Titanium plate steel inner tank reversed construction device for chimney of thermal power station

A technology for thermal power plants and construction devices, applied in building types, buildings, towers, etc., can solve the problems of destroying the anti-corrosion structure of the inner tube of titanium plate steel, not allowing structural connections, and being unable to use it, so as to reduce the amount of steel structure processing, The effect of convenient construction and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

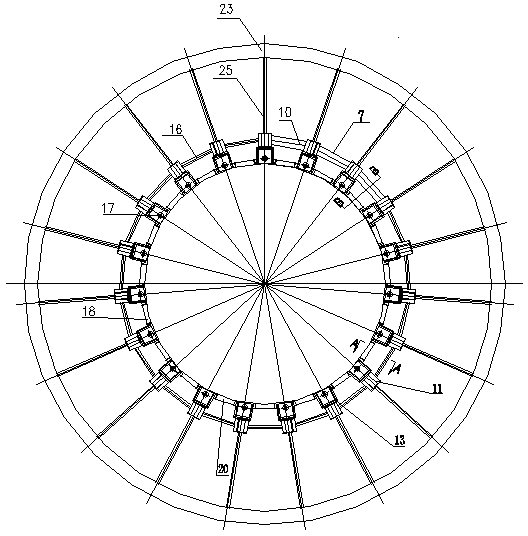

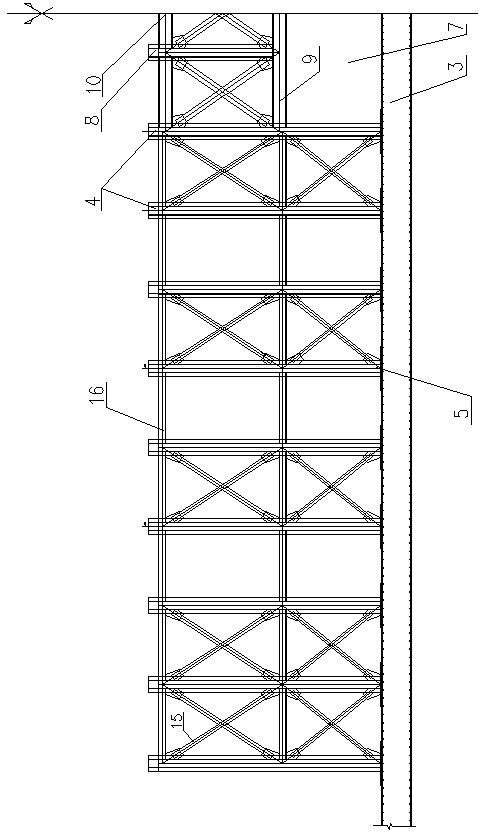

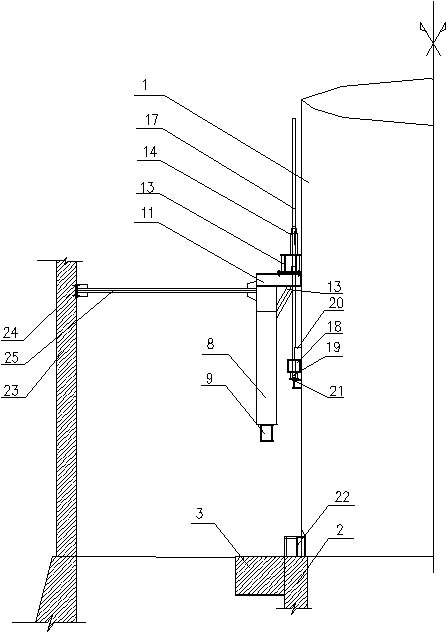

[0027] Such as Figure 1-Figure 6 As shown, the thermal power plant chimney titanium plate steel inner cylinder external hydraulic lifting and flip-chip construction device has a lifting system foundation 3 arranged on the outside of the steel inner cylinder foundation 2 along the circumferential direction. The lifting system foundation 3 is a reinforced concrete structure, and the lifting system Foundation 3 needs to ensure that the foundation bearing capacity meets the requirements. If it is backfill, the backfill must be backfilled in layers and compacted. The hoisting system foundation 3 is provided with a ring-shaped steel structure support system along the circumferential direction. The ring-shaped steel structure support system includes the feed inlet side support steel column 4 and the main support steel column 5 installed on the lifting system foundation 3 through the anchor bolts 6, the feed inlet side support steel column 4, the main support steel column 5 All are ...

Embodiment 2

[0030] Such as Figure 7-Figure 8 as shown in Figure 1-Figure 5 As shown, the thermal power plant chimney titanium plate steel inner cylinder external hydraulic lifting and flip-chip construction device includes a lifting system foundation 3 arranged on the outside of the steel inner cylinder foundation 2 along the circumferential direction. The lifting system foundation 3 is a reinforced concrete structure, and the lifting system Foundation 3 needs to ensure that the foundation bearing capacity meets the requirements. If it is backfill, the backfill must be backfilled in layers and compacted. The foundation 3 of the lifting system is provided with the feed inlet side support steel column 4 and the main support steel column 5 along the circumferential direction through the anchor bolts 6, and the feed inlet side support steel column 4 and the main support steel column 5 are combined welded H-shaped steel , the strength of the supporting steel column 4 on the side of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com