Electromechanical machining clamp for different workpieces

A workpiece fixture, electromechanical technology, applied in metal processing mechanical parts, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to achieve stable clamping, side slip of the clamping surface, etc., to improve practicability, facilitate clamping, Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

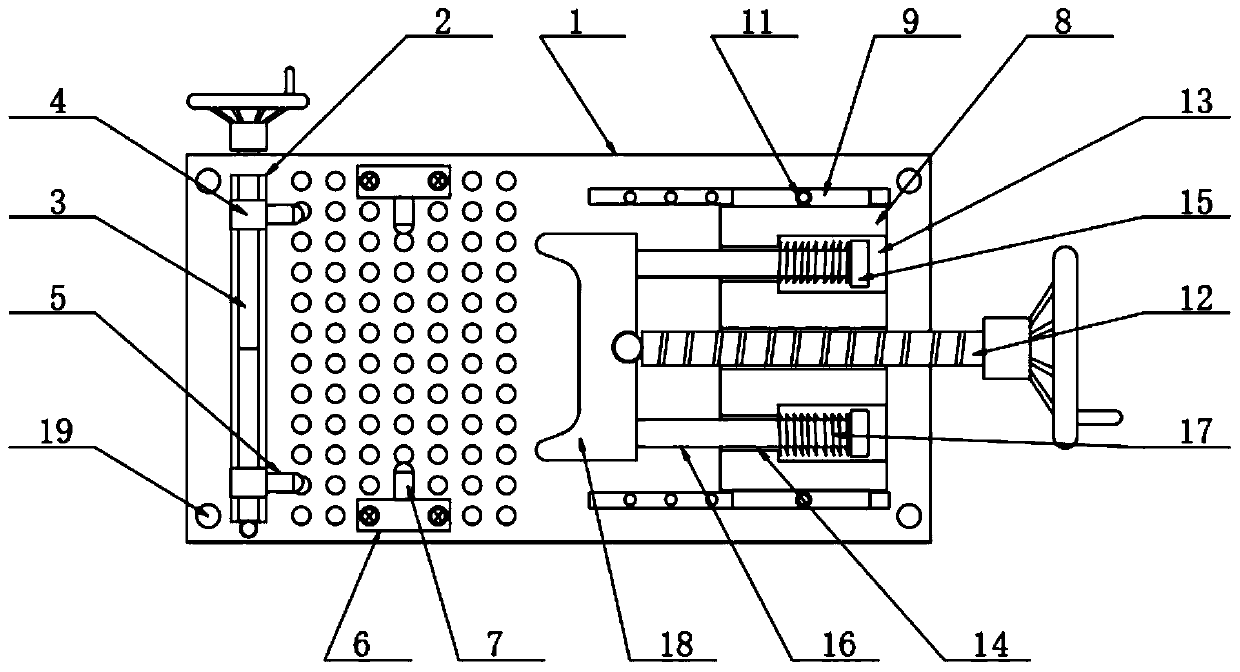

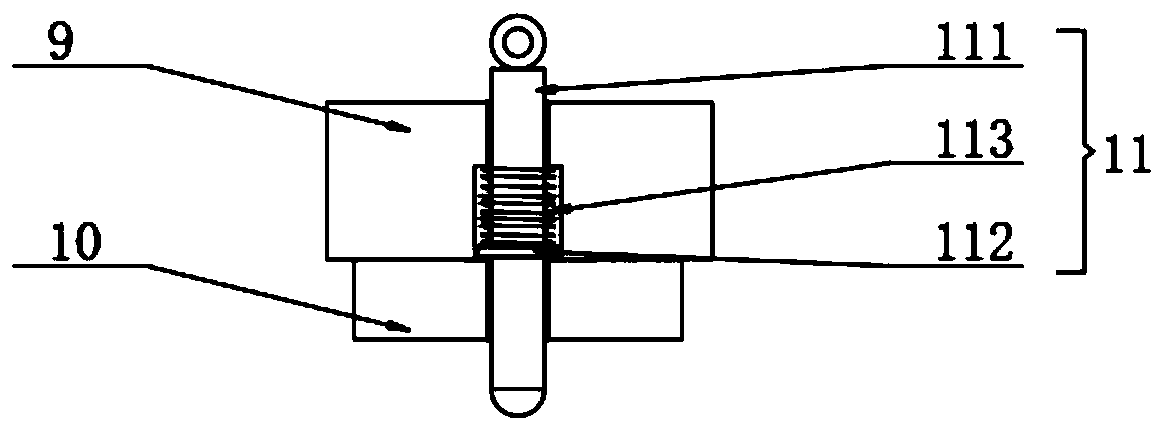

[0024] Embodiment: The fixture plate 1 is installed at a specified position through the mounting hole 19, and the two-way screw rod 3 is rotated according to the shape and size of the workpiece to drive the two groups of movable blocks 4 to approach or move away from each other to adjust the position, and at the same time, the adjusted position is adjusted by the screw. The receiving block 6 is fixedly connected with the top of the fixture plate 1. At the same time, according to the length of the workpiece, adjust the mounting block 8 to a suitable position, pull the insertion rod 111 upward, and the insertion rod 111 is separated from the socket upward, and pass the sliding block 10 and the horizontal sliding groove. Adjust the position of the mounting block 8, loosen the inserting rod 111, the return spring 113 drives the inserting rod 111 to reset and snap into the corresponding socket to fix the mounting block 8, and contact the left side of the workpiece with the round head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com