Hollowed-out circular-ring-shaped space grid structure assembly type joint

A spatial grid and prefabricated technology, which is applied in the direction of building construction and construction, can solve the problems of complex node assembly steps, self-heavy, unfavorable development of prefabricated spatial structures, etc., and achieve easy control of construction quality and high degree of industrialization , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

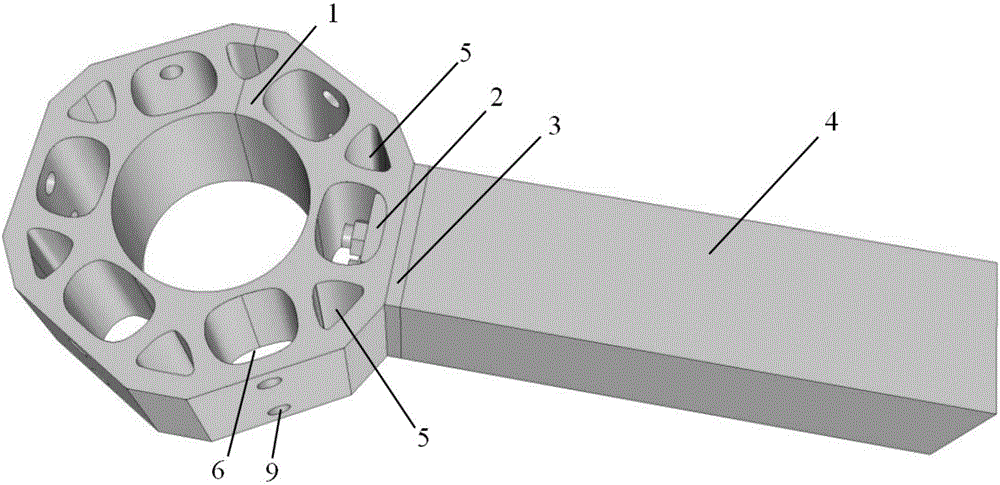

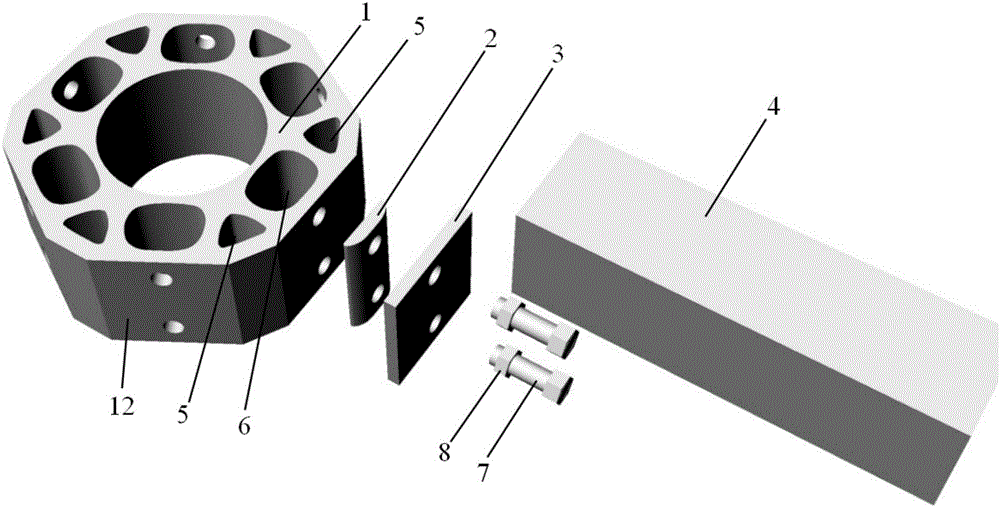

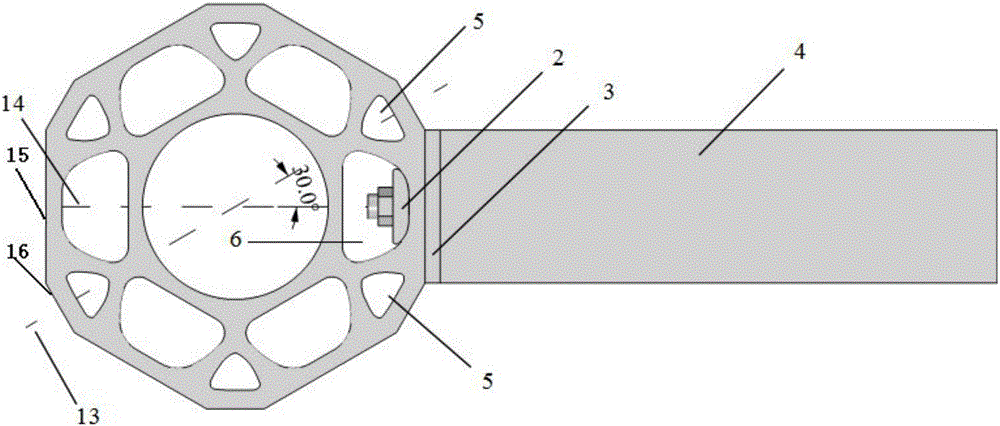

[0033] Such as Figure 1 to Figure 3 As shown, a hollowed-out annular space grid structure assembled node includes a central hollowed-out ring 1 , a joint inner gasket 2 , a sealing plate 3 , connecting rods 4 , and bolts 7 . The cross section of the central hollow ring 1 is provided with a hollow hole 1 6 and a hollow hole 2 5, and there are 6 hollow holes 6 evenly distributed along the circumferential direction of the central hollow ring 1, and each hollow hole 6 is provided with a Two third bolt holes 9 are provided on the peripheral walls of the second hollow hole 5 and the first hollow hole 6 . The outer peripheral surface of the hollow hole 6 is cut into a long side 15, and the long side 15 is parallel to the side far away from the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com