Method for performing EBM metal 3D printing on personalized human body thighbone prosthesis sleeve

A 3D printing and femoral prosthesis technology, applied in the field of 3D printing, can solve problems such as the natural mismatch between the standardized artificial femoral prosthesis and the medullary cavity shape, and the cumbersome manufacturing of personalized customized femoral prostheses, and achieve a good initial fixation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are exemplified, and detailed descriptions are as follows with reference to the accompanying drawings: There is no innovation in software or methods in the present invention.

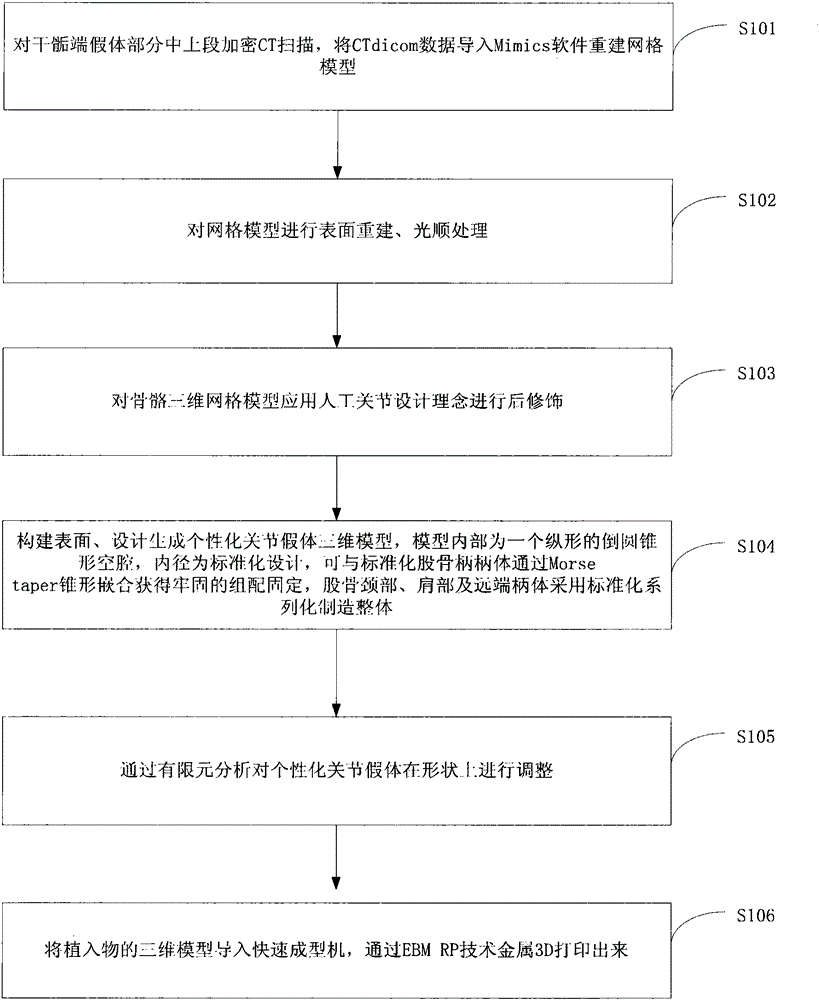

[0043] see figure 1 :

[0044] The present invention is achieved in this way, a method of EBM metal 3D printing personalized human femoral prosthesis cuff comprises:

[0045] S101. Encrypted CT scanning of the middle and upper part of the metaphyseal prosthesis, importing CTdicom data into Mimics software to reconstruct the grid model;

[0046] S102. Perform surface reconstruction and smoothing processing on the grid model;

[0047] S103. Post-modify the three-dimensional skeleton mesh model by applying the artificial joint design concept;

[0048] S104. Construct the surface, design and generate a personalized three-dimensional joint prosthesis model. The inside of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com