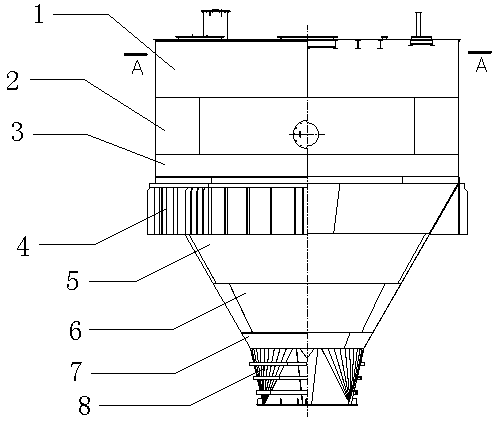

Large hopper manufacturing method

A production method and hopper technology are applied in the field of large-scale hopper production, which can solve the problems of inconvenient production of large-scale hoppers, difficult production of large-scale hoppers, and high engineering quality requirements, and achieve the effects of short construction period, reduced engineering costs, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

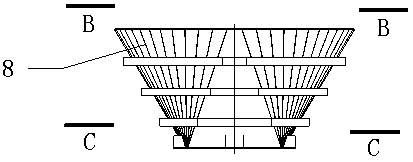

[0071] The manufacturing method of large hopper of the present invention comprises the following steps:

[0072] a, blanking, including the following steps:

[0073] (1) A36 steel plate blanking

[0074] 1) Lofting should be based on process requirements, and consider welding shrinkage allowance, cutting, planing and milling allowance; the number of materials should be marked on the steel parts with component number, part number, quantity, groove type, material, and team Information, the thickness of the stone pencil line used for stakeout and numbering shall not exceed 0.5mm, and the thickness of the elastic line of the chalk line shall not exceed 1mm;

[0075] 2) Straight strips must be cut by a multi-head straight strip machine, and special-shaped parts should be loaded and unloaded by a CNC cutting machine, and shaped steel should be unloaded by a sawing machine, profile cutting machine, and vertical cutting machine;

[0076] 3) For mechanically sheared parts, the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com