Bobbin blanking and conveying device of fine spinning doffing machine

A transmission device and doffing machine technology, applied in textiles and papermaking, etc., can solve problems such as difficulty in adapting, time-consuming, labor-intensive, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with drawings and embodiments.

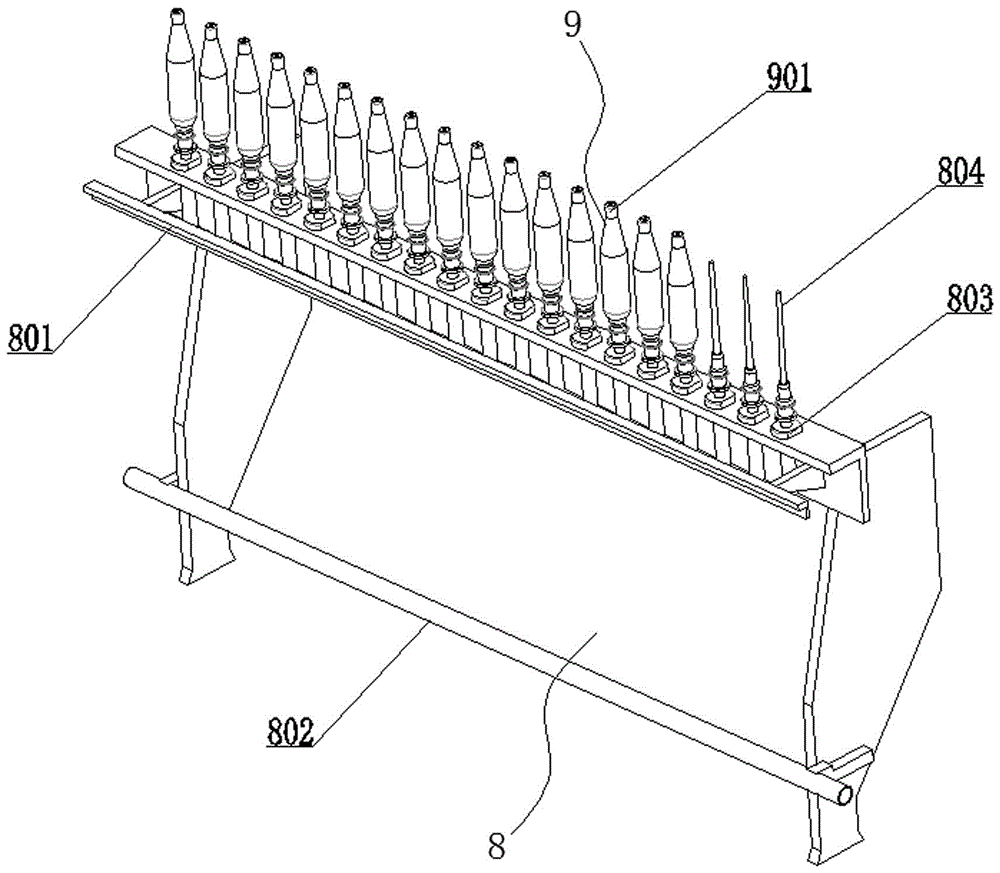

[0050] figure 1 Shown: the front part of the spinning machine, the spinning machine 8 is evenly distributed with a plurality of spindle bases 803 along its length direction, the spindle bar 804 is connected to the spindle bases 803, and the bobbin 901 of the bobbin 9 is embedded in the spindle On the bar 804, upper and lower doffing frames 801, 802 are arranged up and down along its length direction on the frame of the 8 spindle bases 803 front sides of the spinning machine.

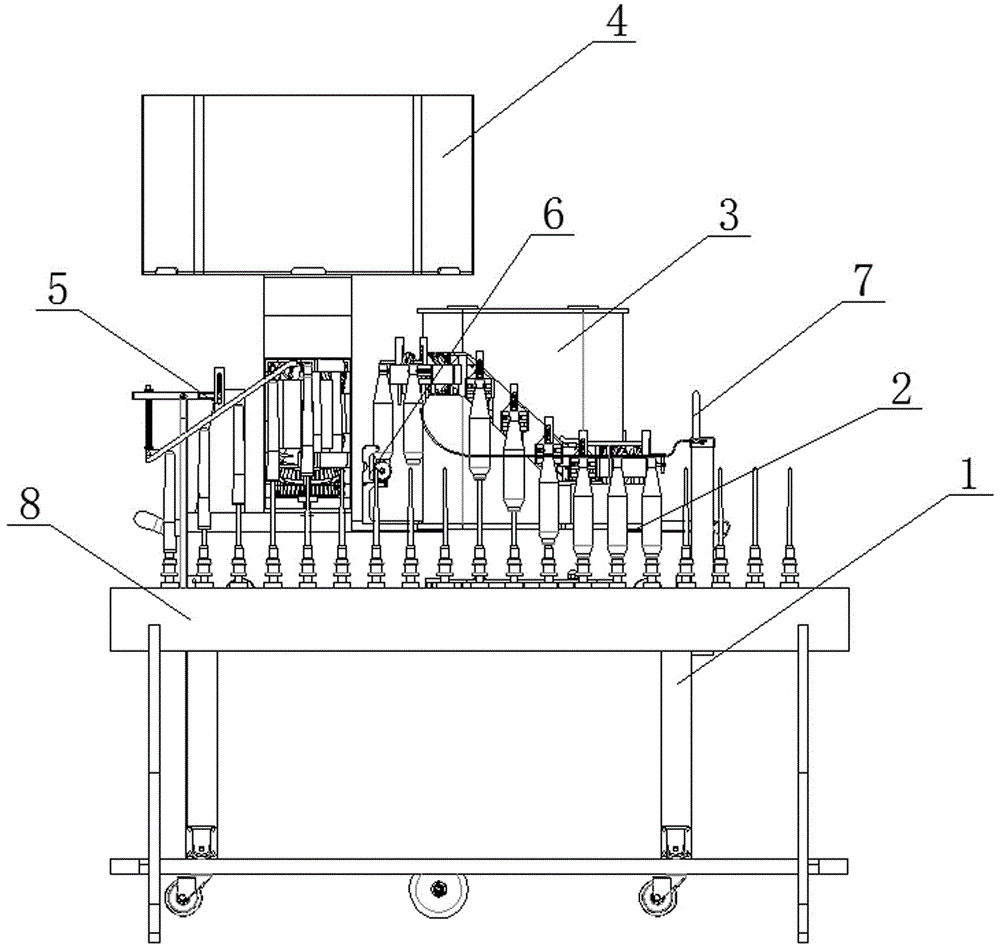

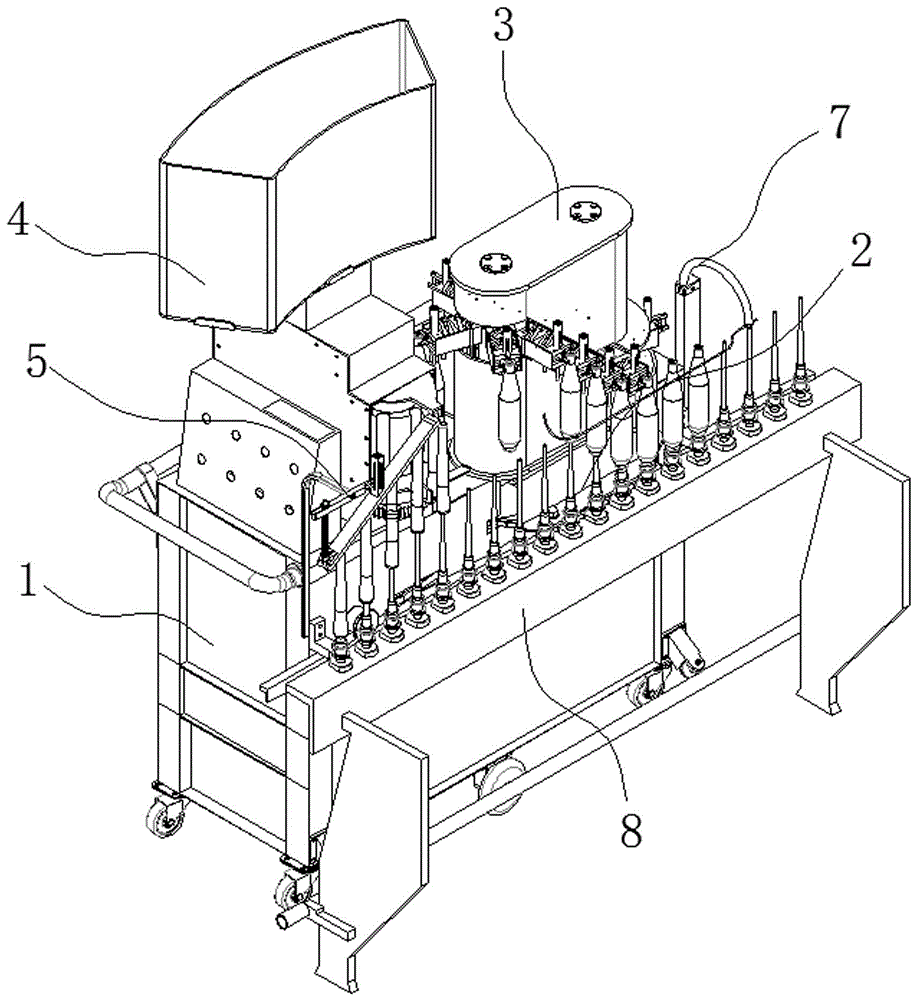

[0051] figure 2 , 3 Shown: doffing frame of the present invention corresponds to spinning machine 8 and feeds from left to right, Figure 4 , 5 As shown: the doffing machine of the present invention includes a frame mobile trolley 1, a tube insertion and extraction positioning power device 2, a tube removal device 3, a tube insertion device 4, a tube pressing device 5, a compound yarn cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com