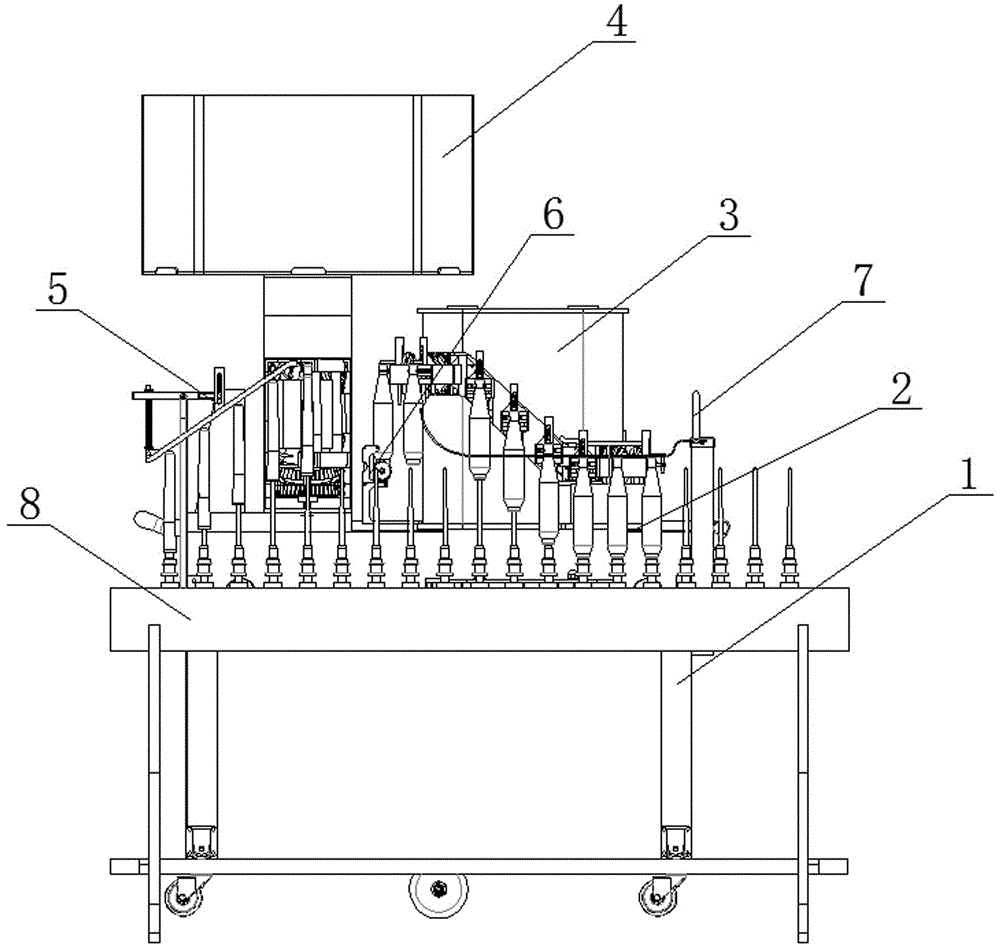

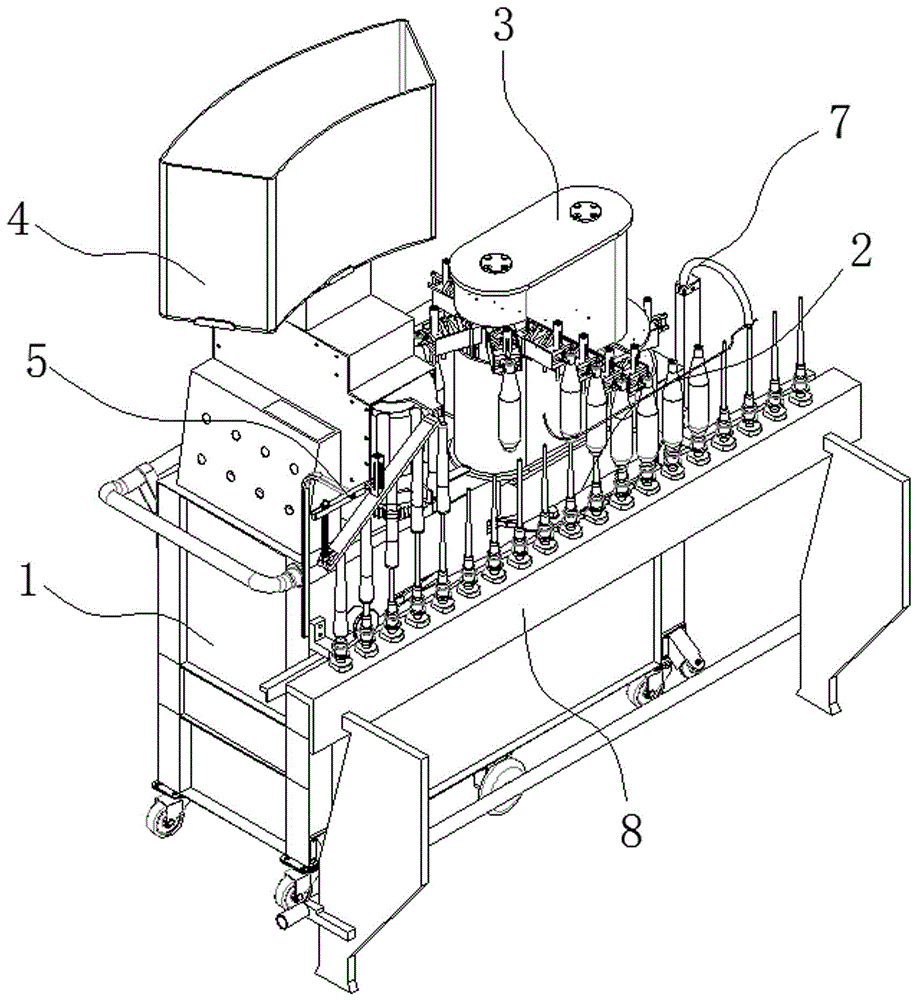

[0051] figure 2 , 3 Shown: the doffer of the present invention corresponds to the worsted spinning machine 8 which feeds from left to right, Figure 4 , 5 Shown: the doffing machine of the present invention includes the frame moving trolley 1, the insertion and extraction tube positioning power device 2, the extraction device 3, the insertion device 4, the tube pressing device 5, the cutting compound yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com