Soft soil foundation large scale steel float lock head construction method

A soft soil foundation and construction method technology, which is applied in the direction of basic structure engineering, ship locks, and ship lifting devices, can solve the problems of long construction period, high engineering difficulty, and high cost, and achieve saving construction materials, good water-stop effect, Engineering quality reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

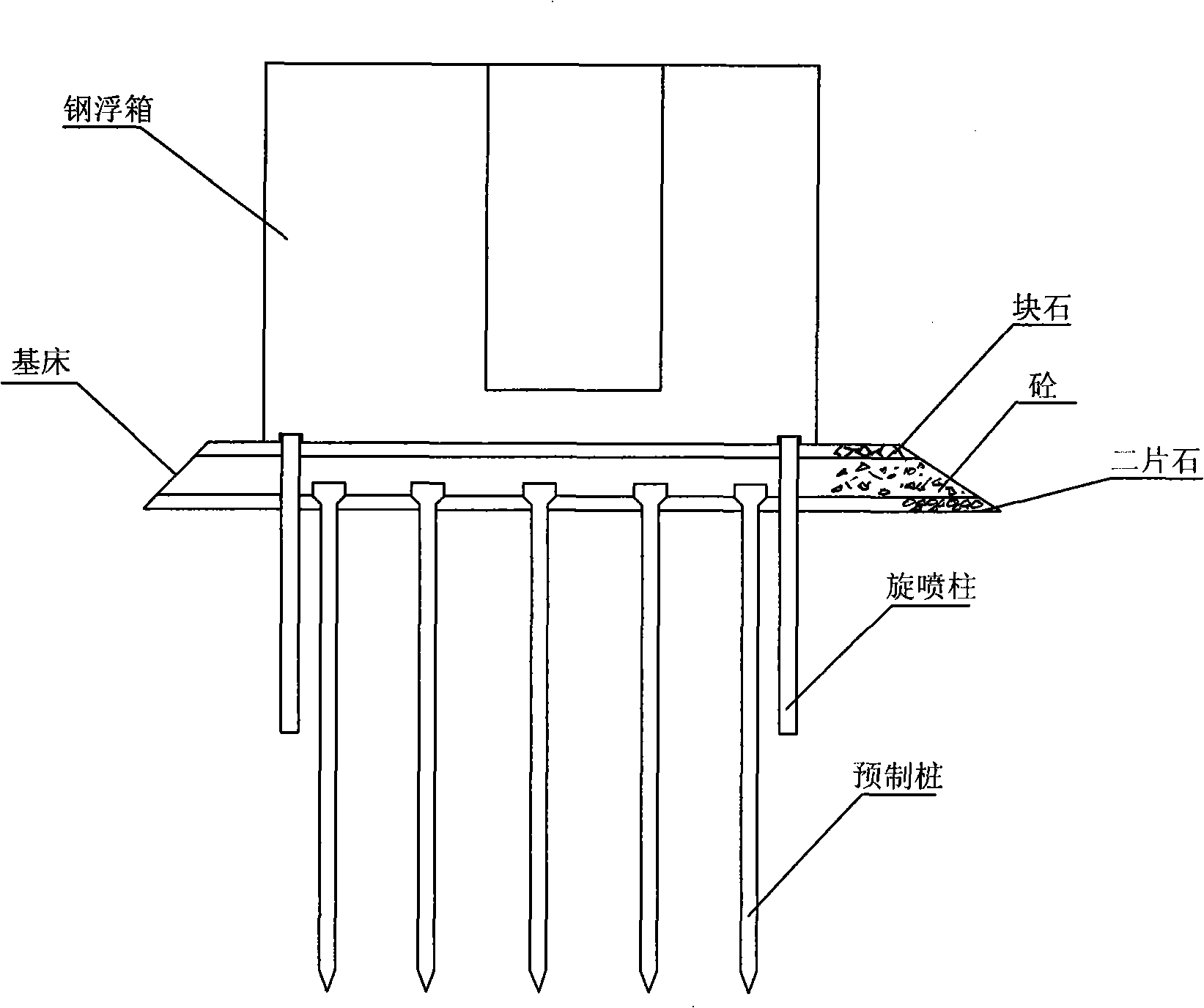

[0018] Taking a new ship lock project as an example, the geological conditions are soft soil foundation, and the front water depth is about -10.0m. The specific construction steps are as follows:

[0019] 1. Foundation trench excavation and dredging

[0020] The foundation trench is excavated to -14.2m, the width is 30m, the slope meets the design requirements, and the silt is removed.

[0021] 2. Prefabricated piles

[0022] Using water piling boats to drive piles, control elevation and check penetration, drive 600×600mm prefabricated large-headed square piles with a length of 38m into the soft soil layer under the foundation trench.

[0023] 3. Foundation bed riprap and leveling

[0024] There are two stone layers of 200mm in the bottom layer of the foundation bed, and a 1.8m concrete cushion is poured on the riprap layer. The concrete cushion needs to be wrapped around the top layer of the pile head and scraped off, and then the top layer is thrown with stones with a diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com