Panel unit of building external bounding system

A panel unit, building technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of poor thermal insulation effect, difficult quality assurance, heavy weight, etc., to improve the seismic performance and windproof performance, processing and installation quality. High, factory-like effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

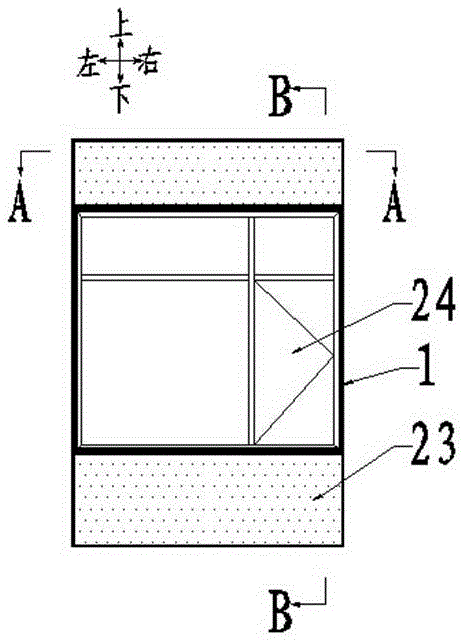

[0033] Such as Figure 1~Figure 10 As shown, a panel unit of a building enclosure system includes a unit body 23, a frame 1 is arranged around the unit body 23, and a window 24 is arranged on the unit body 23.

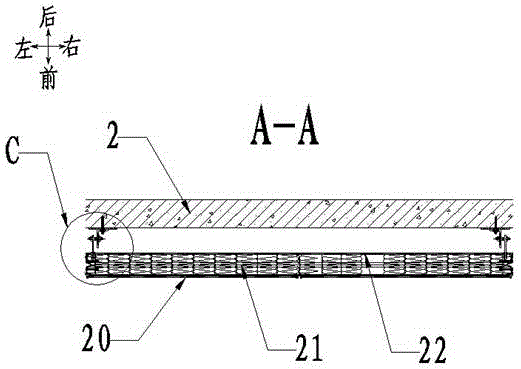

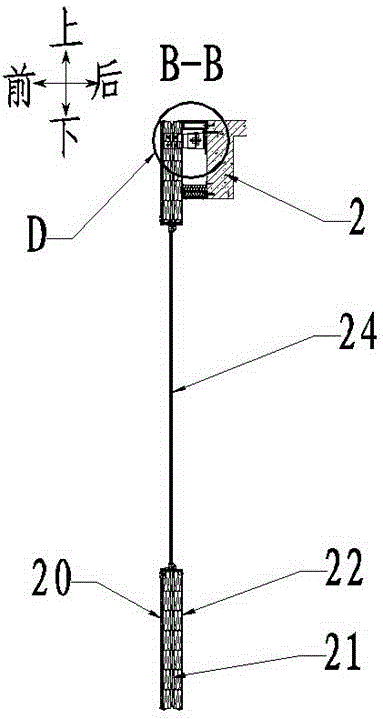

[0034] The unit body 23 includes a front panel 20, a thermal insulation board 21 and a rear panel 22 fixedly connected in sequence from front to rear, the front panel 20 and the rear panel 22 are cement pressure boards, and the thermal insulation board 21 is a rock wool belt.

[0035]The unit body 23 is fixedly connected to the frame 1 and installed on the building structural beam 2 through adjustable connectors arranged symmetrically on both sides of the unit body 23. The adjustable connectors include a first connector 6, a second The connecting piece 7 and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com