Textile roving frame flyer

A roving frame and flyer technology, applied in textiles and papermaking, etc., can solve problems affecting people's health, frequent heater work, waste of resources, etc., achieve good humidification effect, easy to use and promote, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

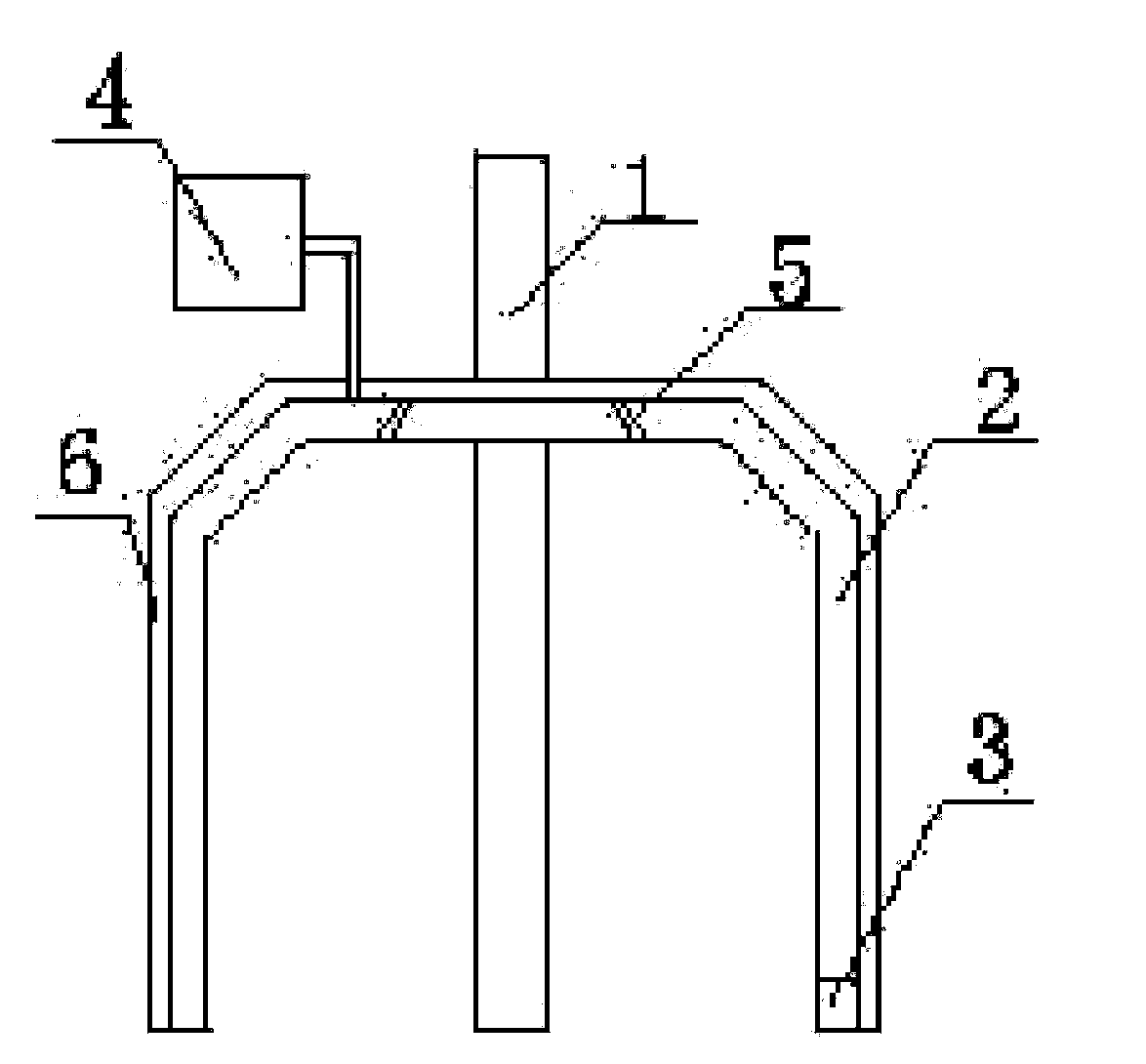

[0017] like figure 1 figure 2 As shown, a kind of spinning roving flyer for textile includes a rotating shaft 1, a spindle casing 2, a yarn guide block 3, a humidifier 4 and an oblique through hole 5, the rotating shaft 1 is fixedly connected with the spindle casing 2, and one end of the spindle casing 2 is provided with a guide The yarn block 3 is fixedly connected with the humidifier 4 above the spindle shell 2, and two oblique through holes 5 are provided on the spindle shell 2, and the humidifier 4 is communicated with the oblique through holes 5;

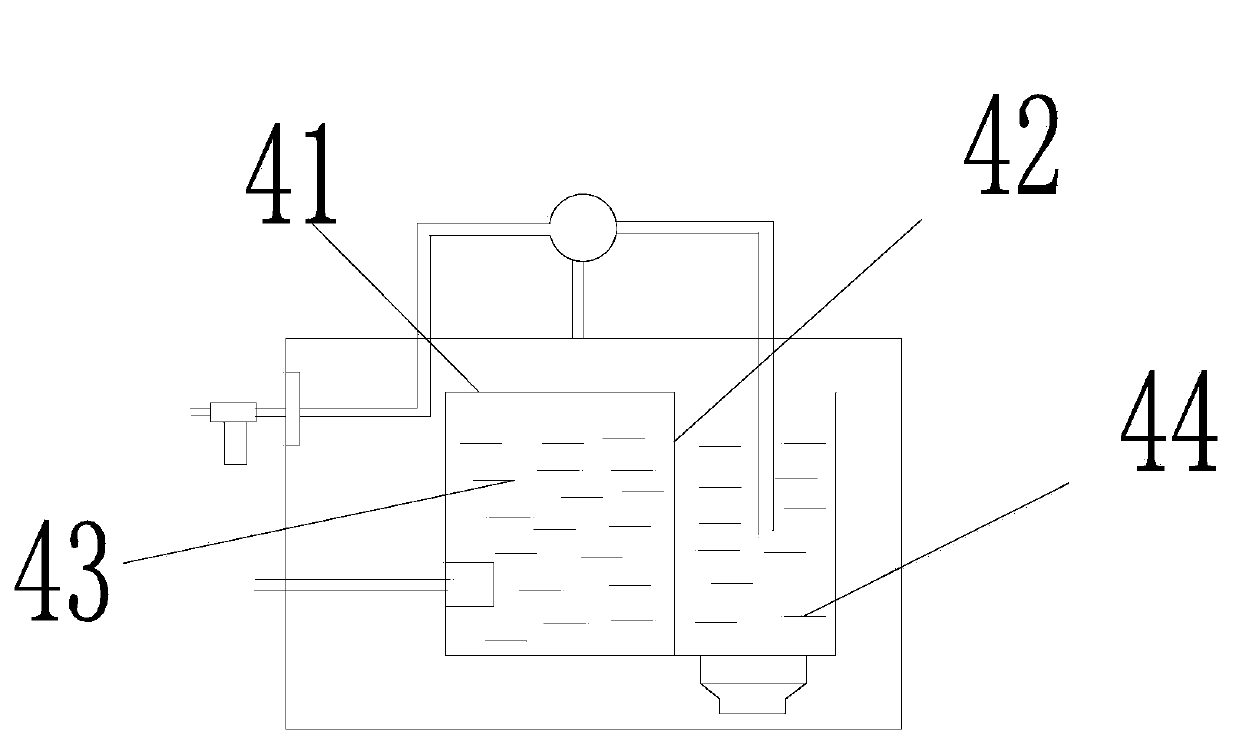

[0018] The humidifier 4 includes a water tank body 41. The water tank body 41 is divided into a water storage tank 43 and a humidification water tank 44 by a partition plate 42 in the box. The tank 43 is communicated with the water inlet pipe, the bottom of the humidification water tank 44 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com