Round tube web girder and manufacturing method thereof

A web beam and round tube technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as the inability to fully meet the requirements of urban construction, and achieve unique aesthetic effects, good economy, and small self-weight effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a circular tube web beam, the method comprising the following steps:

[0032] Step 1: Prepare the upper flange plate 1, the lower flange plate 3 and the hollow tube 1;

[0033] Step 2: Arrange the lower flange plate 3 on the bridge support. If the bridge span is large, you need to arrange temporary supports between the bridge spans;

[0034] Step 3: Install the end beam 5 on the lower flange plate 3 at the fulcrum by welding or bolting;

[0035] Step 4: arranging the hollow tube 1 on the lower flange plate 3;

[0036] Step 5: Install the connecting piece 4 between the hollow round tube 1 and the lower flange plate 3 to connect and fix the hollow round tube 1 and the lower flange plate 3, install the connecting piece 4 between the hollow round tube 1 and make the hollow round tube 1 Fixed connection between;

[0037] Step 6: Arrange the upper flange plate 2 on the hollow circular tube 1, and install the connec...

Embodiment 1

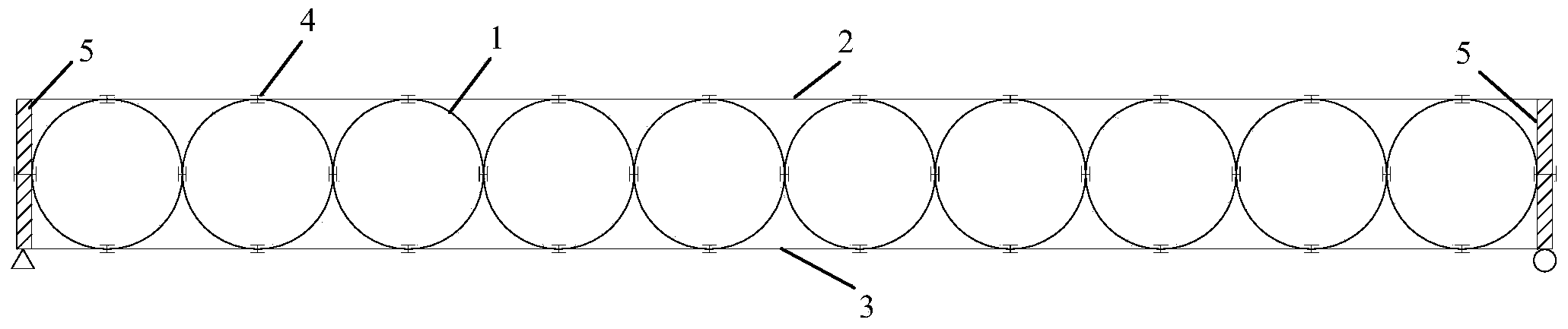

[0038] Embodiment 1: a kind of circular tube web beam, comprising a series of circular steel tubes 1 arranged sequentially along the bridge direction, the lower flange steel plate 3 connected with the circular steel tube 1 through the connector 4, and the round steel tube 1 connected with the circular steel tube 1 through the connector 4 Upper flange steel plate 2, and end beam 5.

[0039] Compared with the circular tube web beam with reinforced concrete, the circular tube web beam with steel structure is lighter in weight, but the cost is higher. Due to the light weight, the construction process of factory prefabrication and on-site assembly can be adopted during construction. The amount of on-site construction is small and the construction speed is fast. It is more suitable for bridge projects that require rapid construction (such as temporary bridges that require rapid construction), or bridge projects that require small self-weight.

[0040] Proceed as follows:

[0041]...

Embodiment 2

[0048] Embodiment 2: A circular tube web beam, including a series of reinforced concrete circular tubes 1 arranged sequentially along the bridge direction, a reinforced concrete lower flange plate 3 connected to the circular tubes 1 through connectors 4, and connected to the circular tubes through Reinforced concrete upper flange plate 2 connected by piece 4.

[0049] Compared with the circular tube web beam with steel structure, the circular tube web beam with reinforced concrete structure is heavier, but the cost is lower. Due to the heavy weight, factory prefabrication and on-site cast-in-place flange plate construction techniques can be used during construction. Although the circular tube web beam with reinforced concrete flange plate has a large structural weight, the surface of the structure does not need anti-rust coating.

[0050] Proceed as follows:

[0051] 1) Hollow round pipes are prefabricated in the factory and delivered to the site;

[0052] 2) Arrange temporar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com