Steel-concrete combined continuous beam bridge deck as well as manufacturing method and application thereof

A technology for concrete and bridge slabs, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of intermittent laying of bridge slabs, heavy workload, and inconvenience in the construction process, so as to improve comprehensive economic benefits, high degree of industrialization, and save energy. The effect of material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

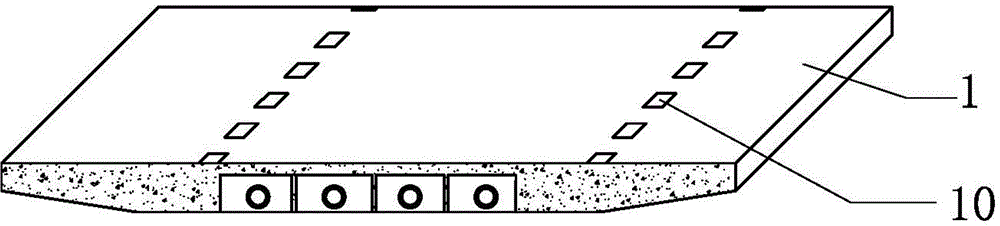

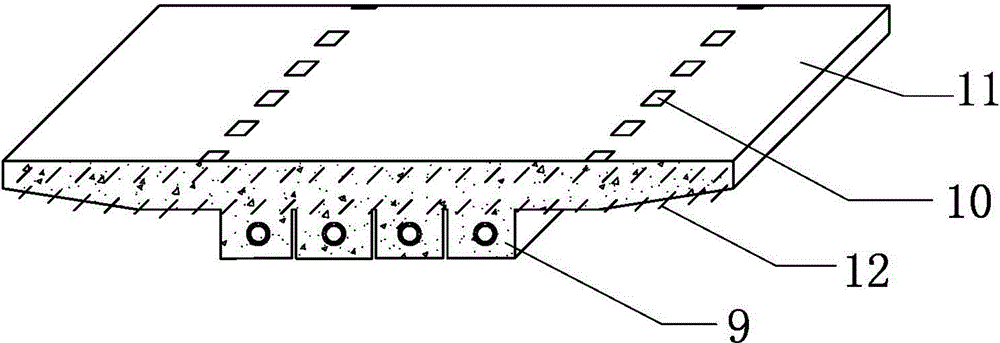

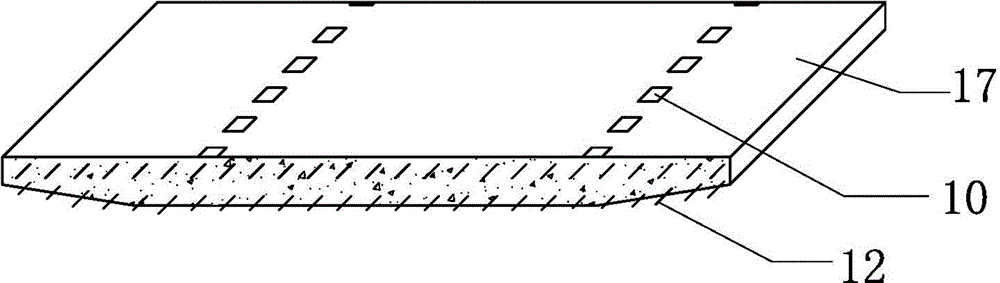

[0045] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that a steel-concrete combined continuous girder bridge deck, the bridge deck includes a concrete section plate 1 in a negative moment area, a concrete end plate 11 in a negative moment area and a concrete section plate 17 in a positive moment area;

[0046] The concrete section 1 in the negative bending moment area is arranged with longitudinal tensile steel bars 12, stirrups and bellows for installing prestressed beams 8;

[0047] The concrete end plate 11 in the negative bending moment area is provided with an anchoring end 9 at one end connected to the concrete section plate 17 in the positive bending moment area, and the concrete end plate 11 in the negative bending moment area is arranged with longitudinal tensile steel bars 12, stirrups and Install the bellows of the prestressed beam 8, and the longitudinal tensile steel bar 12 protrudes outside the concrete end plate 11 in the n...

Embodiment 2

[0080] The steel girder described in this embodiment is an I-shaped steel girder that is assembled by welding the upper flange steel plate 3 , the lower flange steel plate 5 and the web 4 , and the remainder is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com