Repair method of bar-reinforced concrete slab of continuous bar-reinforced concrete composite asphalt pavement

A technology for reinforced concrete and asphalt pavement, which is applied to the coagulation pavement, roads, roads and other directions paved on site. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

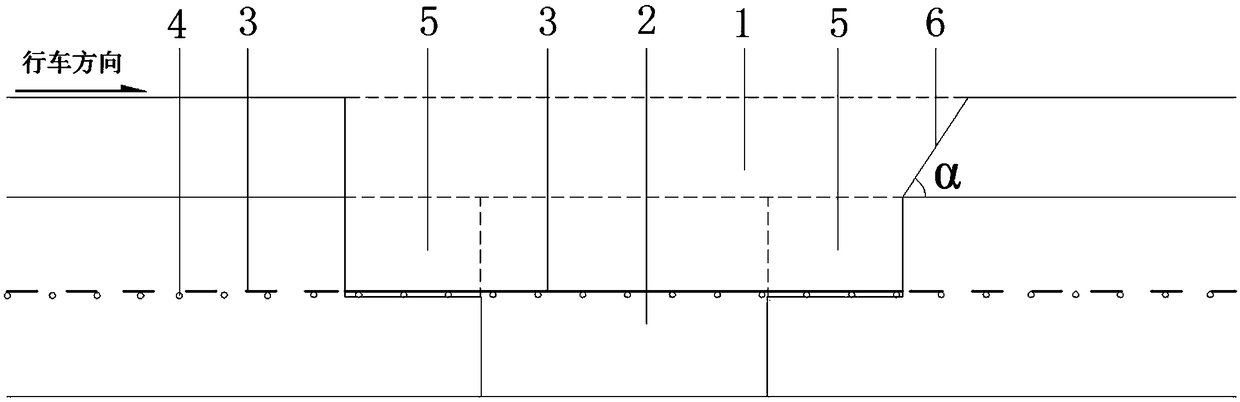

[0019] Groove the asphalt pavement in the maintenance area first to form asphalt pavement groove 1, then groove the area where the reinforced concrete slab needs to be repaired to form reinforced concrete slab groove 2, the plane size of the asphalt surface groove The length and width of the reinforced concrete slab are 20cm larger than the plane dimension; the reinforced concrete slab between the asphalt surface layer groove 1 and the reinforced concrete slab groove 2 is broken, and the longitudinal steel bar 3 in the reinforced concrete slab is broken and the transverse reinforcement 4 are just completely exposed; the longitudinal reinforcement 3 and the transverse reinforcement 4 with the same diameter as the inner diameter of the reinforced concrete slab are arranged in the reinforced concrete slab groove 2, and the longitudinal reinforcement 3 and the transverse reinforcement 4 exposed after being broken are welded on one side To form a connection, the length of the weld i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com