Overhanging set wall connector with steel pipes for exterior wall scaffold

A wall-connecting and cantilevering technology, which is applied to the attachment of scaffolding, the scaffolding supported by the building structure, the support of the building structure, etc., can solve the problem of low bearing capacity, easy deviation of the positioning of scaffolding poles, and welding of steel pipes and steel bars. Problems such as small effective area to achieve the effect of solving poor rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

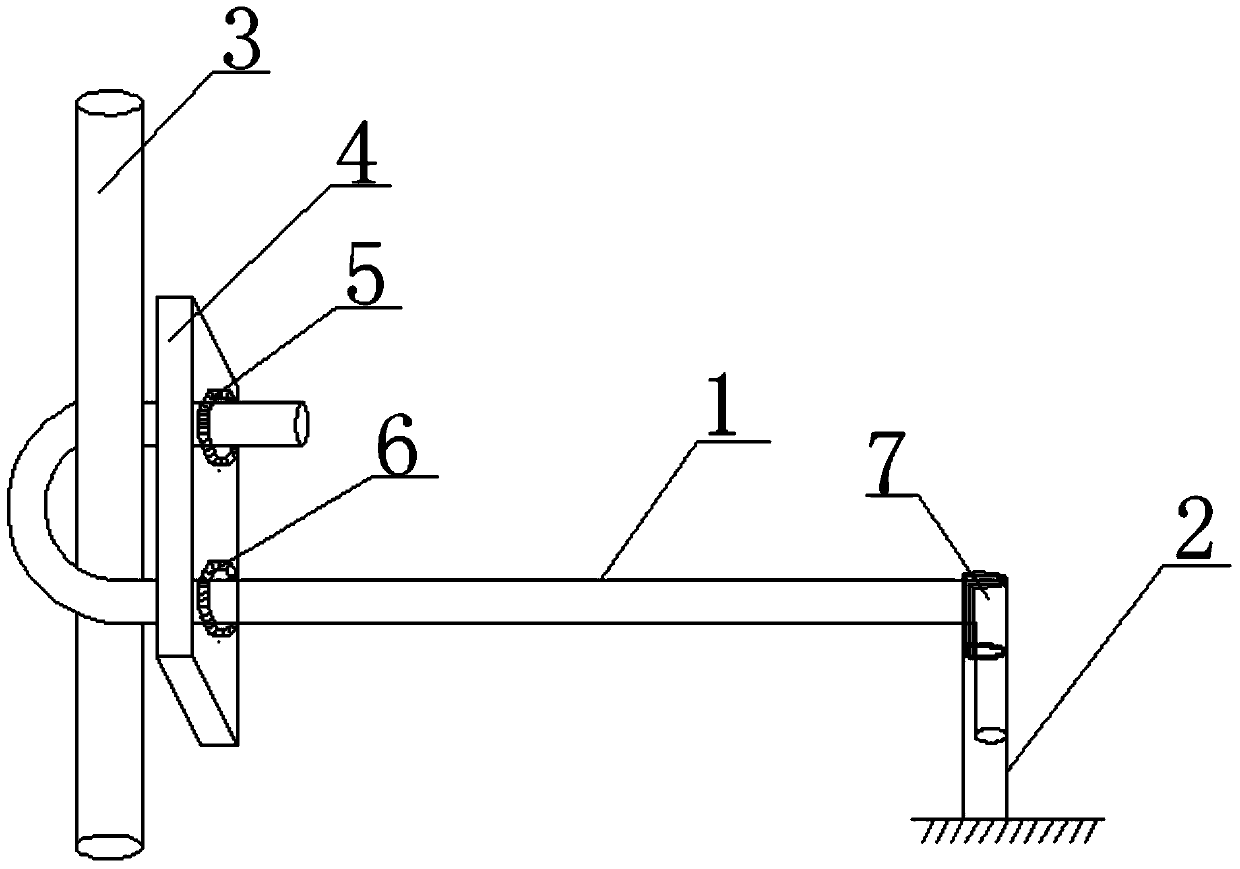

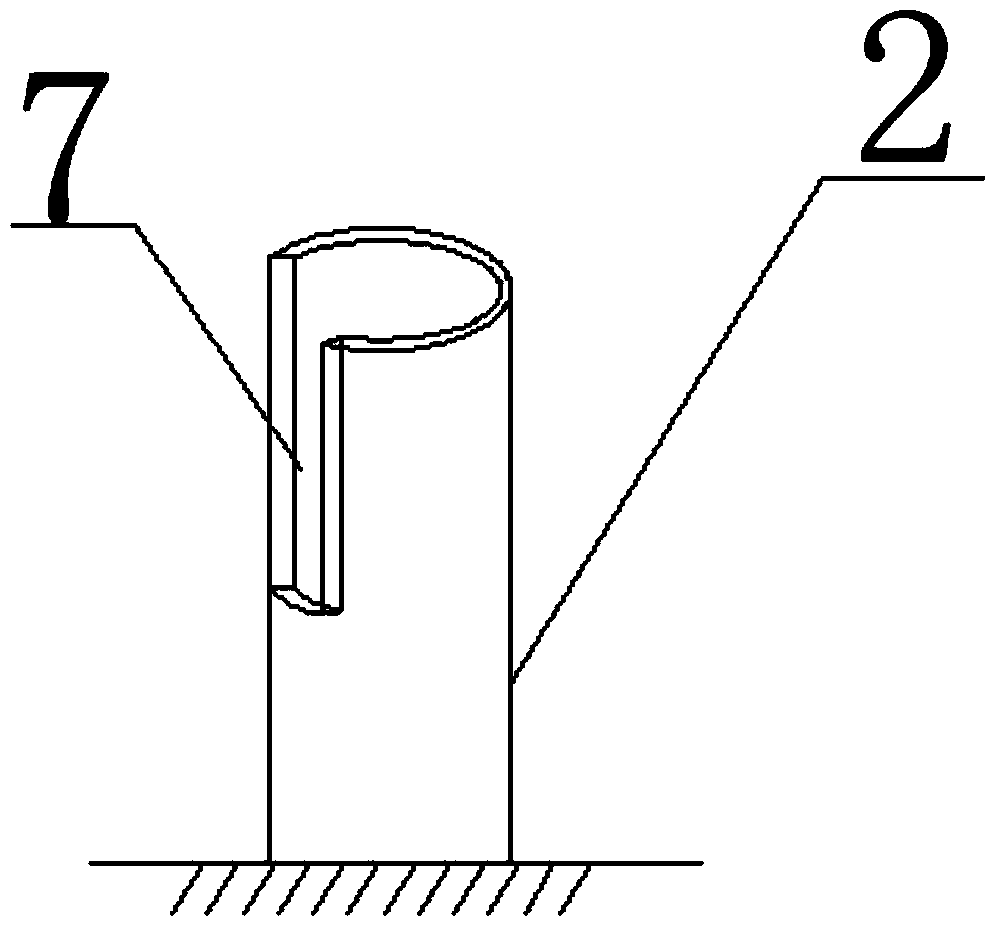

[0015] like figure 1 As shown, a cantilevered steel pipe exterior wall scaffolding stereotyped wall fittings, including stereotyped wall fittings 1, embedded sleeves 2 and stereotyped wall fitting fixing parts 4, the left fixed end of the stereotyped wall fittings 1 is cold A 180-degree hook, in the shape of a fishhook, is placed horizontally. The right side of the shaped connecting wall piece 1 is bent downward to form an "L" shape. There are two bolt holes in the middle of the shaped connecting wall piece fixing piece 4. The fixed end on the left side of the stereotyped wall piece 1 passes through the two bolt holes provided in the middle of the wall piece fixing piece 4, and uses the first bolt 5 and the second bolt 6 to vertically fix the outer pole 3, and the embedded sleeve The nozzle of the pipe 2 has a "U"-shaped groove 7, and the downward bending part on the right side of the shaped connecting wall part 1 is inserted into the embedded casing 2, and the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com