Construction method for H-type steel stiff column with cross fracture surface

A construction method, the technology of H-shaped steel, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of difficult control of the axis and verticality, poor seismic performance, and easy deformation, etc., and achieve high structural construction accuracy. Reliable engineering quality and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

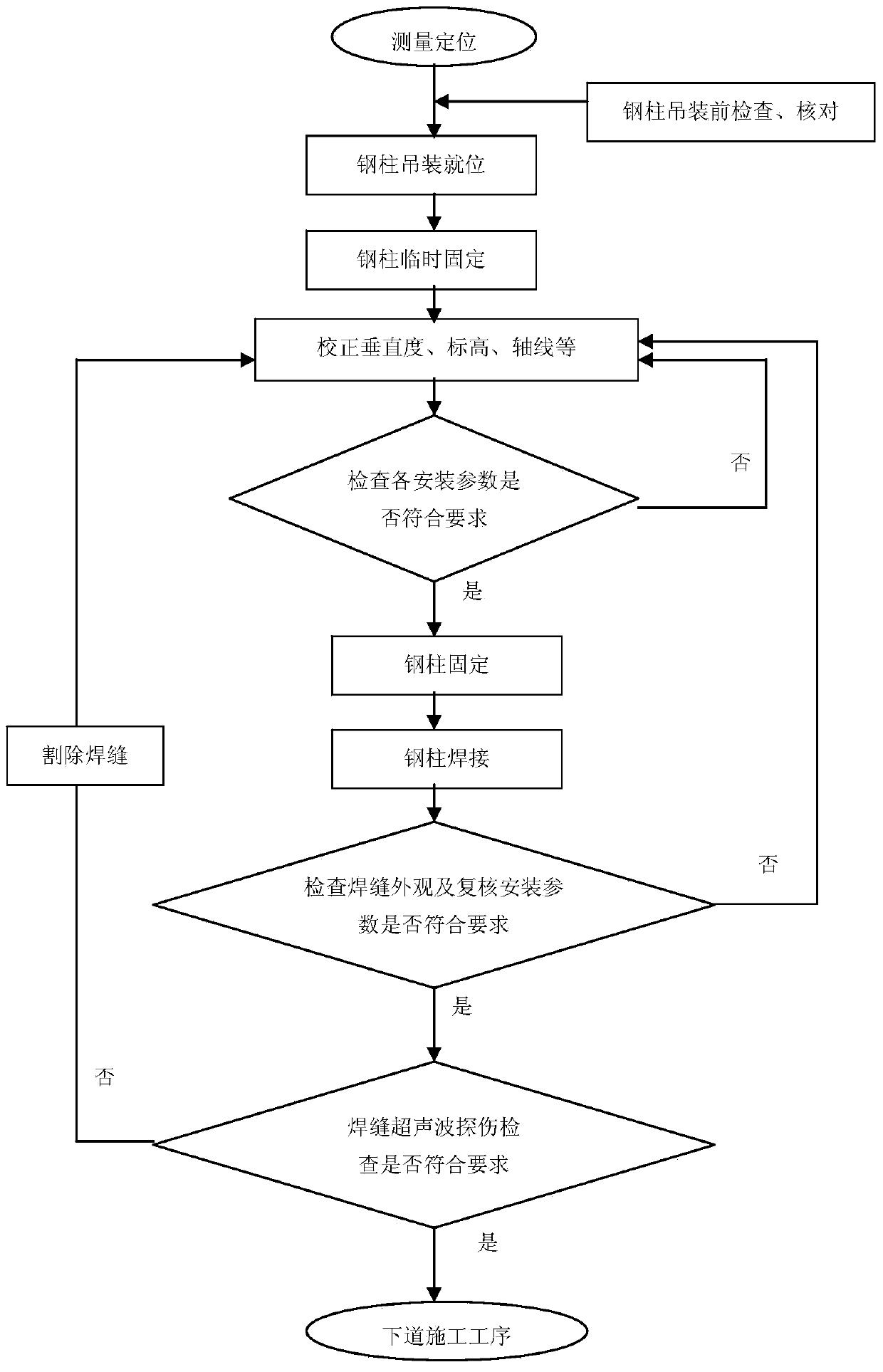

[0037] like figure 1 Shown is the flow chart of the construction method of the cross-section H-shaped steel stiff column. Specifically include the following steps:

[0038] 1. Measurement and positioning: Before installing the cross-section H-shaped steel stiff column, measure and design the embedded parts and mark the cross axis of each installed steel column, as the basis for the installation and positioning of the steel column and control the installation parameters;

[0039] (1) Calculation of control line data and layout of embedded part control lines

[0040] Calculate the relative positional relationship between each embedded part positioning template and the axis. After the first concrete pouring of the civil construction pile is completed and the construction of the waterproof protective layer is completed, the control line of the positioning formwork is respectively projected on the surface of the first pouring of the reaming pile and the surface of the cushion lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com