Self-balance fine adjusting system of welding machine

A welding machine and self-balancing technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor adjustment effect, long time, poor balance, etc., and achieve good initial fixing effect , to ensure safe work, to ensure the effect of work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

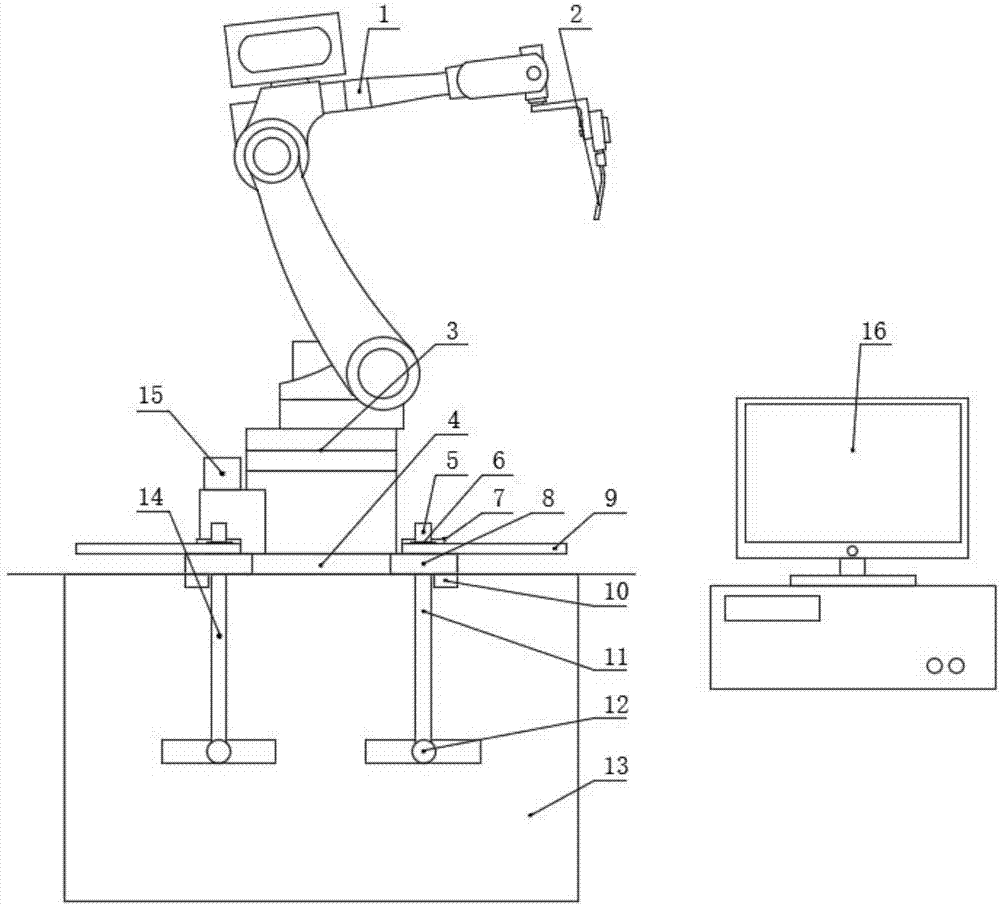

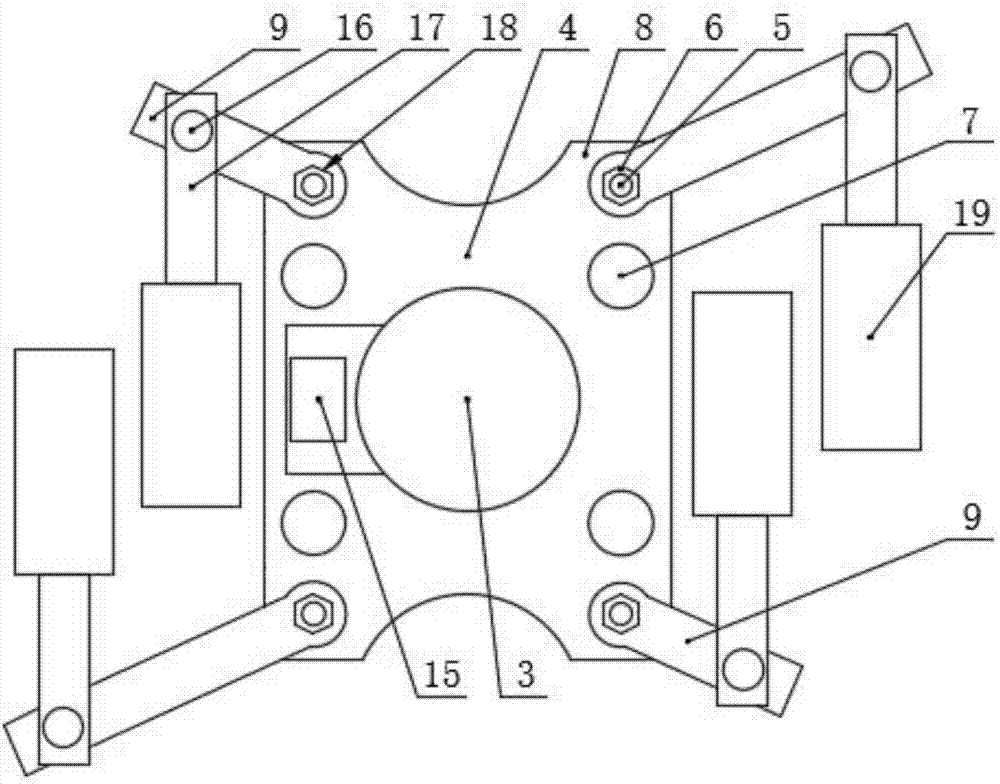

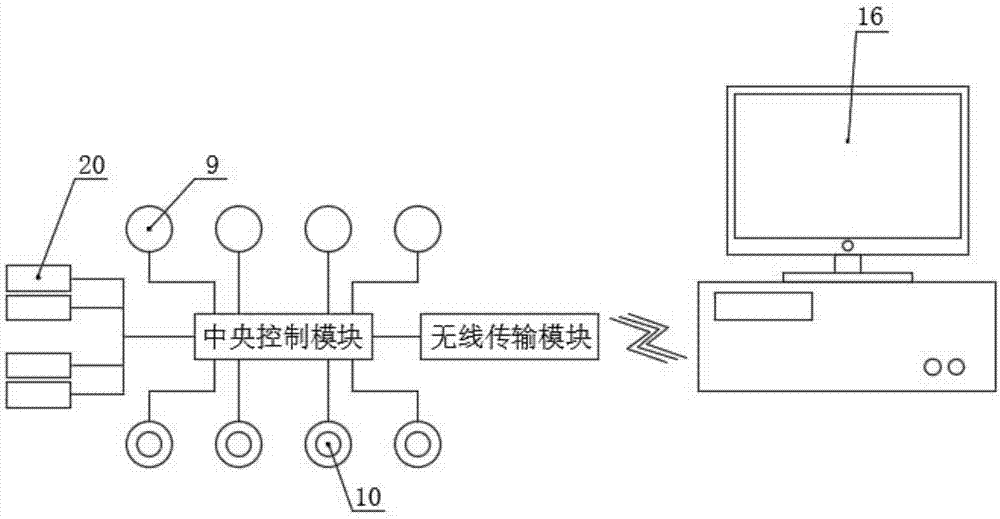

[0019] A welding machine self-balancing fine-tuning system, such as Figure 1~3 Shown, comprise welding machine 1, base 13, welding machine lower end is provided with base 4, and welding machine upper end is provided with welding torch 2, is provided with reinforcing bar 11,14 in the base, and reinforcing bar stretches out the upper end 5 of base from welding machine base The end face passes through and the fixing nut 6 is set on its outer edge. The innovation of the present invention is that a pressure sensor 10 is respectively arranged in the base below the four corners of the base, and four horizontal sensors 7 are arranged at intervals on the end face of the base. The four pressure sensors and The output signal of the level sensor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com