Warp knitting machine yarn path distributing system

A distribution system and warp knitting machine technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of unreasonable distribution of yarn paths and poor warp knitting quality of warp knitted fabrics, and improve service life and stability. Good, avoid the effect of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

[0022] The embodiment of the present invention is:

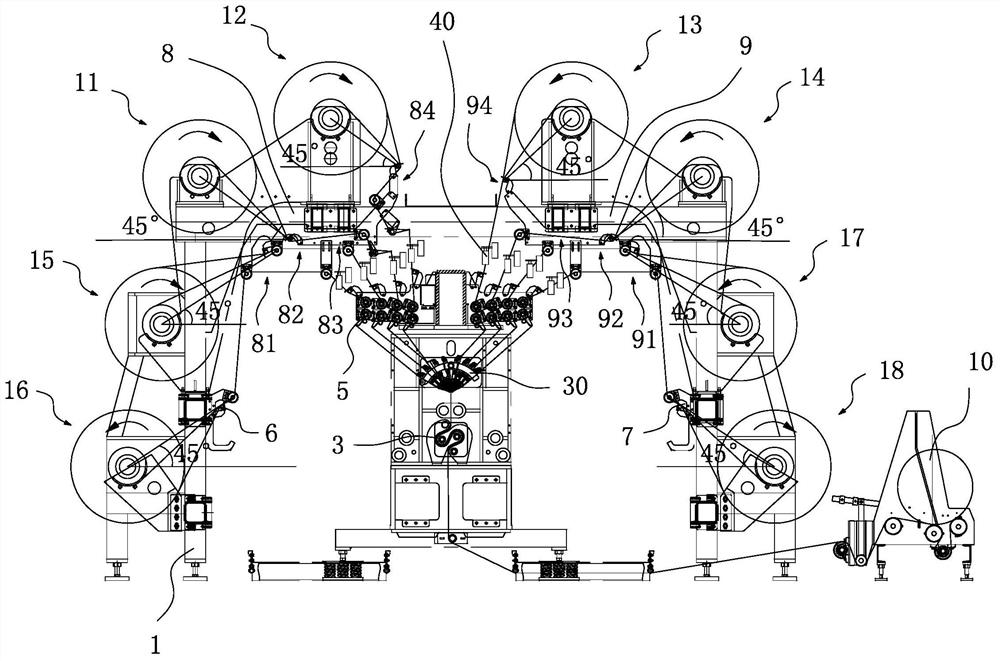

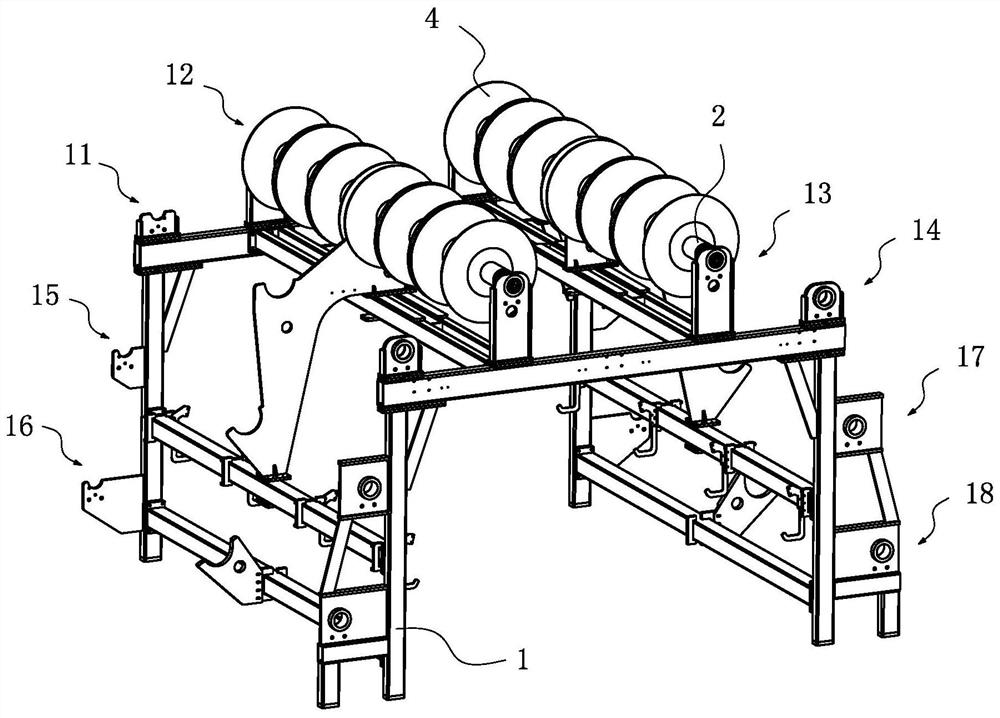

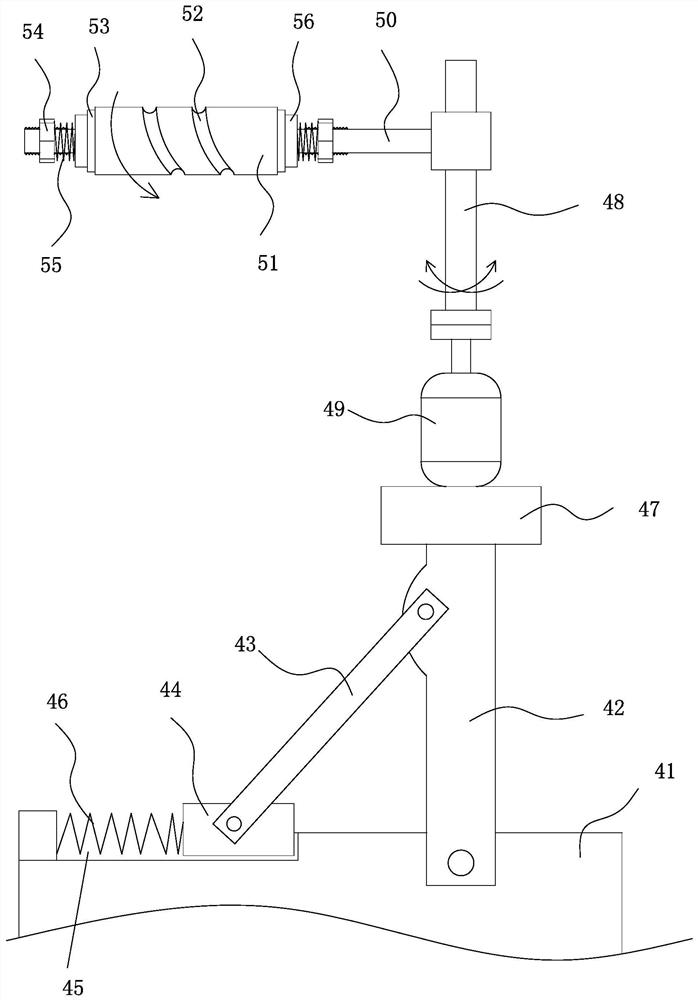

[0023] refer to figure 1 and figure 2As shown, a yarn path distribution system of a warp knitting machine includes a frame 1, eight rotating shafts 2 rotatably arranged on the frame 1, a driving motor (not shown in the figure) for driving the rotating shafts 2 to rotate, and a warp knitting machine. Device 3, the warp knitting machine has a bar assembly 30, each of the rotating shafts 2 is provided with six disk heads 4, the upper part of the warp knitting device 3 is provided with a yarn guide compensation mechanism 5, which defines the direction along the warp knitting device 3 The length direction of the warp knitting device 3 is defined as the front-rear direction, the height direction of the warp knitting device 3 is defined as the up-down direction, and the width direction of the warp kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com