Multi-dimensional energy dissipation and seismic mitigation type cold-formed thin-walled steel structure residential system

A technology for cold-formed thin-walled steel and residential buildings, which is applied in residential construction, earthquake-proof, building components, etc., can solve the problems of insufficient seismic capacity and reduced reliability, and achieves the improvement of frictional energy dissipation capacity, increase energy dissipation capacity, and improve Effects of Plastic Deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

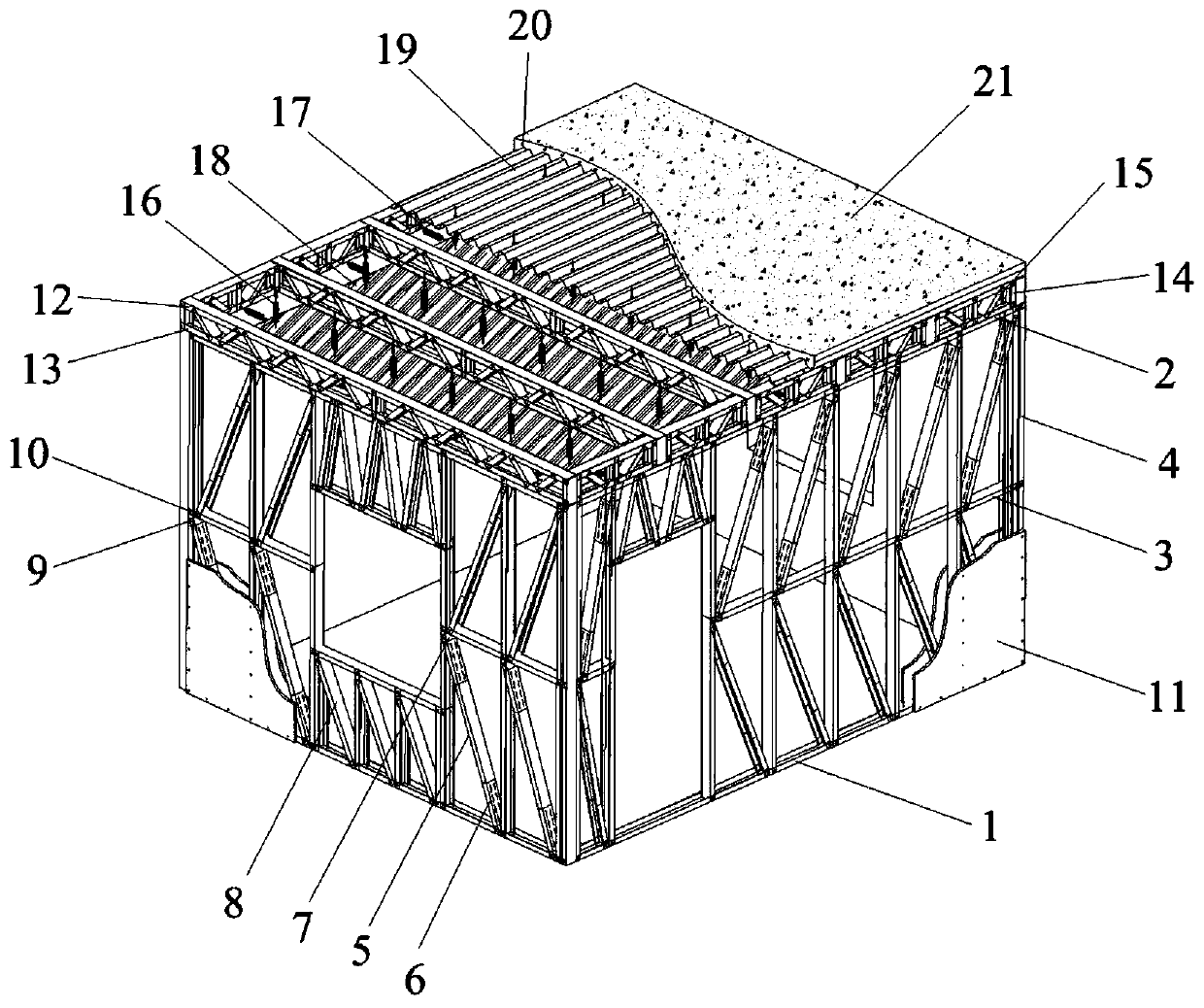

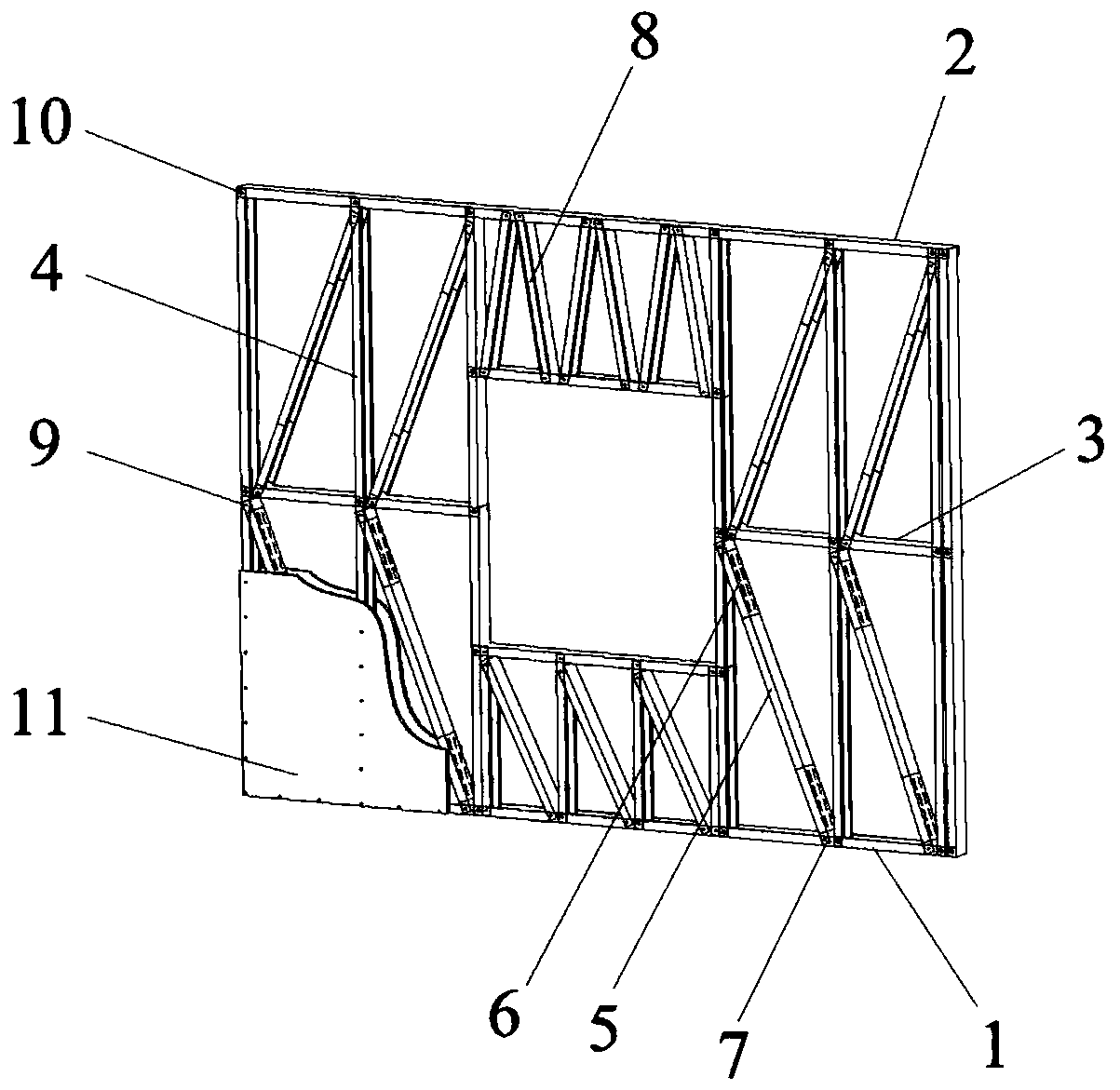

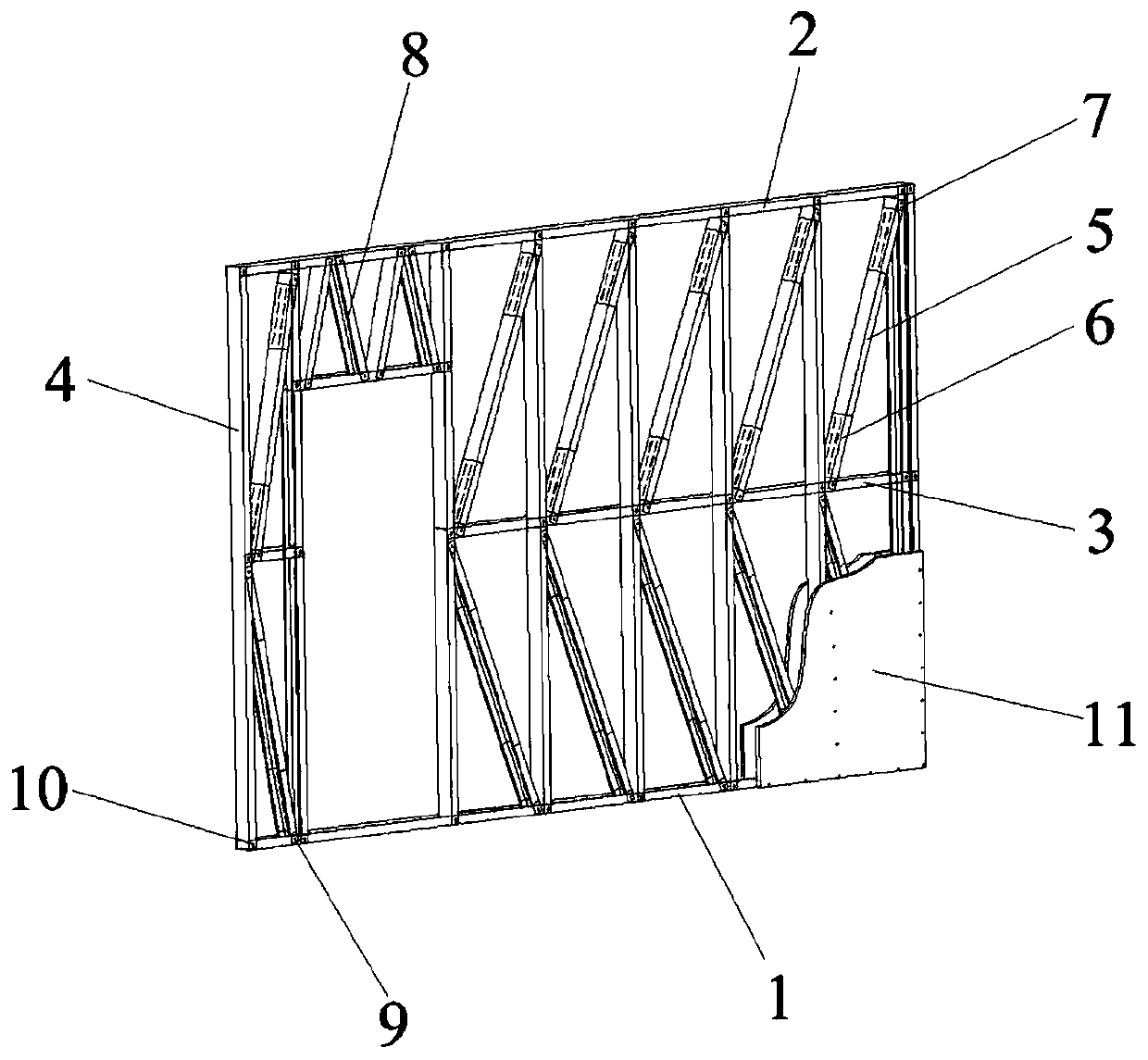

[0048] Such as figure 1 Shown is an embodiment of a multi-dimensional energy dissipation and shock absorption type cold-formed thin-walled steel structure residential system of the present invention, which mainly includes: bottom rail 1, top rail 2, horizontal brace 3, wall pillar 4, energy dissipation oblique Support middle part 5, energy-consuming oblique brace yield section 6, energy-consuming oblique brace end 7, rigid oblique brace 8, self-tapping screw 9, friction washer 10, cladding plate 11, truss upper chord 12, truss lower chord 13, truss Column 14, truss stay 15, chemical bolt spring 16, bolt spring 17, quality steel plate 18, corrugated steel plate 19, steel mesh 20 and lightweight concrete slab 21.

[0049] The specific implementation steps are as follows:

[0050] 1) The multi-dimensional energy dissipation and shock-absorbing cold-formed thin-walled steel structure residential system of the present invention includes four-sided cold-formed thin-walled steel walls, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com