Prefabricated laminated steel concrete two-hole culvert

A technology of reinforced concrete and double-hole culverts, which is applied in the direction of buildings and the bottom of roads, can solve the problems of large workload, poor safety and slow progress in on-site construction, and achieve the effect of reducing construction costs, fast progress and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

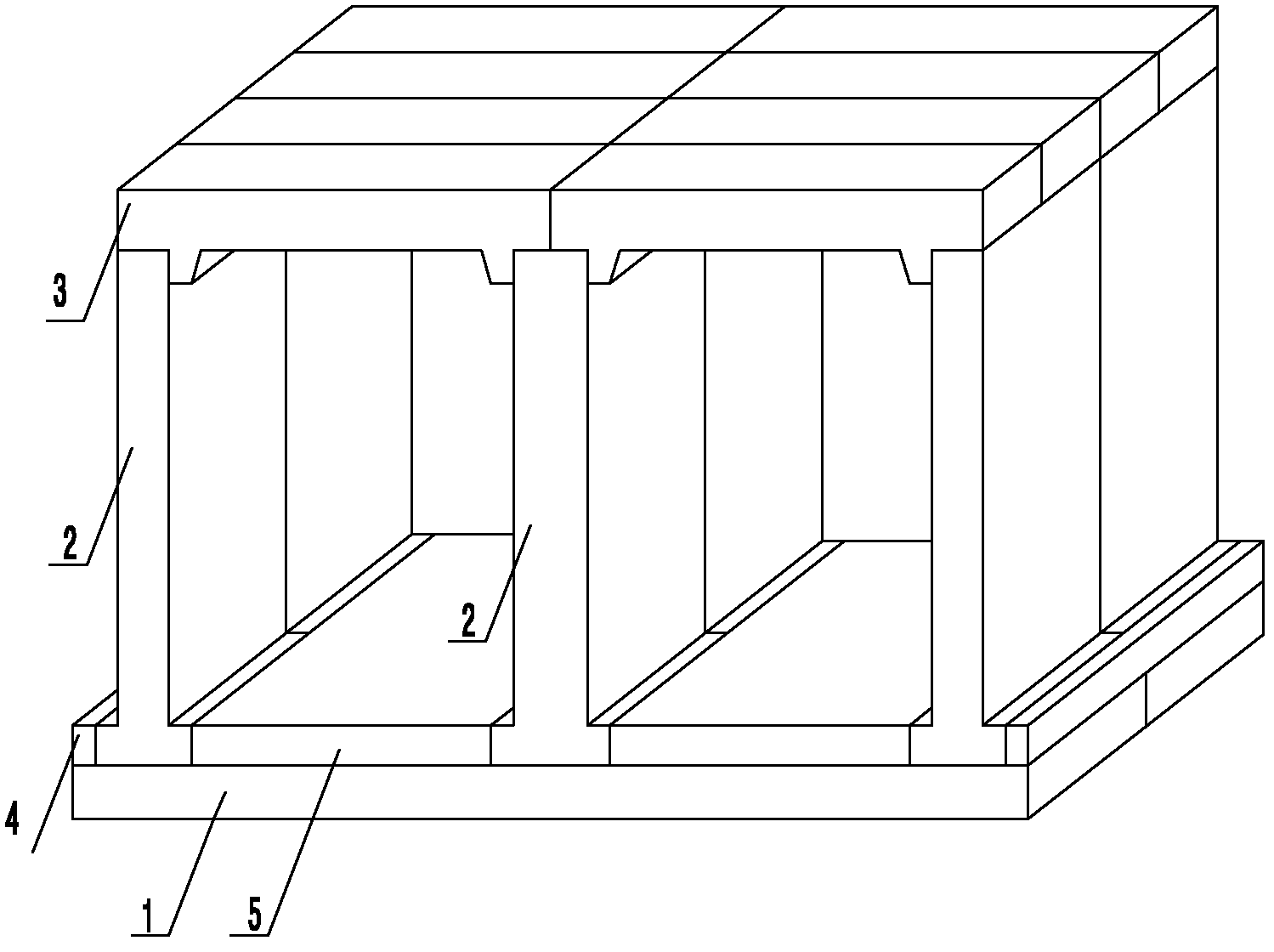

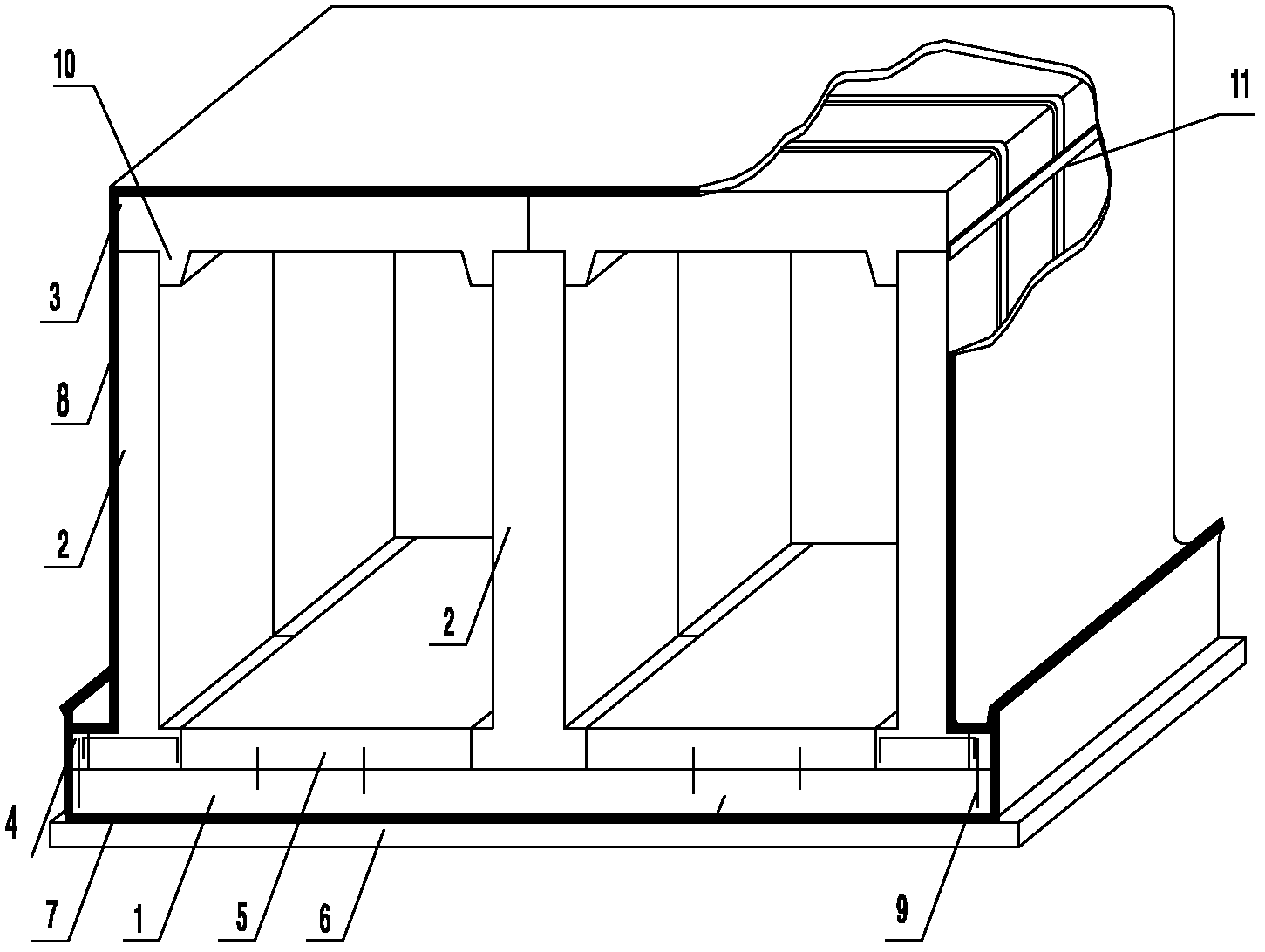

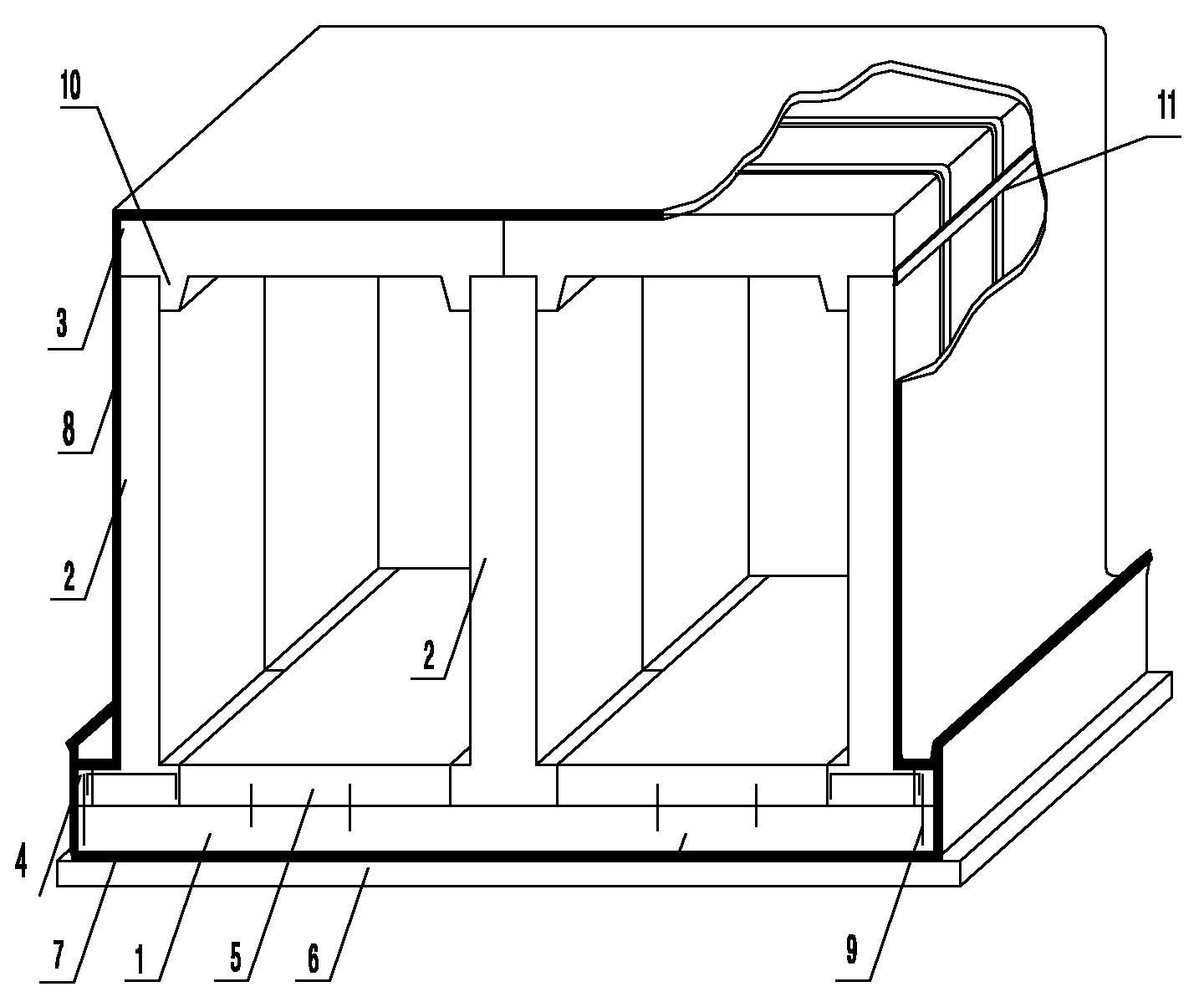

[0017] As shown in the accompanying drawings, the present invention includes a bottom plate 1, two sides, middle wall panels 2, left and right cover plates 3, cast-in-place concrete construction side strips 4, cast-in-place reinforced concrete inner bottom plate 5, bottom leveling cushion 6, Bottom waterproof board 7, upper part covers waterproof board 8 and waterproof strip 11. The bottom plate 1 is a cast-in-place plate, the two sides and the middle wall plate 2 are prefabricated inverted T-shaped wall plates, and the left and right cover plates 3 are prefabricated cover plates with corner legs 10 . The bottom leveling cushion 6 is laid on the basis of excavation; the bottom waterproof board 7 is paved on the bottom leveling cushion 6; the base plate 1 is cast-in-place on the bottom waterproof plate 7, and the concrete of the maintenance base plate 1 is made to make its strength reach Requirements: Lay out the wires on the base plate 1; after hanging the two sides and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com