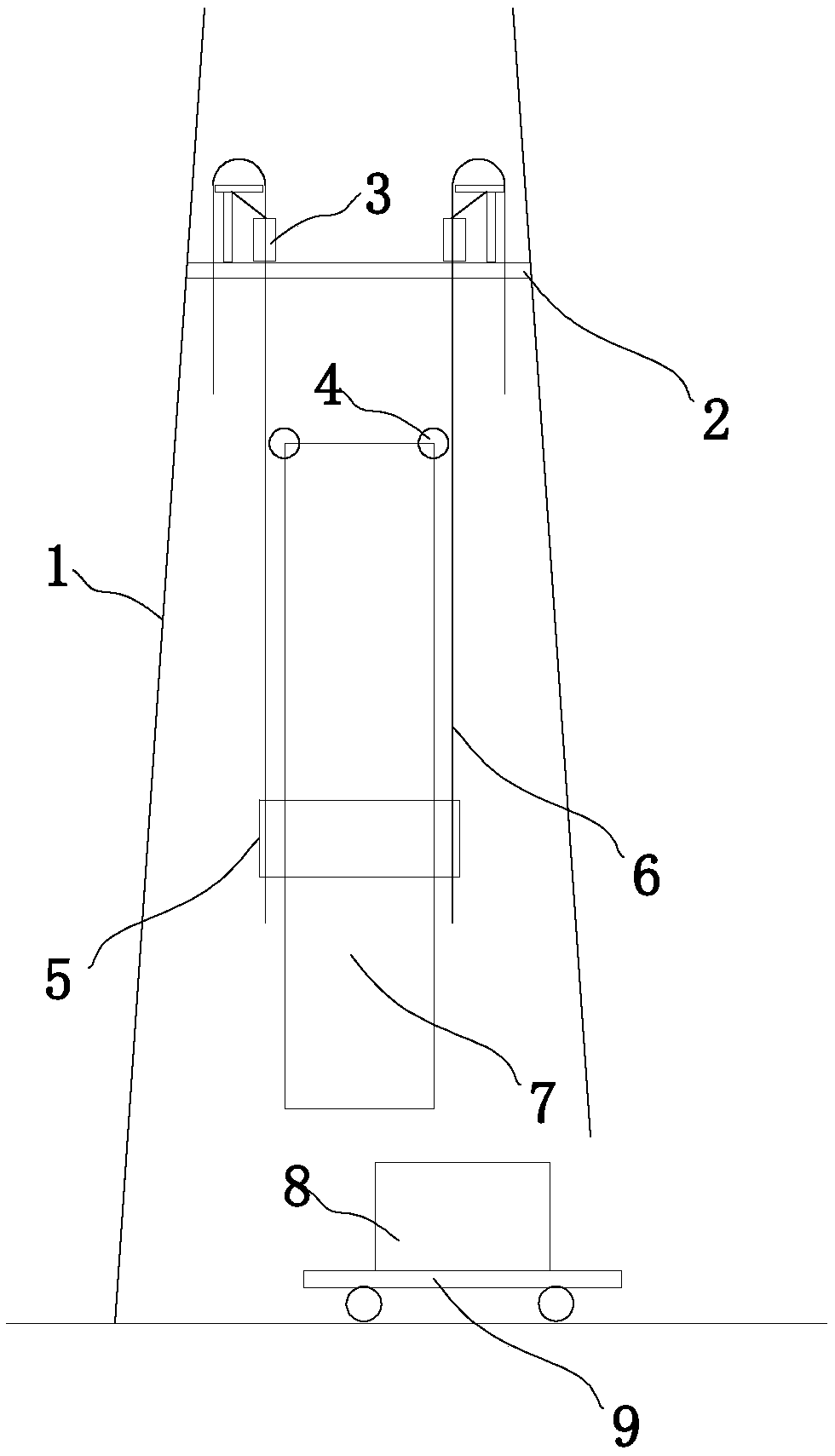

Hydraulic lifting and upside-down construction method for internal steel tube of chimney

A technology of hydraulic lifting and construction methods, which is applied in the field of building construction, can solve the problems of large hydraulic jacking equipment and steel structure systems, poor hoisting automation of hoisting hoisting methods, and high welding quality requirements, so as to reduce construction costs and reduce installation costs. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method of the present invention will be described in detail below in conjunction with specific examples.

[0027] Take the 150m high chimney as an example. The design height of the chimney is 150m, and it is sleeve type. The outer cylinder is a reinforced concrete structure with a height of 147m, and there are two inner cylinders, both of which are titanium-steel composite plate steel inner cylinders with a diameter of 3.2m. The outer diameter of the lower part of the outer cylinder is 15m, the inner diameter is 13.9m, the outer diameter of the top is 9.8m, and the inner diameter is 9.3m; the inner side of the chimney is provided with 4 circular cantilever trapezoidal corbels from bottom to top, and an inspection platform is set up, of which the elevation is 50m and 80m , 110m is a steel platform, and 144m is a combined platform.

[0028] The above chimney steel inner tube hydraulic lifting and flipping construction method includes the following steps:

[0029] S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com